Quick cleaning equipment and cleaning method for large heat exchanger

A heat exchanger, fast technology, applied in the direction of cleaning heat transfer devices, lighting and heating equipment, washing, etc., can solve the problems of unreachable effect, metal corrosion, and unsatisfactory effect, etc., and achieve easy portability and fast cleaning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

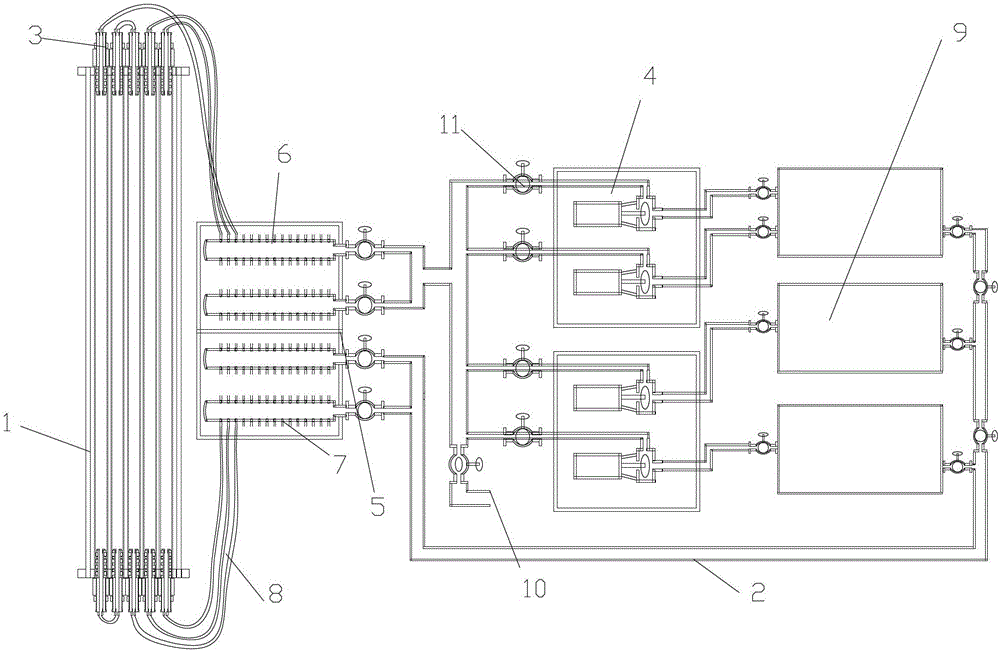

[0042] Such as figure 1, a large-scale heat exchanger quick cleaning equipment, including a shell and tube heat exchanger 1, which can also be a U-shaped heat exchanger or a power plant condenser in specific implementation, without limitation; also includes a cleaning system 2 and several quick sealing A connector 3, the quick seal connector 3 is flexibly connected to the heat exchanger, the cleaning system is connected to the quick seal connector through a connecting pipe 8; the cleaning system at least includes a sub-control system 5: liquid supply sub-control subsystem 6 and liquid return sub-control sub-system 7, the liquid supply sub-control sub-system transports the liquid to one end of the heat exchanger through the quick seal joint, and after entering the heat exchanger, passes through the other end of the heat exchanger The quick seal connector returns the liquid to the liquid return sub-control subsystem, and the circulating liquid achieves the effect of cleaning the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com