Oil level monitoring method and monitoring system of an oil-immersed transformer oil storage system

An oil-immersed transformer and oil storage system technology, which is applied in the direction of displaying a liquid level indicator through pressure measurement, can solve the problem that the oil level accuracy requirements of the oil-immersed transformer cannot be met, and the oil level value of the oil storage system cannot be accurately obtained. Inability to provide accurate oil level data and other problems to achieve the effect of improving the scope of application, good control, good preservation and analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

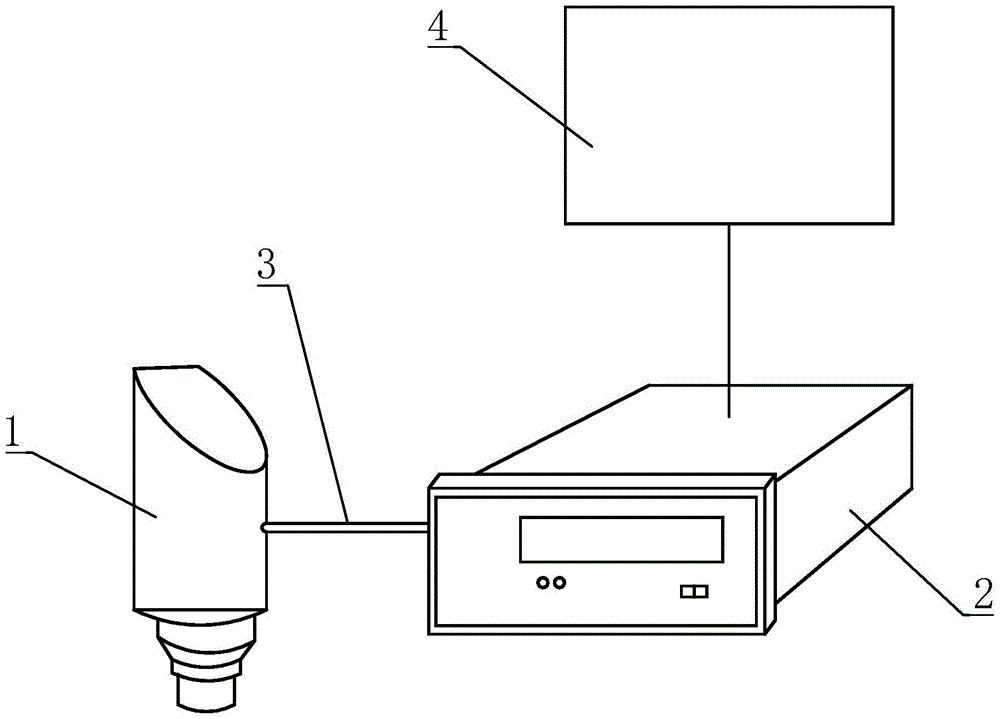

[0039] The present invention is an oil level monitoring system of an oil-immersed transformer oil storage system, such as figure 1 As shown, it includes a pressure sensor 1 set on the transformer, and a monitoring terminal 2 connected to the output of the pressure sensor 1; the monitoring terminal 2 is used to convert the pressure signal collected by the pressure sensor 1 into an oil level signal, and at the same time The oil level signal and pressure signal are monitored, and when the oil level signal or pressure signal exceeds a safe value, the monitoring terminal 2 sends out an alarm.

[0040] Preferably, the output end of the monitoring terminal 2 is connected to the host computer 4 for recording and analyzing the oil level signal output by the monitoring terminal 2; the connection line b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com