Main part device of shaking force hydraulic engine

An engine and hydrodynamic technology, applied in the direction of machines/engines, mechanisms for generating mechanical power, mechanical equipment, etc., can solve problems such as rare discoveries, and achieve the effects of strong practicability, stable performance, and convenient manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

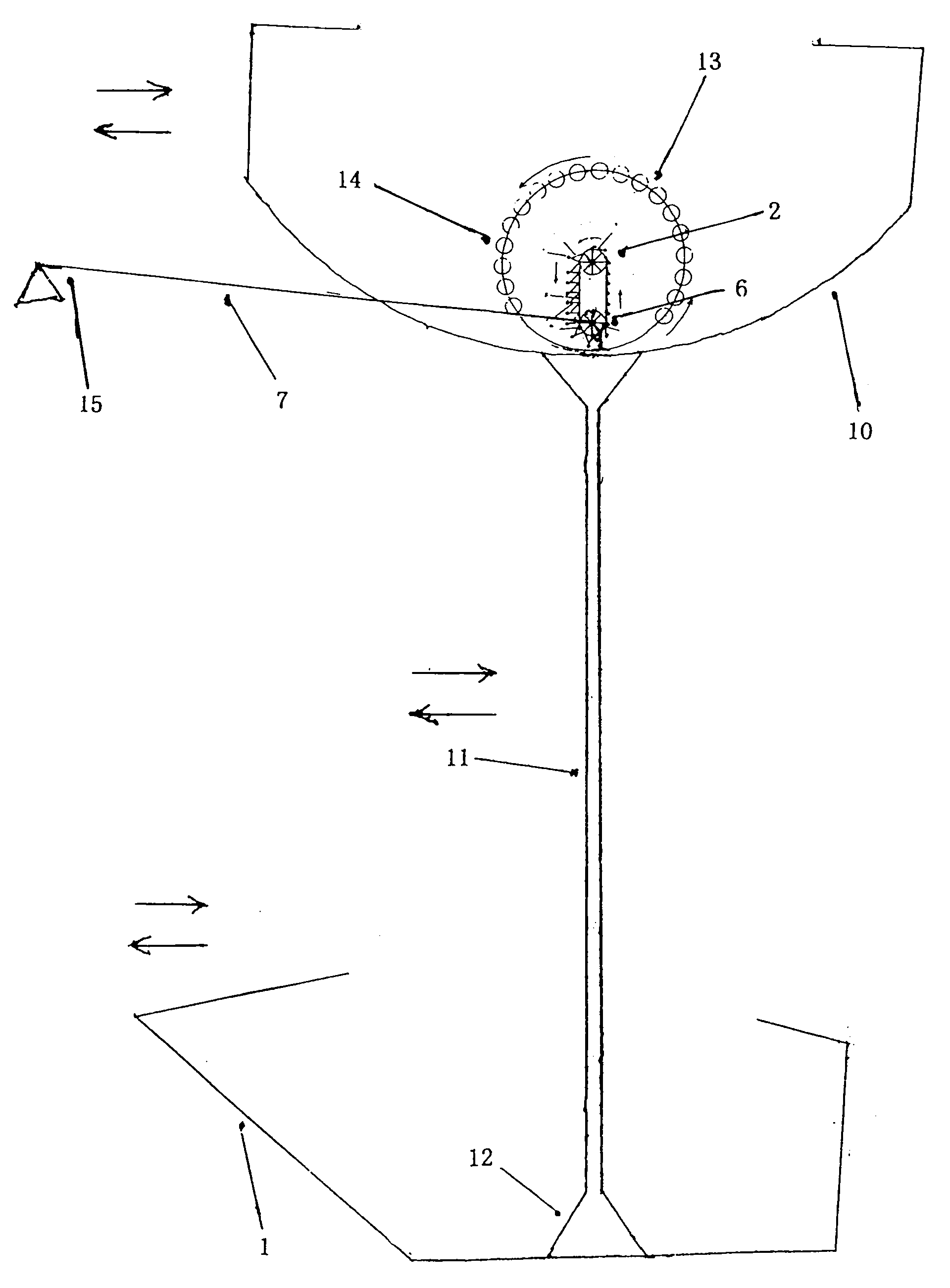

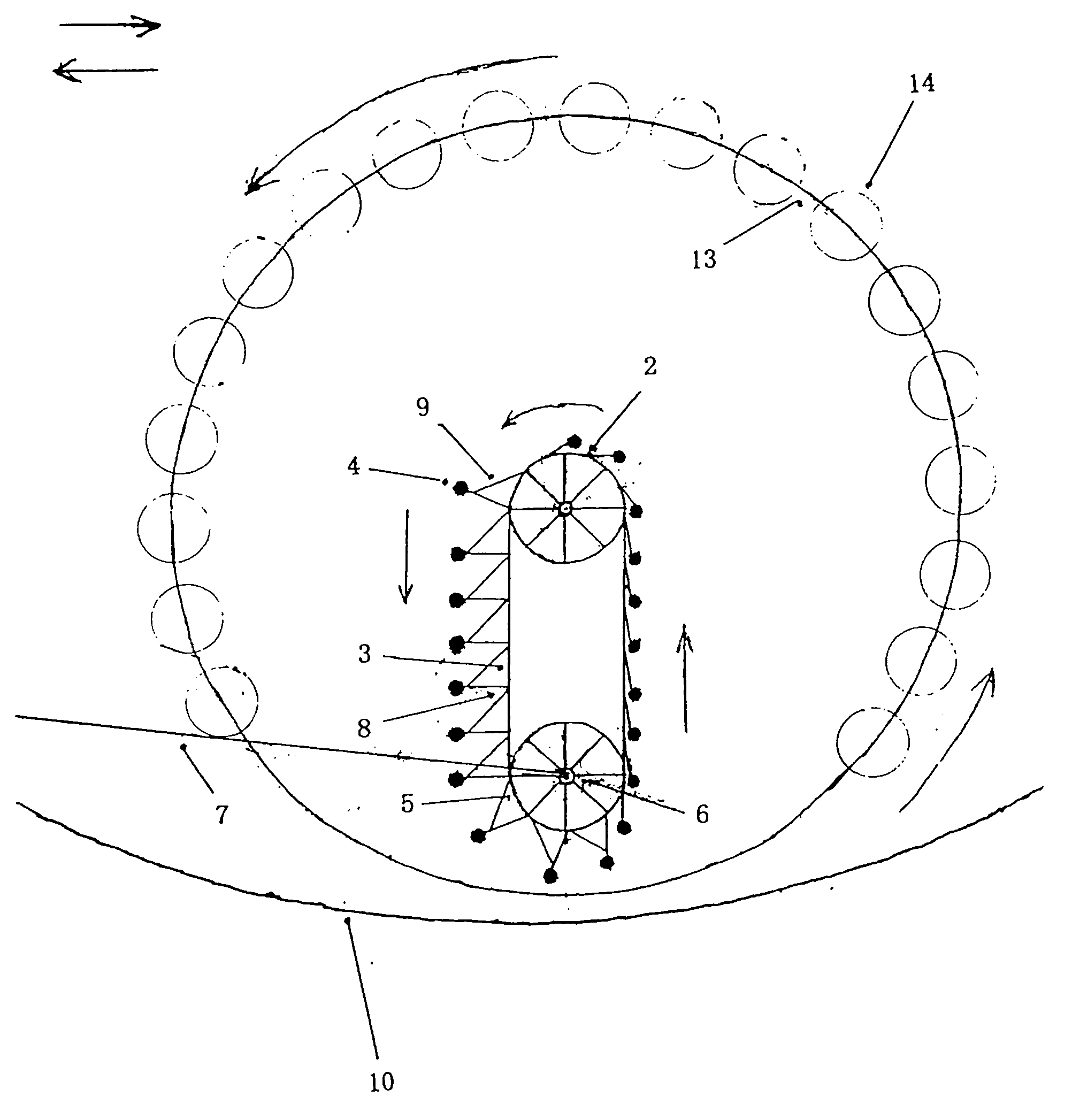

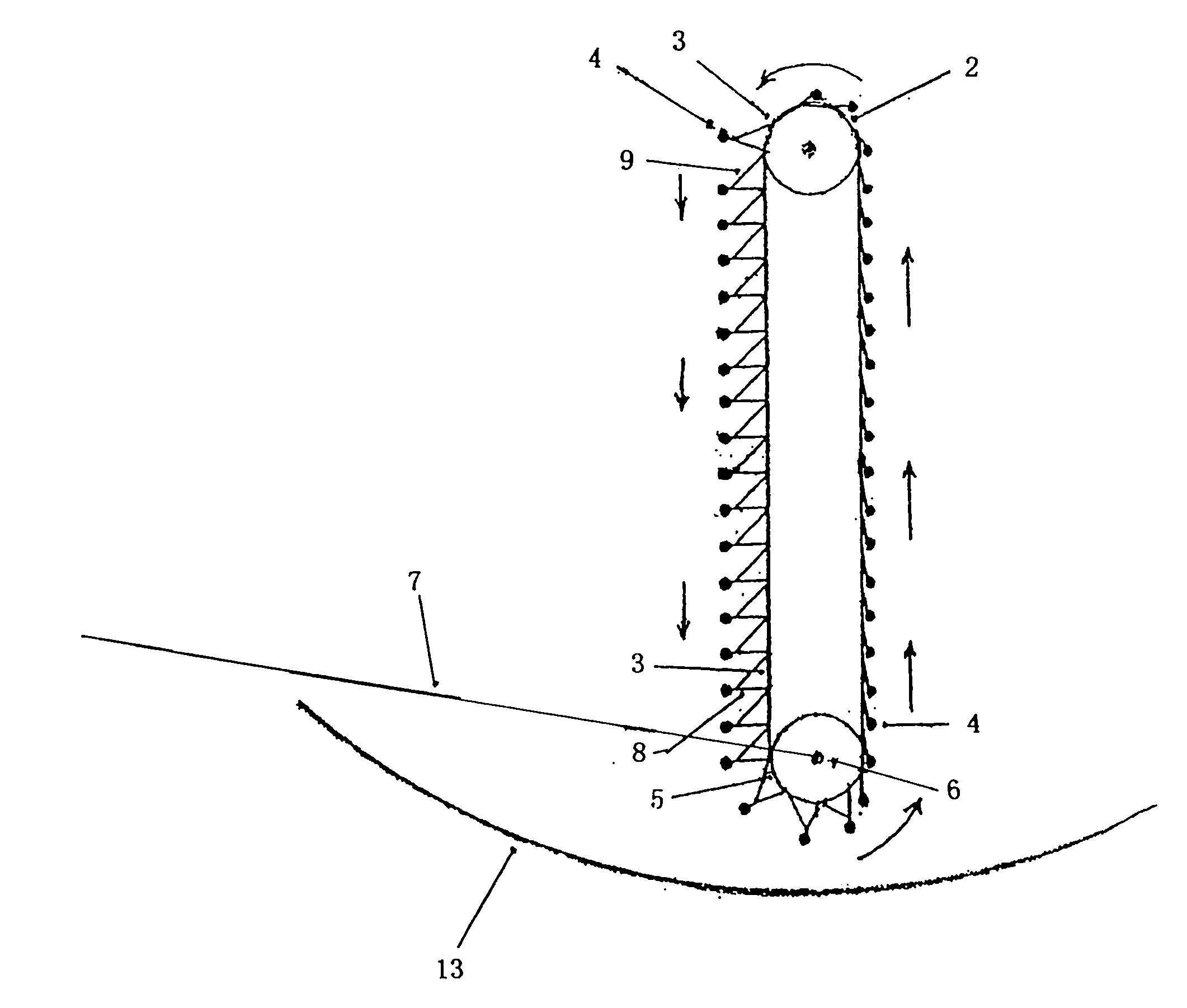

[0013] exist figure 1 Among them, the hull pile base (12) is set on the undulating pontoon (1) to connect, and the high-position elastic shaking long rod (11) is set on the hull pile base (12) to connect, and the high-position elastic shaking long rod (11) is connected to the elevated arc shaking The track is rotatable (10) connected, and the bull wheel (13) with many small bearings (14) is arranged on the elevated arc swing track (10), and the load wheel (2) is connected in the middle of the bull wheel (13). ), the middle of the pay piece wheel central axis (6) is connected with a section of superlong drag cable (7). The bull wheel (13) is connected with many small bearings (14) in rolling contact. Many small bearings (14) are connected with the rolling contact of the elevated arc swinging track (10), and superlong pull cables (7) are set on the anchor piles (15) to connect.

[0014] exist figure 2 middle, figure 2 and figure 1 The part is the same, many small bearings...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com