A balance ring brine filling device

A filling device and gimbal technology, applied in the field of gimbal air tightness detection devices, can solve the problems of affecting the production process of gimbal, many human participation factors, poor filling effect, etc., so as to solve the problem of less labor and high filling effect. , the effect of reducing management costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described below in conjunction with accompanying drawing.

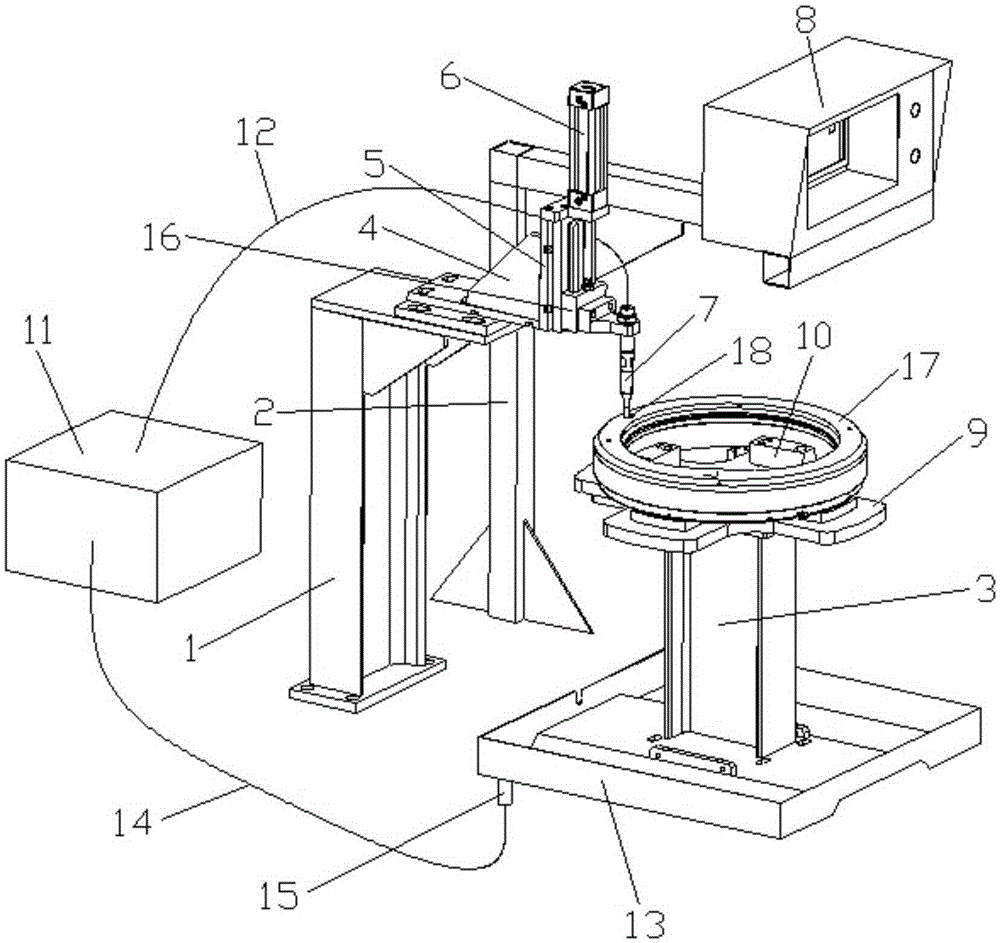

[0014] as attached figure 1 The shown balance ring brine filling device of the present invention includes a bracket 1, a support frame 2, a fixing frame 3, an adjusting tripod 4, a fixing block 5, a cylinder 6, a brine filling head 7, and a brine filling control Box 8, workbench 9, balance ring fixed block 10, water storage tank 11 and water inlet pipe; the support 1, support frame 2 and fixed frame 3 are arranged on the same reference level; the top of the support 1 is provided with an adjustment tripod 4; the outer end of the adjustable tripod 4 is connected with a fixed block 5; the fixed block 5 is provided with a cylinder 6; the telescopic rod of the cylinder 6 passes through the fixed block 5; the telescopic rod of the cylinder 6 passes through the fixed block 5; The end of the fixed block 5 is provided with a brine filling head 7; the brine filling control box 8 is arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com