Ultrasonic vacuum preloading method

A vacuum preloading method and ultrasonic technology, which are applied in soil protection, construction, infrastructure engineering, etc., can solve the problems of blockage, vacuum degree transfer and drainage consolidation effect in silty soil area, and poor construction effect of silty soil. and other problems, to achieve the effect of saving construction costs and speeding up the flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

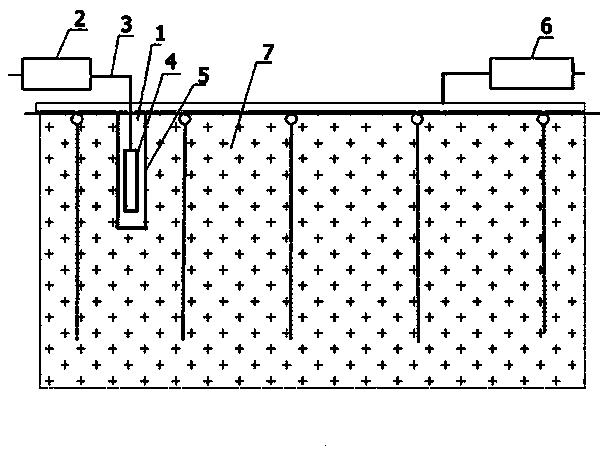

[0024] Such as figure 1 As shown, the construction operation of implementing the ultrasonic vacuum preloading method on a soft foundation treatment area of silty soil is carried out according to the following implementation steps:

[0025] 1) Arrange ultrasonic operation point 1 in the vacuum preloading soft ground treatment area;

[0026] 2) Install the ultrasonic power supply 2 in the vacuum preloaded soft ground treatment area, and connect the ultrasonic power supply 2 to the ultrasonic transducer 4 through the special ultrasonic cable 3;

[0027] 3) During the construction work of vacuuming and drainage consolidation by the vacuum device 6 in the vacuum preloading construction, start the ultrasonic power supply 2, and use the ultrasonic transducer 4 at the ultrasonic operation point 1 to treat the soft soil layer in the soft foundation treatment area 7 Perform ultrasonic treatment.

[0028] During the construction of soft ground treatment by ultrasonic vacuum preloadi...

Embodiment 2

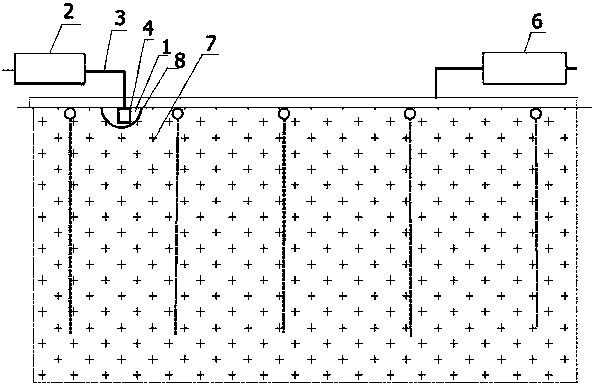

[0032] Such as figure 2 As shown, the construction operation of ultrasonic vacuum preloading method is implemented in a soft foundation treatment area of muddy soil:

[0033] 1) Arrange ultrasonic operation point 1 in the vacuum preloading soft ground treatment area;

[0034] 2) Install the ultrasonic power supply 2 in the vacuum preloaded soft ground treatment area, and connect the ultrasonic power supply 2 to the ultrasonic transducer 4 through the special ultrasonic cable 3;

[0035] 3) During the construction work of vacuuming and drainage consolidation by the vacuum device 6 in the vacuum preloading construction, start the ultrasonic power supply 2, and use the ultrasonic transducer 4 at the ultrasonic operation point 1 to treat the soft soil layer in the soft foundation treatment area 7 Perform ultrasonic treatment.

[0036] During the construction of soft ground treatment by ultrasonic vacuum preloading method, every 100m of the vacuum preloaded soft ground treatme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com