A kind of steel for mobile offshore platform with yield ratio≤0.65 and production method

An offshore platform and mobile technology, which is applied to the steel and production fields of mobile offshore platforms with a yield ratio of ≤0.65, and achieves the effects of excellent welding performance, simple production process and good cold bending performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

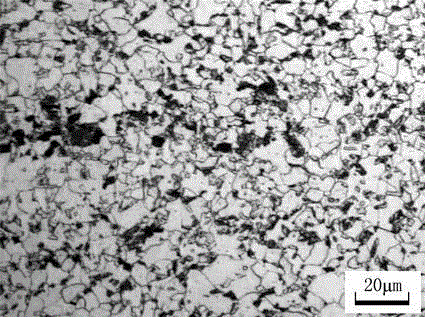

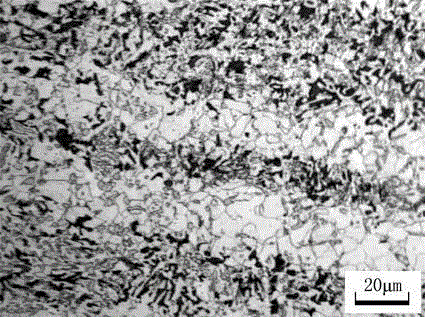

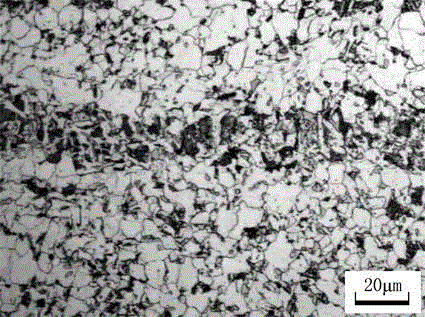

Image

Examples

Embodiment Construction

[0035] The present invention is described in detail below:

[0036] Table 1 is the value list of each embodiment of the present invention and comparative example;

[0037] Table 2 is the main process parameter list of each embodiment of the present invention and comparative example;

[0038] Table 3 is a list of performance monitoring conditions of each embodiment of the present invention and comparative examples.

[0039] Each embodiment of the present invention is produced according to the following steps:

[0040] 1) Smelted in a converter and continuously cast into billets;

[0041] 2) Heating the slab, controlling the heating temperature at 1200~1250℃, and the heating time at 200~300min;

[0042] 3) Rough rolling is carried out after conventional high-pressure descaling, and the starting rolling temperature is controlled at 1000~1150°C, the rolling speed of the widening pass is 0.5~3.0m / s, and the rolling speed of the longitudinal rolling pass is 1.0~4.0m / s s, the tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com