Detecting tool for detecting rocker arm motion avoiding plane of irregular cavity of cylinder cover

A technology of cylinder head and plane, which is applied in the field of inspection tools for inspecting irregular-shaped cavities of cylinder head, can solve the problems of high equipment cost, affecting production efficiency, and long inspection time, so as to reduce the control of process links, reduce the difficulty of inspection operation, The effect of low professional skill requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with the accompanying drawings.

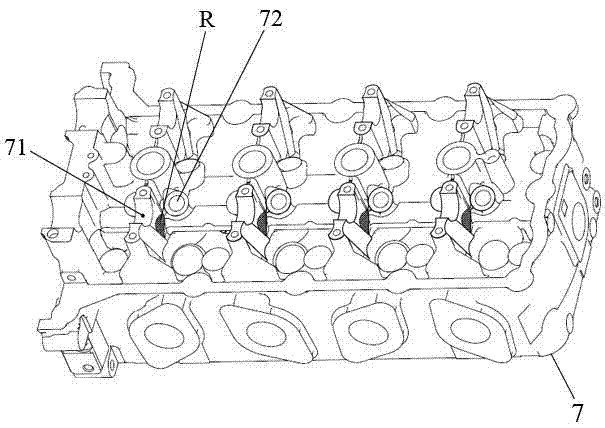

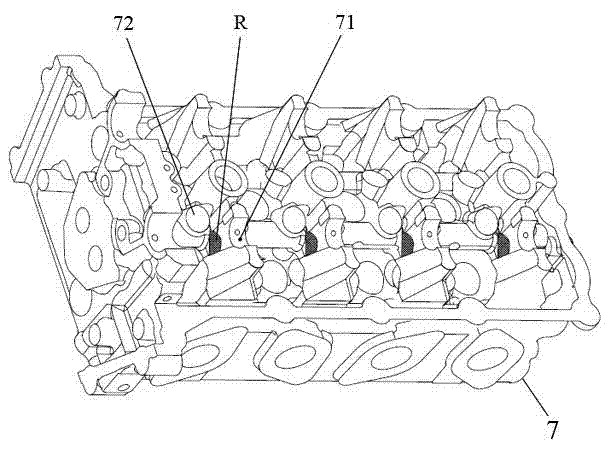

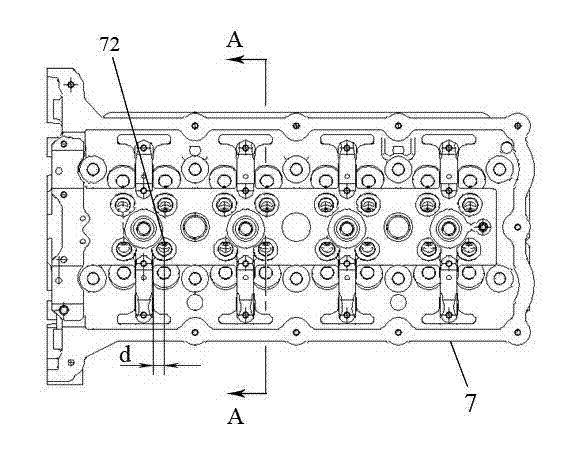

[0053] like Figure 1 to Figure 11 As shown, the inspection tool for detecting the rocker movement avoidance plane of the special-shaped cavity of the cylinder head according to the present invention includes a detection block 1 and a positioning mandrel 2, and the detection block 1 is fixedly connected to the upper part of the positioning mandrel 2, so that The detection block 1 is a right-angled trapezoidal body, which is used to detect the rocker movement avoidance plane R milled out on the cylinder head. It has six surfaces, which are two trapezoidal surfaces (the first trapezoidal surface A1, the second trapezoidal surface A2), the upper bottom surface A3, the lower bottom surface A4, the straight waist surface A5 and the inclined waist surface A6, the straight waist surface A5 is used as the limit reference plane, the inclined waist surface A6 is used as the dept...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com