Elastic sealing sleeve device for floating tube sealing of air pre-heater

A technology of air preheater and sealing elasticity, which is applied in the direction of engine sealing, lighting and heating equipment, combustion methods, etc., which can solve the problems of high rigidity and unfavorable high temperature sealing of pipe holes, so as to eliminate the hidden danger of large area fire and improve safety Performance, the effect of improving elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

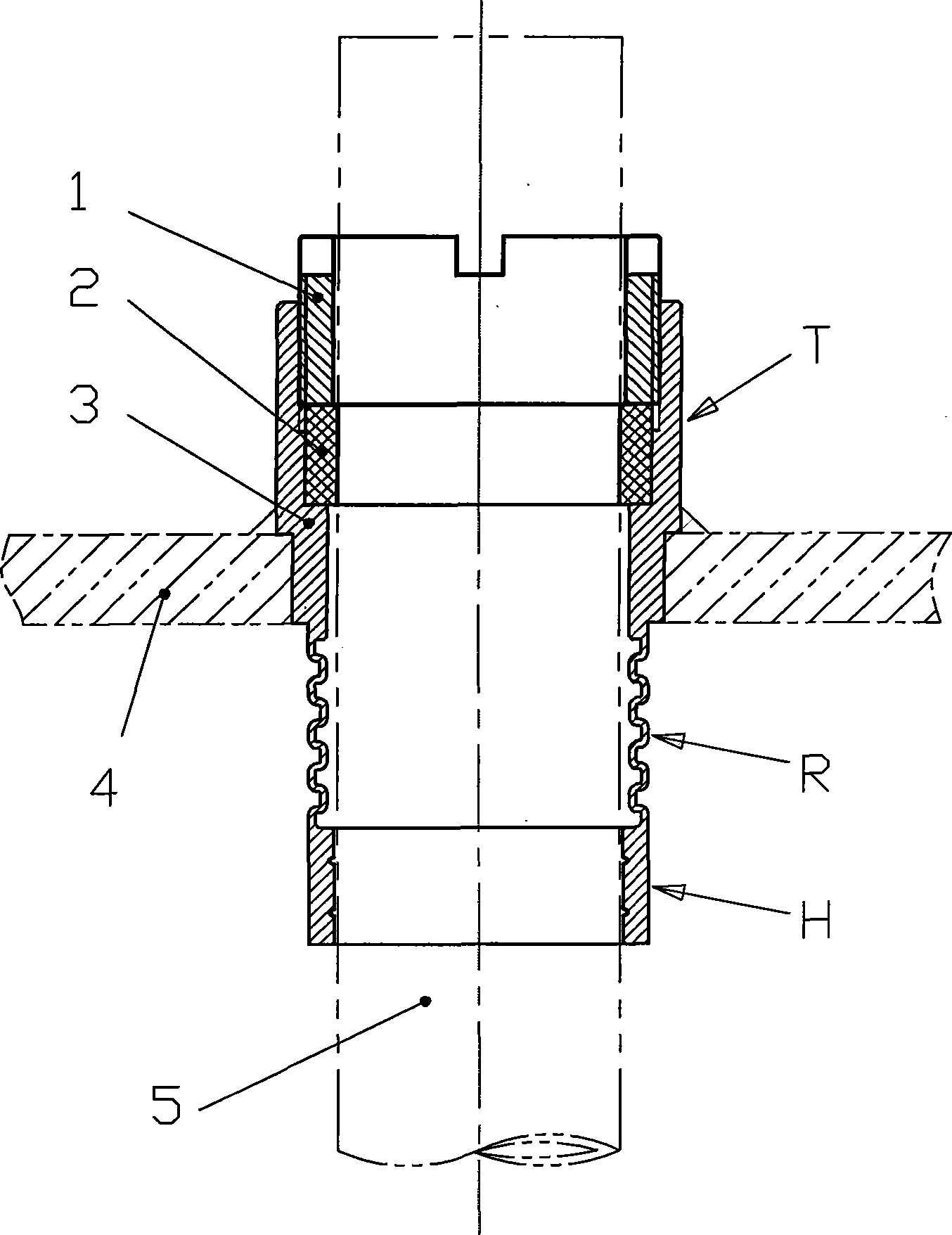

[0011] figure 1 In the middle, the elastic sealing sleeve (3) is welded to the tube sheet (4), the heat exchange tube (5) is put into the elastic sealing sleeve, the sealing packing (2) is put into the stuffing box, and the packing gland (1) is pressed. Tight, the tube hole can be sealed at room temperature.

[0012] figure 1 In the middle, the elastic sealing sleeve is divided into upper, middle and lower parts, among which the middle elastic cylinder (R) can be processed by the method of turning the inner and outer grooves on the lathe to process the corrugated section, or the "hydraulic multi-wave once Forming method" to produce a corrugated section to improve its elasticity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com