Turbocharger regulator spring thermal fatigue endurance test bench

A turbocharger and durability test technology, which is applied in the testing of machine/structural components, instruments, and mechanical components, etc. It can solve the problems of complex structure, high cost and complicated operation of the thermal fatigue durability test bench. The effect of advanced structure, simple operation and low test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

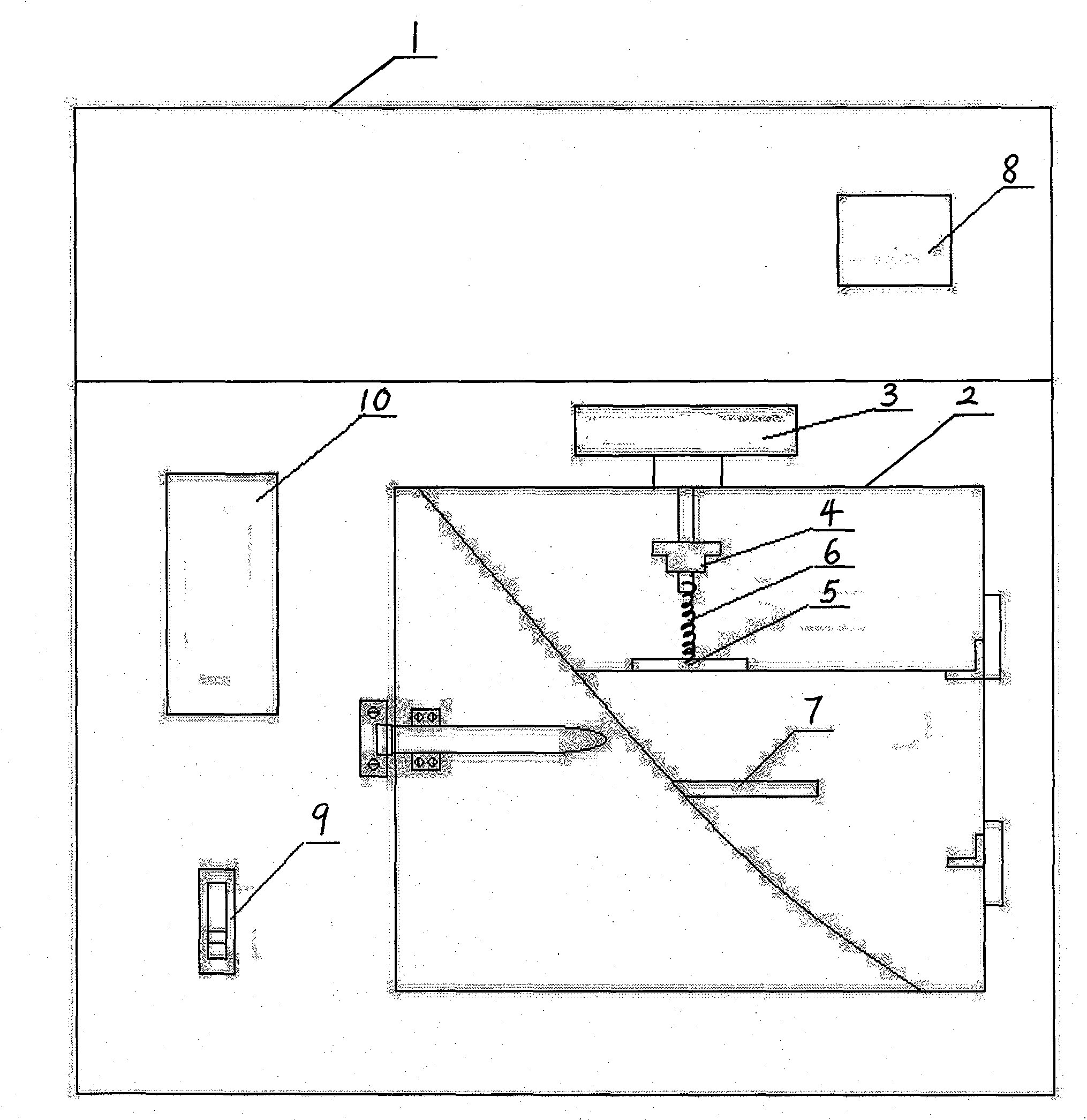

[0008] Turbocharger regulator spring thermal fatigue durability test bench, including housing 1, drying box 2, motor 3 and spring clamp, motor 3 is fixed on the upper part of housing 1, spring clamp is composed of cam 4 and fixed plate 5, cam 4 Installed on the power output shaft of the motor 3, the fixed plate 5 is fixed in the drying box 2, located below the cam 4, the experimental spring 6 is connected between the cam 4 and the fixed plate 5, and the drying box 2 is set in the shell 1 , The drying box 2 is equipped with a temperature-sensing rod 7, and the shell 1 is equipped with a counter 8, a drying box switch 9 and a temperature indicating regulator 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com