Manufacturing method of efficient solar heat collection device and efficient solar heat collection device product

A technology of solar heat collection and a production method, which is applied in the field of a production method of a high-efficiency solar heat collection device and the products produced by implementing the method, can solve the problems of low heat transfer efficiency, low anti-freezing performance, large heat dissipation loss and the like, Achieve the effect of high heat transfer efficiency, high energy utilization rate and fast heat collection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

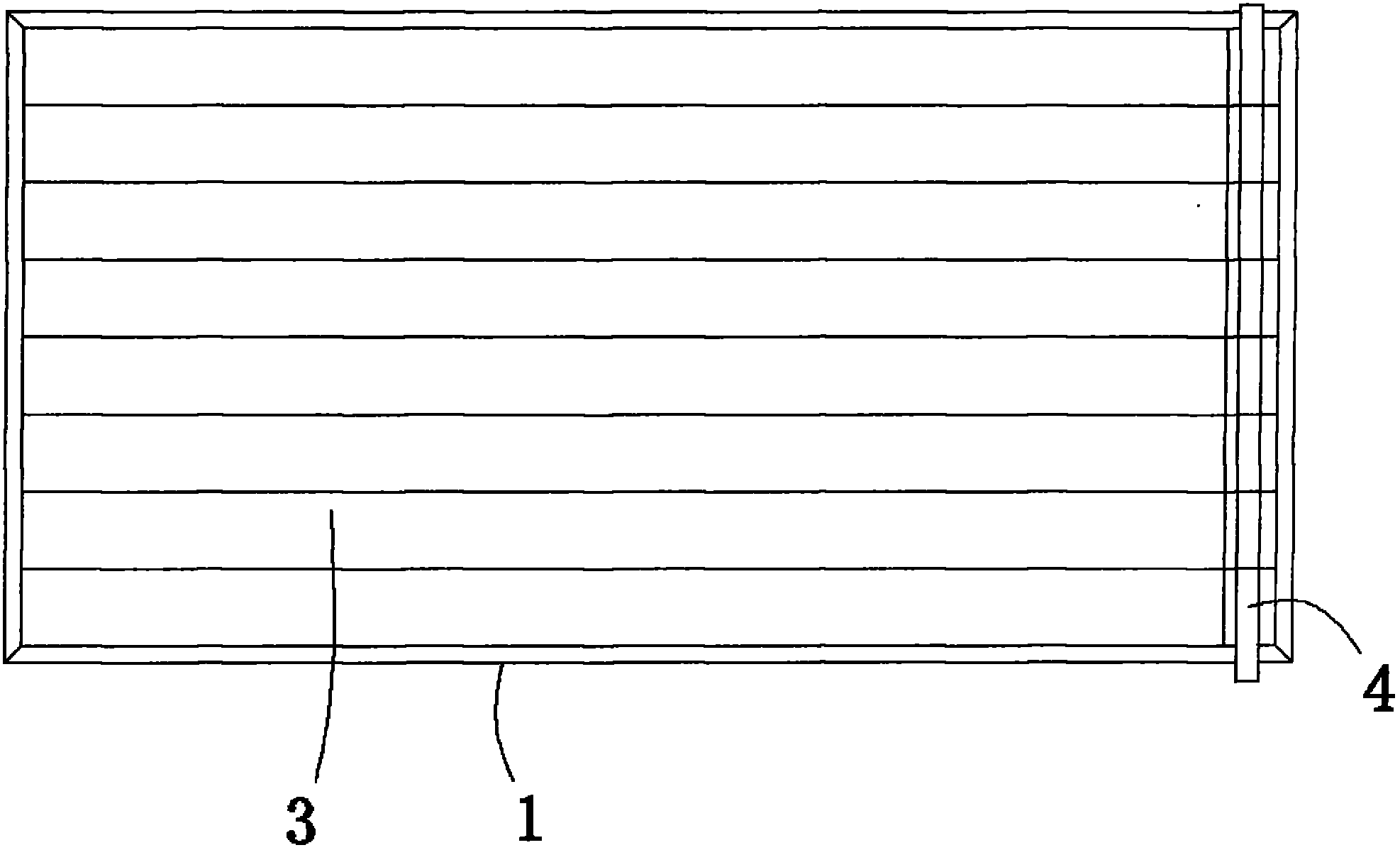

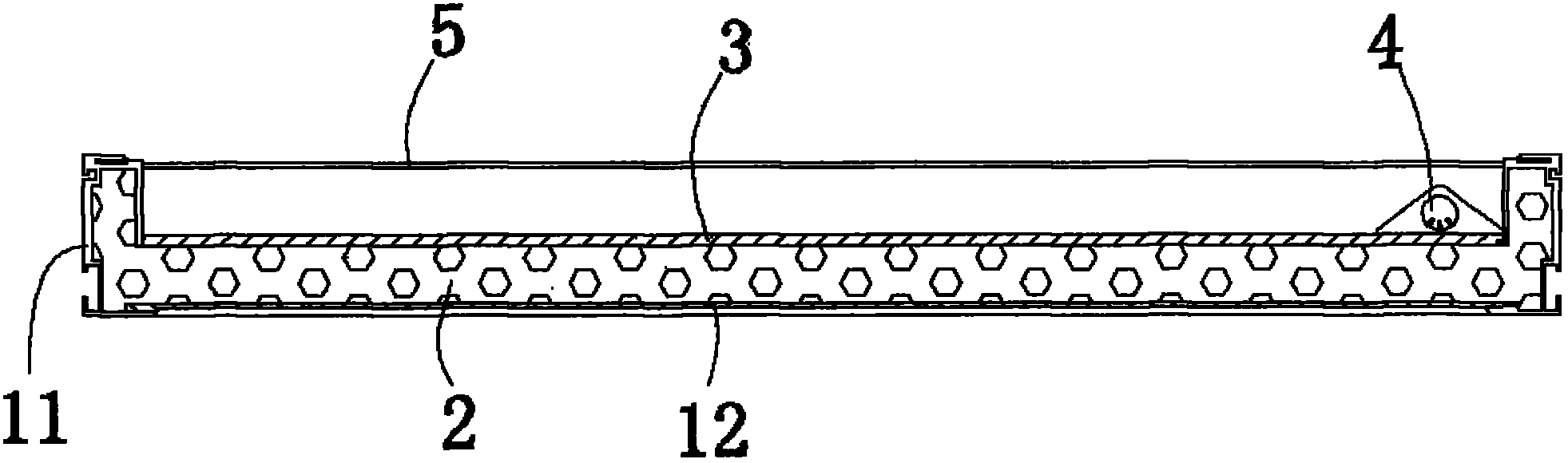

[0036] Embodiment 1: see Figures 1 to 3 , an embodiment of the present invention provides a method for manufacturing a high-efficiency solar heat collector, which includes the following steps:

[0037] (1) Make a plate-shaped box body 1, offer light incident window on the side wall of this box body 1;

[0038] (2) A heat insulating layer 2 is provided on the other side wall of the box body 1 opposite to the light incident window;

[0039] (3) Prepare several superconducting heat absorbing plates 3, and arrange the superconducting heat absorbing plates 3 in parallel in the box body 1;

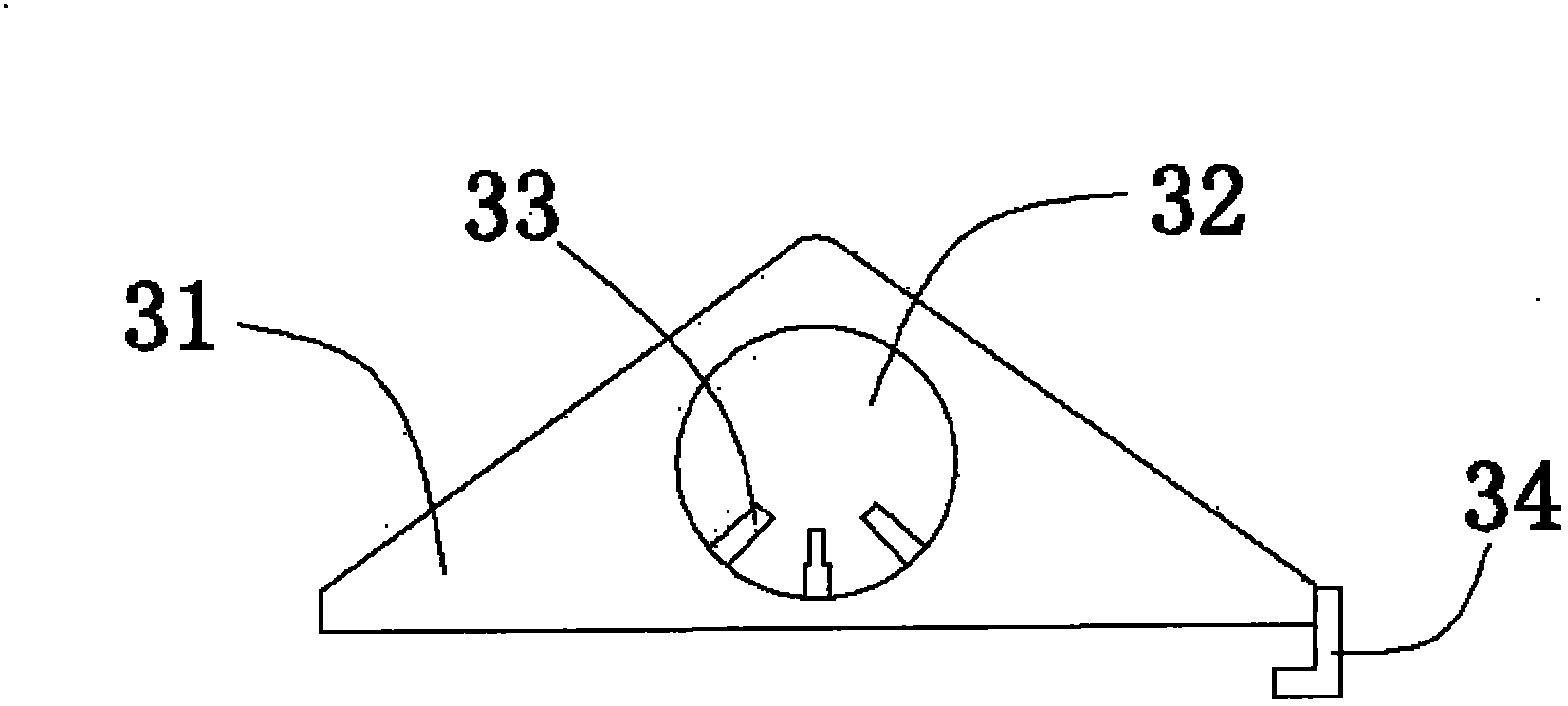

[0040] (4) make superconducting pipeline 4, each superconducting heat absorbing plate 3 is interconnected by this superconducting pipeline 4, and described superconducting pipeline 4 is made by the aluminum block 31 that isosceles triangular profile of a cross section, its A channel 32 is provided in the middle of the channel 32, and at least one heat conduction protrusion 33 is provided on t...

Embodiment 2

[0061] Embodiment 2, the embodiment of the present invention provides a product made by implementing the above-mentioned high-efficiency solar heat collection device manufacturing method, which is basically the same as embodiment 1, the difference is that the superconducting medium is a homogeneous mixture of the following weight percentages into:

[0062] Distilled water 90%,

[0063] Alcohol 4%,

[0064] Potassium permanganate 3%,

[0065] Trisodium Phosphate 2.5%,

Embodiment 3

[0067] Embodiment 3, the embodiment of the present invention provides a product made by implementing the above-mentioned high-efficiency solar heat collection device manufacturing method, which is basically the same as Embodiment 1, the difference is that the superconducting medium is a homogeneous mixture of the following weight percentages into:

[0068] Distilled water 78%,

[0069] Alcohol 10%,

[0070] Potassium permanganate 6%,

[0071] Trisodium Phosphate 5%,

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com