Simultaneous slip-form construction device of multi-limb high pier

A construction device and high pier technology, which is applied in the field of multi-leg thin-walled hollow high pier simultaneous sliding form construction device, can solve the problems of high cost, construction quality, difficult safety control, long construction period, etc., to reduce investment and shorten The construction period and the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

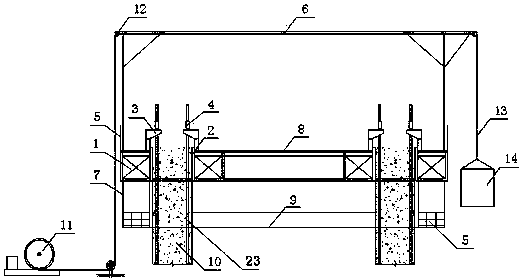

[0019] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

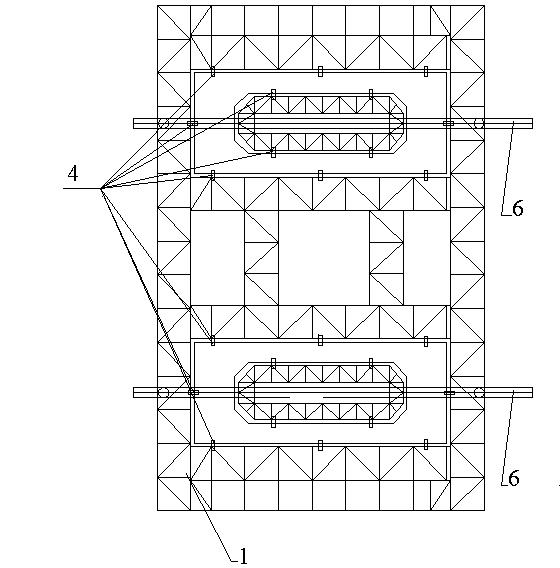

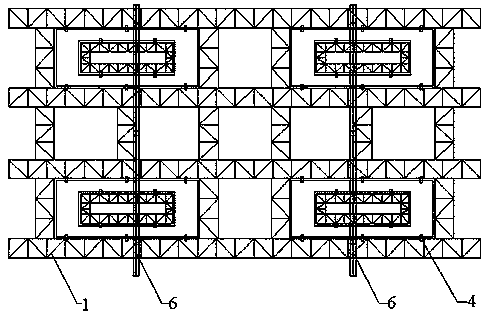

[0020] 1. The multi-leg hollow high pier co-sliding construction device includes the sliding form part, the operating platform, the lifting part and the material transportation part. The sliding form part includes the panel 2 of the multi-leg high pier and the symmetrical structure connecting these panels 2 into one truss. The lifting part includes a lifting frame; the material transportation part includes a gantry. The lifting part is lifted upwards, the lifting part drives the truss, and the truss drives each panel to move upwards as a whole, and the entire operation platform slides upwards together, forming a multi-legged hollow high pier that slides together.

[0021] Two, the construction structure of the sliding form body of the present invention is as follows:

[0022] 1. Truss

[0023] The truss is used to support and strengthen the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com