Novel anti-theft door manufacturing technology

A new technology, anti-theft door technology, applied in the direction of preventing theft, door leaf, anti-war damage, etc., can solve the problems of high product cost, low profit, low efficiency, etc., and achieve the effect of reasonable equipment, labor saving, and multi-economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

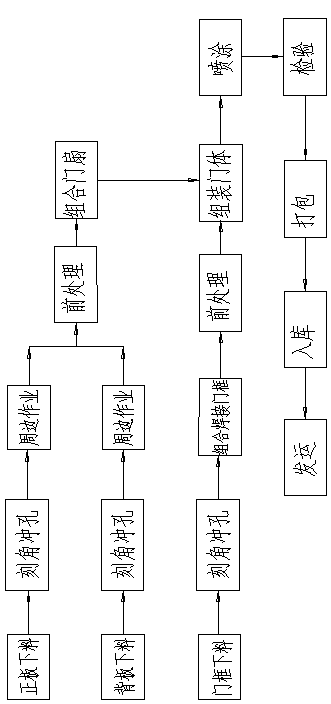

[0017] Such as figure 1 Shown, a kind of anti-theft door manufacturing new technology of the present invention comprises the following steps:

[0018] (1) According to the design drawings, use a shearing machine to cut the front panel, back panel and door frame respectively;

[0019] (2) Use the combined punching machine to punch the corners of the front panel, the back panel and the frame of the door frame respectively;

[0020] (3) Use peripheral machines to bend the front panel and back panel respectively; assemble and weld the entire door leaf; assemble and weld the frame into the door frame;

[0021] (4) Carry out pretreatment on the finished door leaf and door frame; the pretreatment consists of cleaning steps and phosphating solution steps;

[0022] (5) Use a heat sealing machine to assemble the door leaf and door frame into a complete door body;

[0023] (6) Spraying the surface of the door body; the spraying operation is spray paint or thermal spray powder;

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com