Welding nut and method for connecting welding nut with objects

A technology for welding nuts and articles, applied in the direction of nuts, connecting members, threaded fasteners, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

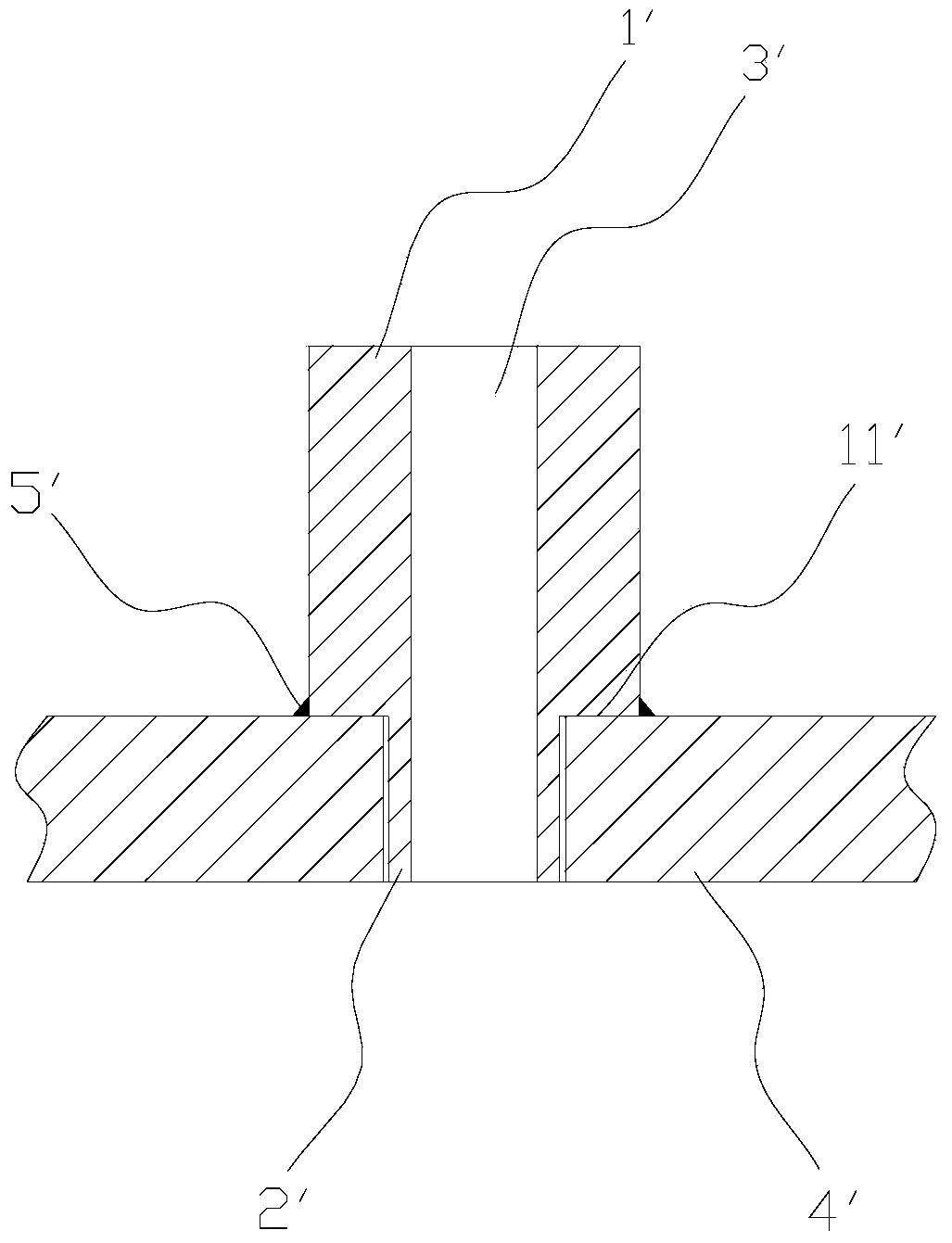

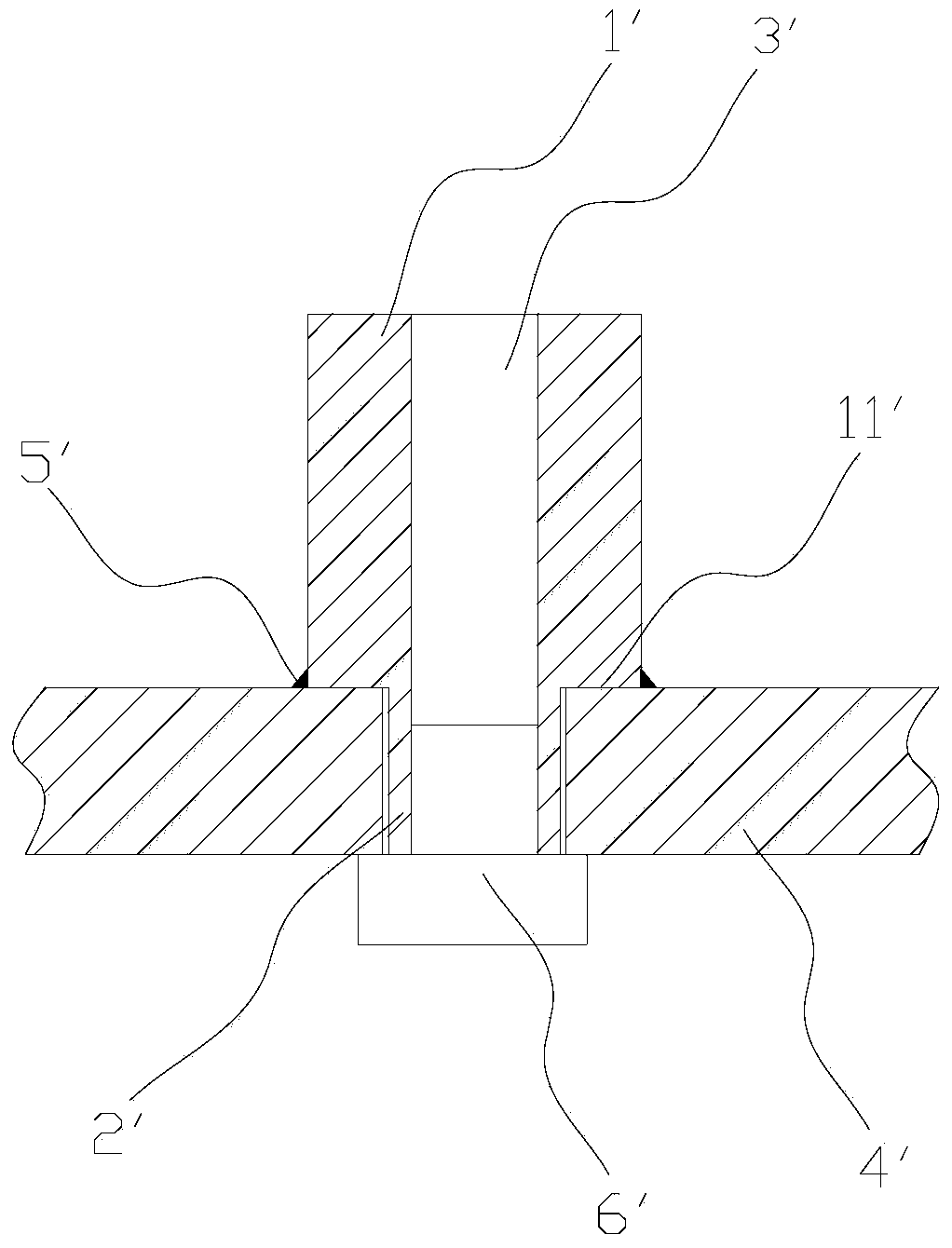

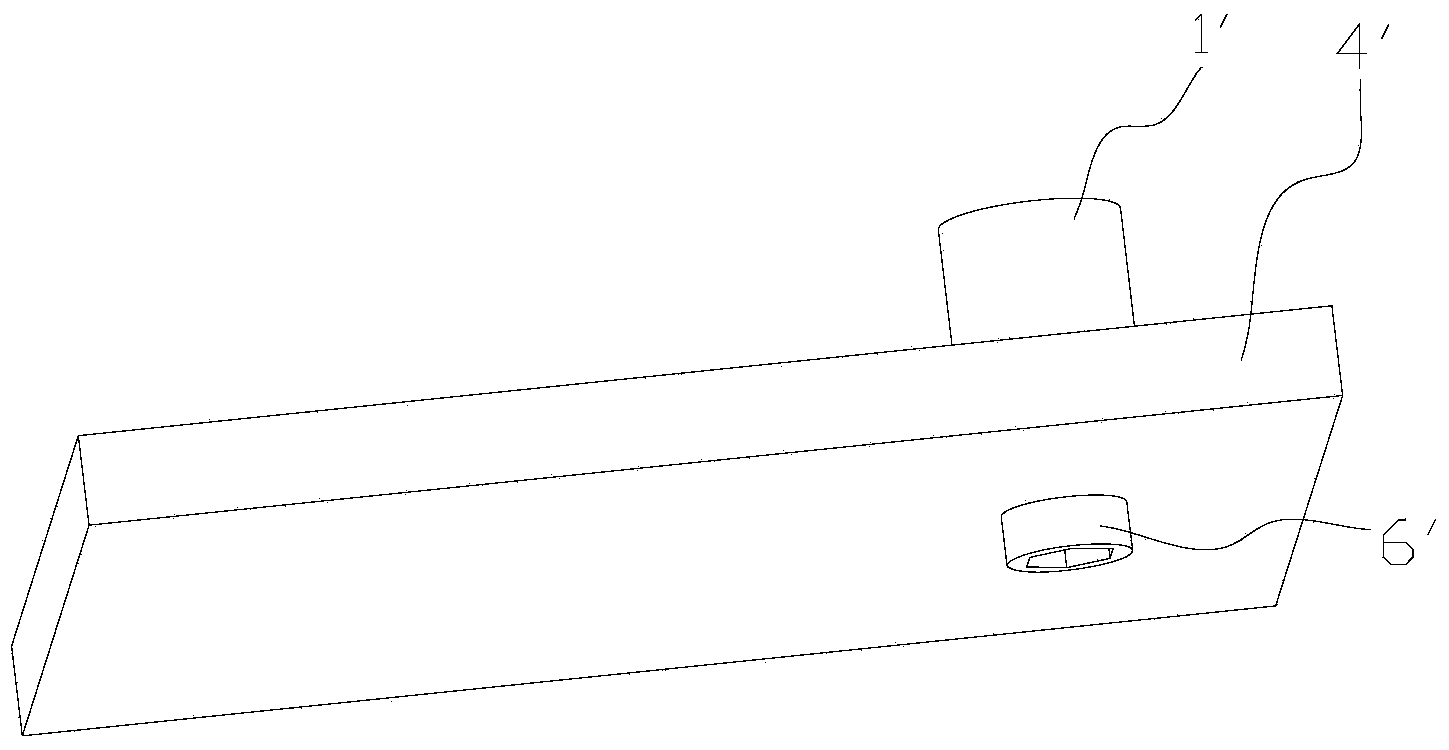

[0032] The technical solution in the embodiment will be specifically, clearly and completely described below in conjunction with the drawings in the embodiment.

[0033] see Figure 6 and Figure 7 As shown, a welding nut provided by the embodiment of the present invention includes a nut body 1 and an extension part 2 arranged coaxially. The extension part 2 is fixedly connected to one end of the nut body 1. The diameter of the extension part 2 is larger than that of the nut body 1. diameter, and at least the other end surface of the nut body 1 is provided with a threaded through hole 5 extending in the axial direction; the outer peripheral wall of the extension part 2 is provided with a plurality of flanges 3 arranged in a gear shape, and the flanges 3 are arranged in the axial direction Extension; an annular groove 4 is provided on the outer peripheral wall at one end of the nut body 1 , and one end of the flange 3 is in contact with the groove 4 .

[0034] Wherein, the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com