A welding detection system and method for circuit board with cpu

A circuit board and virtual soldering technology, which is applied in the system field of detecting whether there are soldering faults on the circuit board and whether there is a problem with the chip, can solve the problems that the circuit board cannot be used, the difficulty of troubleshooting, and the pins are not visible, etc., to achieve convenience Repair, reduce the difficulty of detection operation, and have a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

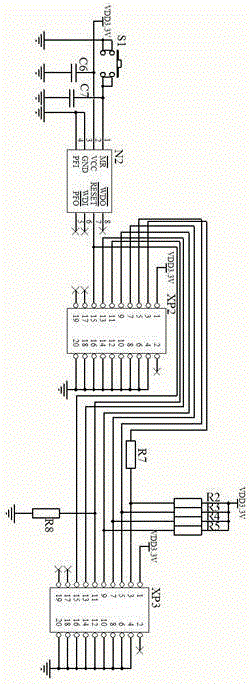

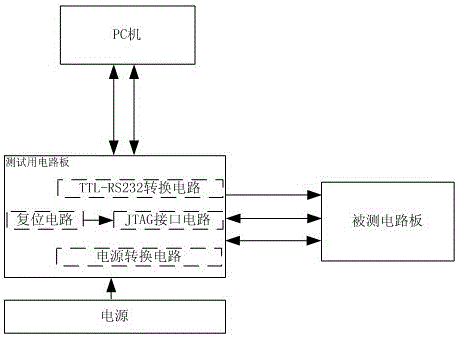

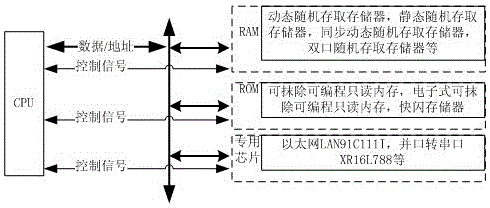

[0037] In order to understand the present invention more clearly, below in conjunction with accompanying drawing and embodiment describe in detail: as figure 1 As shown, a welding inspection system for a circuit board with a CPU includes a PC equipped with debugging software, a circuit board for testing and a power supply, and the circuit board for testing includes a TTL-RS232 conversion circuit, a reset circuit, a JTAG interface circuit and a power supply The conversion circuit, wherein the reset circuit is connected to the JTAG interface circuit, the test circuit board is connected to the PC and the circuit board under test through the TTL-RS232 conversion circuit and the JTAG interface circuit respectively, and the power supply is connected to the circuit board under test through the power conversion circuit.

[0038] The test circuit board is the intermediate hub for the system to test the short connection or false welding of the data line and address line. The functions ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com