Prismatic rod vacuum pump

A vacuum pump and prism technology, applied in the direction of pumps, pump components, rotary piston pumps, etc., can solve the problems of easy damage to piston rings and air valves, non-green environmental protection, high operation and maintenance costs, and improve the sealing effect. Lubrication effect, effect of increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

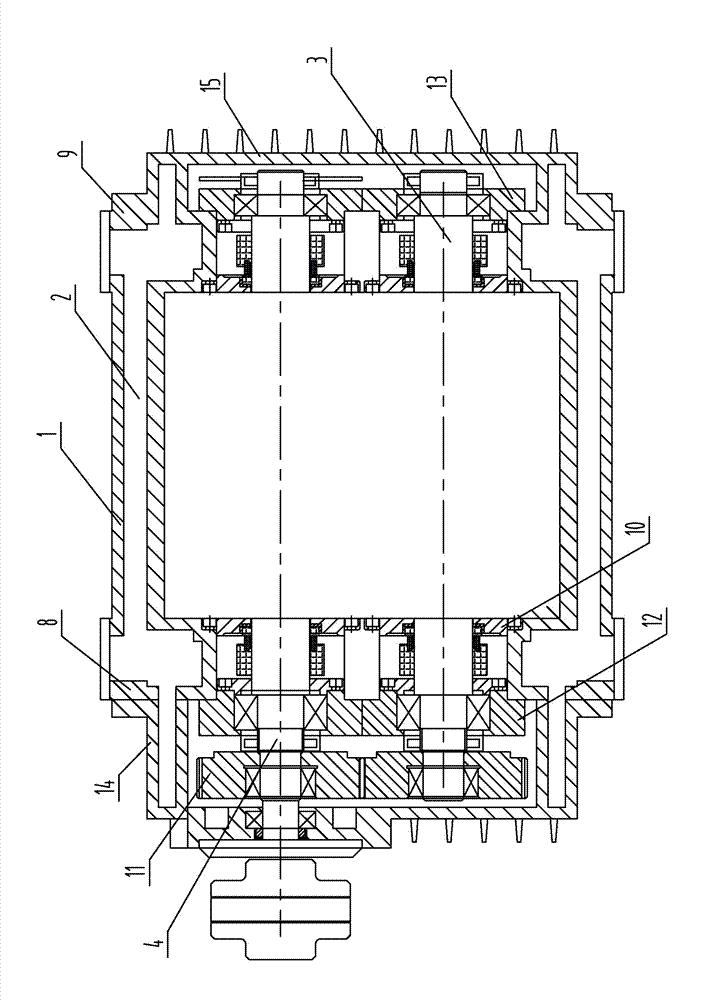

[0046] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0047] The present invention is named as a rib-rod vacuum pump because of its rotor with rib-rod structure.

[0048] In the present invention, the length direction of the rotor is defined as the front-rear direction, the side close to the pump cavity 7 is defined as the inner side, and the side far away from the pump cavity 7 is defined as the outer side accordingly.

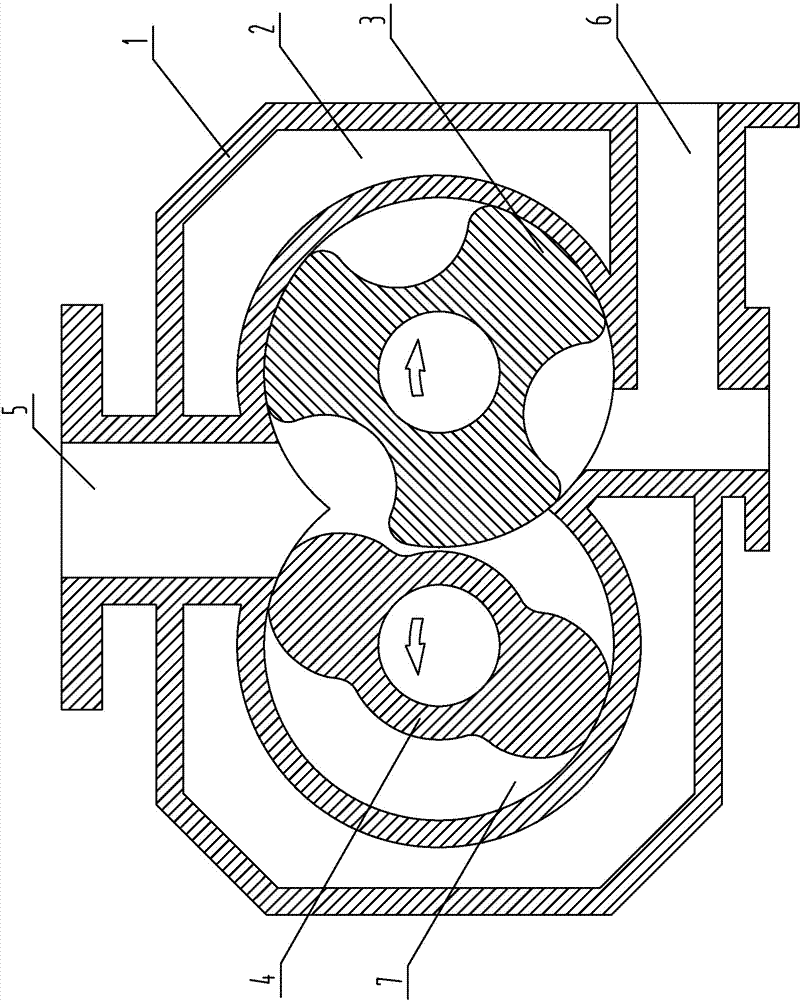

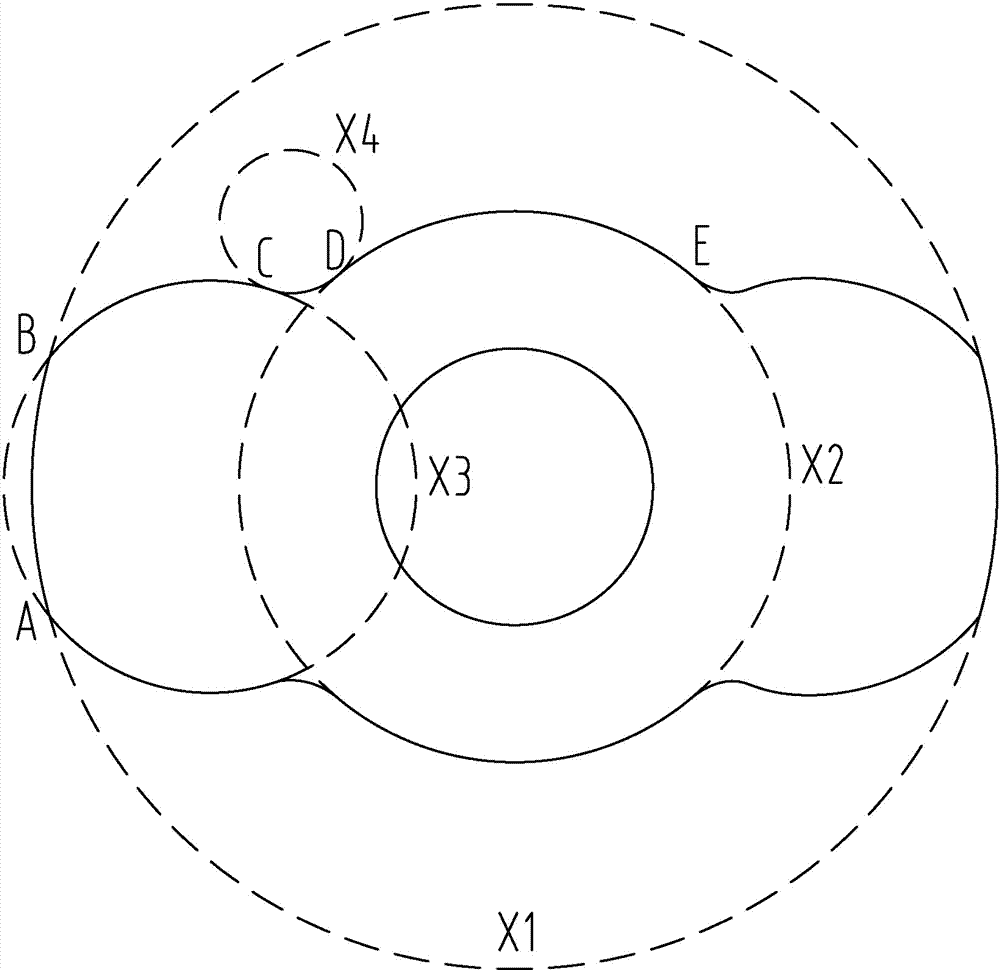

[0049] Such as figure 1 As shown, the pump casing 1 of the present invention is provided with a "∞" type pump chamber 7, and the rotor installed in the pump chamber 7 is divided into a main rotor 4 and an auxiliary rotor 3 whose axes are parallel to each other. The two convex teeth of the cloth, the profiles of the convex teeth are parallel to the axis of the main rotor 4, such as figure 2 As shown, the profile line of the end surface is a symmetrical structure, whic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com