Production method of steel for high-strength saw blade for mines

A production method and high-strength technology, applied in the field of iron and steel smelting, can solve problems such as high carbon content, easy segregation, and large environment of oil quenching smoke, and achieve the effects of low segregation degree and carbon equivalent, good plasticity and welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

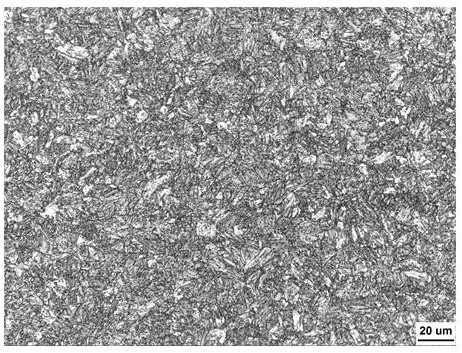

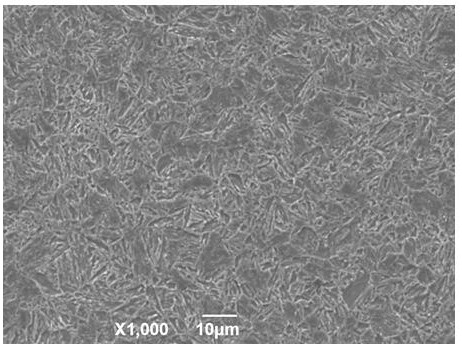

Image

Examples

Embodiment 1

[0033]The production method of steel for high-strength saw blades in mines, the process route is converter→LF furnace→RH furnace→continuous casting→rolling→quenching→tempering→performance inspection, the chemical composition is shown in Table 1, and the key process steps are:

[0034] (1) Converter: tapping C content 0.08%, P content 0.011%, tapping temperature 1608°C, adding ferrosilicon and metal manganese alloy for alloying during tapping, adding aluminum and iron for deoxidation, adding appropriate amount of lime, pre-melting Slag slag production, outbound Als content 0.035%;

[0035] (2) LF furnace: add lime and pre-melted slag totaling 13.8kg / t molten steel, add SiC 1.0kg / t molten steel and Al particles SiC0.3kg / t, the Als content of molten steel process is 0.02% ~ 0.05%; C, Si, After the Mn and S elements are adjusted to the required range, the white slag is kept for 28 minutes, ferro-titanium is added before leaving the station, the Ti content of the station is 0.085%,...

Embodiment 2

[0041] The production method of steel for high-strength saw blades in mines, the process route is converter→LF furnace→RH furnace→continuous casting→rolling→quenching→tempering→performance inspection, the chemical composition is shown in Table 1, and the key process steps are:

[0042] (1) Converter: tapping C content 0.07%, P content 0.009%, tapping temperature 1616°C, adding ferrosilicon and metal manganese alloy for alloying during tapping, adding aluminum and iron for deoxidation, adding appropriate amount of lime, pre-melting Slag slag production, outbound Als content 0.029%;

[0043] (2) LF furnace: add lime and pre-melted slag totaling 14.2kg / t molten steel, add SiC 0.9kg / t molten steel and Al particles SiC0.4kg / t, the Als content of molten steel process is 0.02% ~ 0.05%; C, Si, After the Mn and S elements are adjusted to the required range, the white slag is kept for 37 minutes, ferro-titanium is added before leaving the station, the Ti content of the station is 0.087%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com