Method for repairing Maerz lime kiln suspension cylinder base

A repair method and technology for hanging cylinders, applied in the direction of lining repair, etc., can solve the problems of subsidence, damage, collapse of the whole kiln, etc. of the upper refractory bricks, and achieve the effects of long service life, strong heat resistance and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

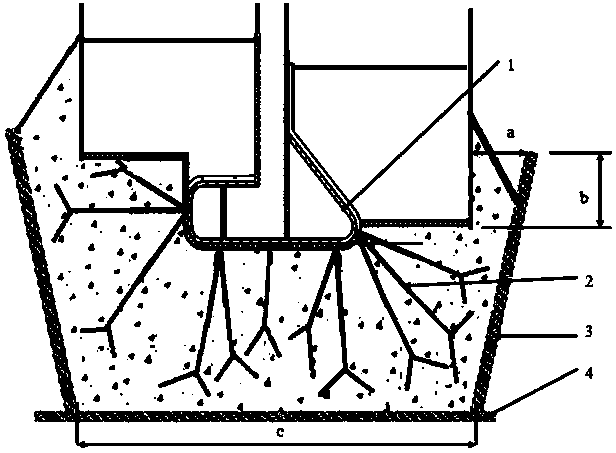

[0023] like figure 1 and figure 2 As shown, the Maerz lime kiln suspension cylinder base repair method is characterized in that it mainly includes the following steps:

[0024] (1), bandaging and heat insulation treatment

[0025] The suspended cylinder uses ceramic fiber paper and fiber blanket as the insulation layer, and glues the ceramic fiber paper and fiber blanket to the bottom 1 joint with glue paste, and the ceramic fiber paper is inside;

[0026] (2), welded anchor 2

[0027] An anchor 2 is welded at the steel plate skeleton at the bottom 1 of the suspension cylinder, the shape of the anchor 2 is "V", and the anchor 2 is welded by rebar, and the diameter of the rebar is Φ6.8mm;

[0028] (3), formwork support

[0029] The formwork adopts a hard wood board with a thickness of 10mm, the bottom form 4 is fixed on the anchor piece 2 with iron wire, the lower part of the side formwork 3 rests on the bottom formwork 4, and the upper part of the side formwork 3 slopes o...

Embodiment 2

[0037] like figure 1 and figure 2 As shown, the Maerz lime kiln suspension cylinder base repair method is characterized in that it mainly includes the following steps:

[0038] (1), bandaging and heat insulation treatment

[0039] The suspended cylinder uses ceramic fiber paper and fiber blanket as the insulation layer, and glues the ceramic fiber paper and fiber blanket to the bottom 1 joint with glue paste, and the ceramic fiber paper is inside;

[0040] (2), welding anchor

[0041] An anchor 2 is welded at the steel plate skeleton at the bottom 1 of the suspension cylinder, the shape of the anchor 2 is "V", and the anchor 2 is welded by rebar, and the diameter of the rebar is Φ8mm;

[0042] (3), formwork support

[0043] The formwork adopts a hard wood board with a thickness of 12mm, the bottom mold 4 is fixed on the anchor piece 2 with iron wires, the lower part of the side mold 3 rests on the bottom mold 4, and the upper part of the side mold 3 is inclined outwards a...

Embodiment 3

[0051] like figure 1 and figure 2 As shown, the Maerz lime kiln suspension cylinder base repair method is characterized in that it mainly includes the following steps:

[0052] (1), bandaging and heat insulation treatment

[0053] The suspended cylinder uses ceramic fiber paper and fiber blanket as the insulation layer, and glues the ceramic fiber paper and fiber blanket to the bottom 1 joint with glue paste, and the ceramic fiber paper is inside;

[0054] (2), welding anchor

[0055] An anchor 2 is welded at the steel plate skeleton at the bottom 1 of the suspension cylinder, the shape of the anchor 2 is "V", and the anchor 2 is welded by rebar, and the diameter of the rebar is Φ7mm;

[0056] (3), formwork support

[0057] The template adopts a hard wood board with a thickness of 11mm, the bottom mold 4 is fixed on the anchor piece 2 with iron wires, the lower part of the side mold 3 rests on the bottom mold 4, and the upper part of the side mold 3 is inclined outwards a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com