Air pump with improved air tightness

An improved, airtight technology, applied to components of pumping devices for elastic fluids, pump elements, variable displacement pump components, etc., can solve the problem of reducing the airtightness of air pumps, elastic fatigue, and head-shaped exhaust Problems such as tilting and deformation of the one-way valve can be avoided to avoid tilting and deformation, improve air tightness, and avoid deformation of the human head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

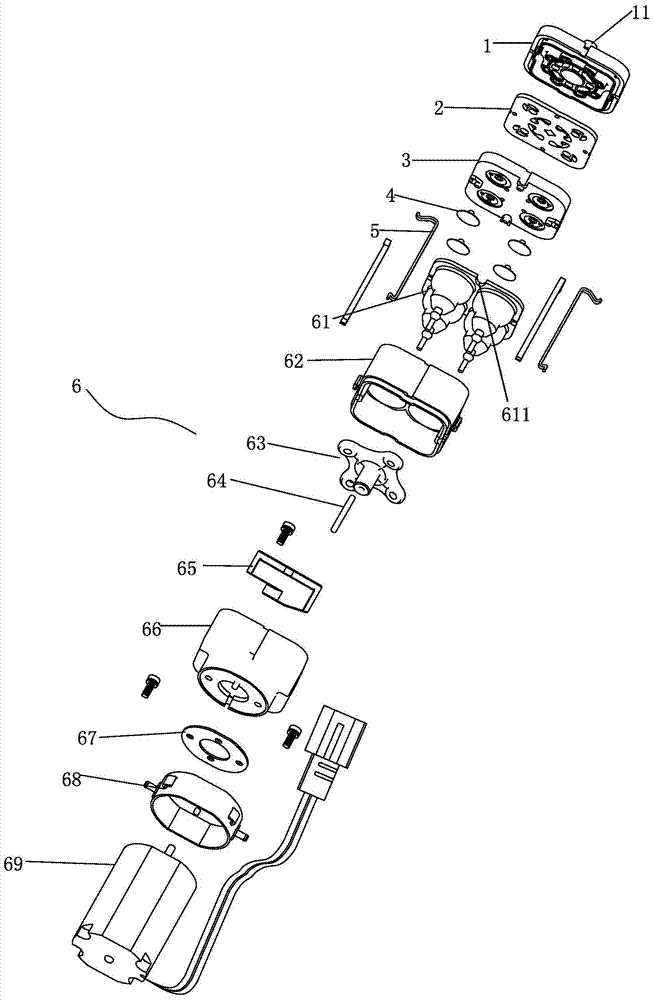

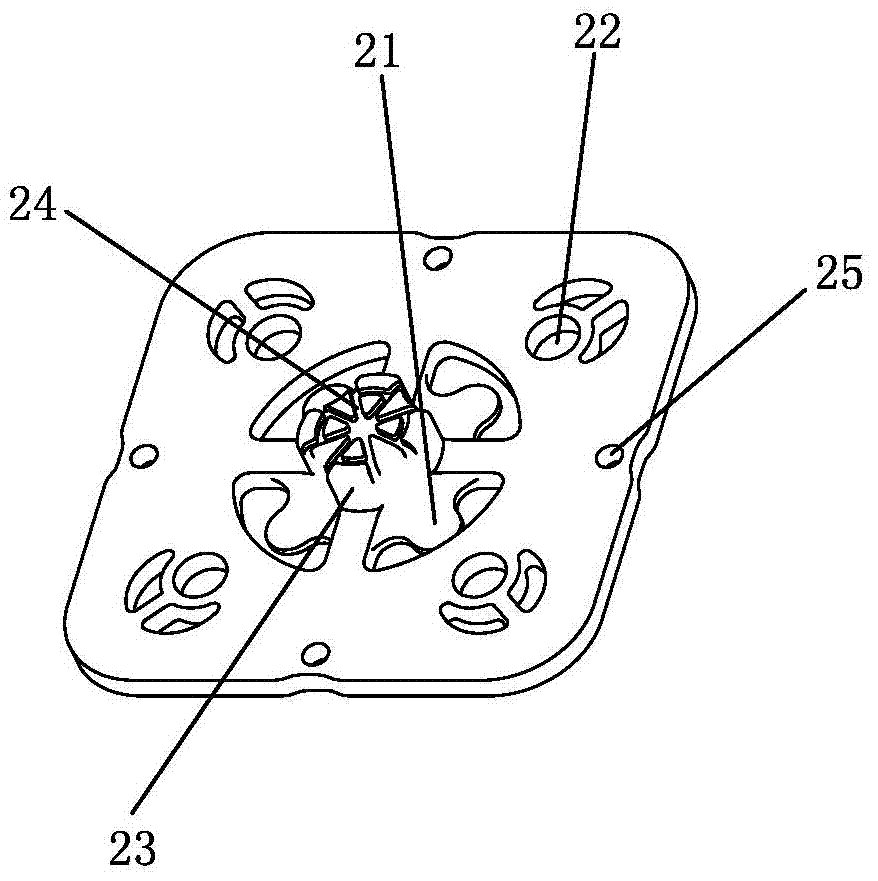

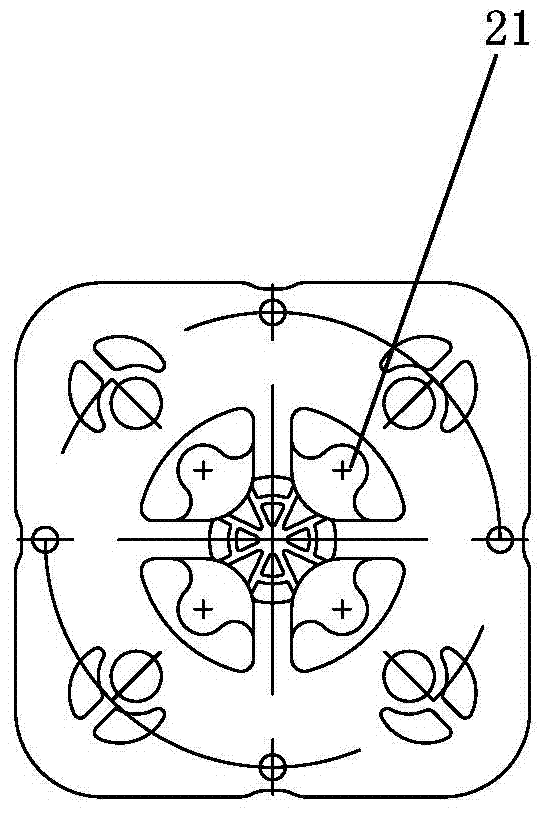

[0027] Embodiment, please refer to the accompanying drawings, a kind of airtightness improved air pump of the present invention, comprises the upper cover 1 that is provided with exhaust nozzle 11, gasket 2, human head shape exhaust one-way valve 21, distribution device and The piston assembly 6; the gasket 2 is provided with a first air inlet channel and a first air outlet channel 22, the gasket 2 is sealingly fitted to the bottom end of the upper cover 1, and forms an air inlet cavity and an air outlet separated from each other with the upper cover 1 Cavity, the first air intake passage 22 corresponds to the air intake chamber, the first air outlet passage corresponds to the air outlet chamber, and the air outlet chamber communicates with the exhaust nozzle 11 of the upper cover 1; the head-shaped exhaust one-way valve 21 is integrally connected on the lower surface of the first air outlet channel of the gasket 2, and the height of the top surface of the head-shaped exhaust c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com