Nitrotoluene washing device and method

A technology of nitrotoluene and washing equipment, which is applied in the field of refinement, can solve the problems of large primary water consumption, difficult biochemical treatment, and difficult to pass the washing, so as to reduce the amount of waste water produced, reduce the amount of treated waste water, and achieve good washing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

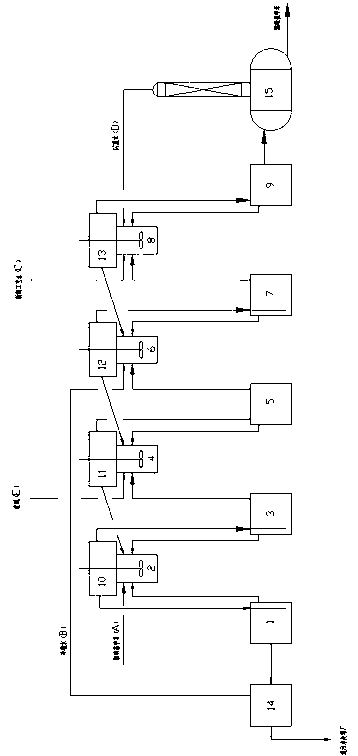

[0035] like figure 1 As shown, 100 parts of crude nitrotoluene A, 60 parts of fresh water C, 10% of the flash water B evaporated from the waste water, and all the flash water D are continuously added to the washing device and adjusted by the internal water circulation valve to make the washing kettle ( 2, 4, 6, 8) The volume ratio of the washing water to the crude nitrotoluene is 5:3, the neutralizer E is an aqueous sodium hydroxide solution with a mass concentration of 1%, and the amount of sodium hydroxide is neutralized to PH =9, the washing operation temperature is 30°C, and the washed nitrotoluene mixture enters separation and purification.

Embodiment 2

[0037] like figure 1 As shown, 100 parts of crude nitrotoluene A, 50 parts of fresh water C, 20% of the flash water volume B evaporated from the waste water is, and all the flash water D is continuously added to the washing device, adjusted by the internal water circulation valve, so that the washing tank The volume ratio of the washing water in (2, 4, 6, 8) to the crude product of nitrotoluene is 5:1, the neutralizer E is an aqueous sodium hydroxide solution with a mass concentration of 4%, and the amount of sodium hydroxide is neutralized to PH=10, washing operation temperature is 40°C, and the washed nitrotoluene mixture enters separation and purification.

Embodiment 3

[0039] like figure 1 As shown, 100 parts of crude nitrotoluene A, 40 parts of fresh water C, 30% of the flash water volume B evaporated from the waste water, and all the flash water D are continuously added to the washing device and adjusted by the internal water circulation valve to make the washing kettle ( 2, 4, 6, 8) The volume ratio of the washing water to the crude nitrotoluene is 5:2, the neutralizer E is an aqueous sodium hydroxide solution with a mass concentration of 7%, and the amount of sodium hydroxide is neutralized to PH =12, the washing operation temperature is 50°C, and the washed nitrotoluene mixture enters separation and purification.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com