Motor-driven air storage and supply system

A technology of gas storage tank and gas outlet pipe, which is applied in mechanical equipment, container discharge method, equipment installed in pressure vessels, etc., can solve problems such as easy corrosion of the bottom, blockage of industrial processes, interruption of gas supply, etc., to expand the reserve capacity. , Reduce the degree of rust, the effect of gas buffering and smoothing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

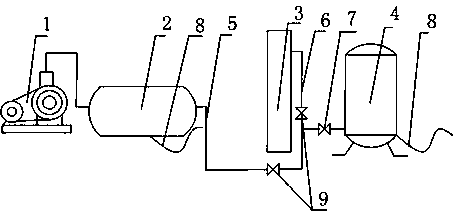

[0020] see figure 1 , a motor-driven gas storage gas supply system, including an air compressor 1, a first gas storage tank 2, a pressure storage device 3 and a second gas storage tank 4, the air compressor 1 and the first gas storage tank 2, the second gas outlet pipe 5 of the first gas storage tank 2 is connected to the air inlet of the second gas storage tank 4, and the third gas outlet pipe 6 of the pressure storage device 3 is connected to the air inlet of the second gas storage tank 4. The air inlet of the second gas storage tank 4 described above is connected.

[0021] The above-mentioned second air outlet pipe 5 and the third air outlet pipe 6 are provided with an on-off valve 9 , and a decompression valve 7 is provided at the junction of the second air outlet pipe 5 and the third air outlet pipe 6 .

[0022] The above-mentioned second gas storage tank 4 has a design pressure of 0.2-0.8mpa and a height of 1.5m-1.95m.

[0023] Both ends of the above-mentioned first g...

Embodiment 2

[0026] Similar to Embodiment 1, the difference is that the above-mentioned second gas storage tank 4 is more than two, and the bottom of the above-mentioned second gas storage tank 4 and the pressure storage device 3 are equipped with a drain pipe 8, and the first gas storage tank 2 and the second gas storage tank 3 are cylindrical tanks, the first gas storage tank 2 adopts a horizontal type, the second gas storage tank 4 is a three-dimensional type, and the volume of the first gas storage tank 2 is smaller than that of the second gas storage tank 4. The dual setting of the first gas storage tank 2 and the second gas storage tank 4 and the arrangement of several second gas storage tanks 4 can store surplus gas, which can not only increase the gas supply to meet the needs of the industry, but also provide unexpected benefits. Use it to meet your needs. The setting of the drainpipe 8 can make the condensed water inside the pressure storage device 3 and the second gas storage ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com