Site detection equipment for mechanical property of steel bars

A technology of on-site inspection and reinforcement mechanics, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of uncontrollability, waste of resources, length of reinforcement bars, etc., and achieve the effect of simple structure, convenient assembly, and quality assurance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

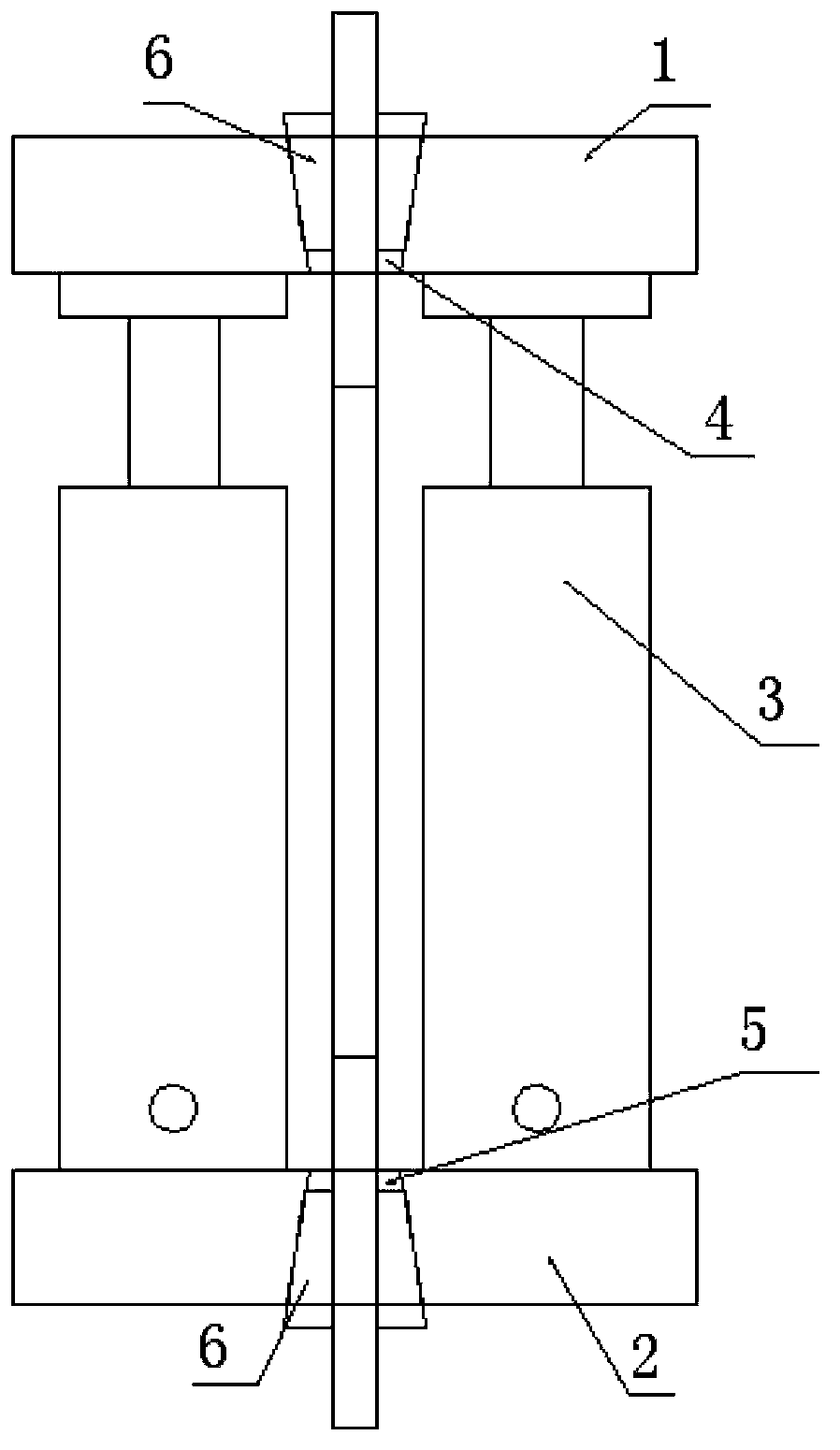

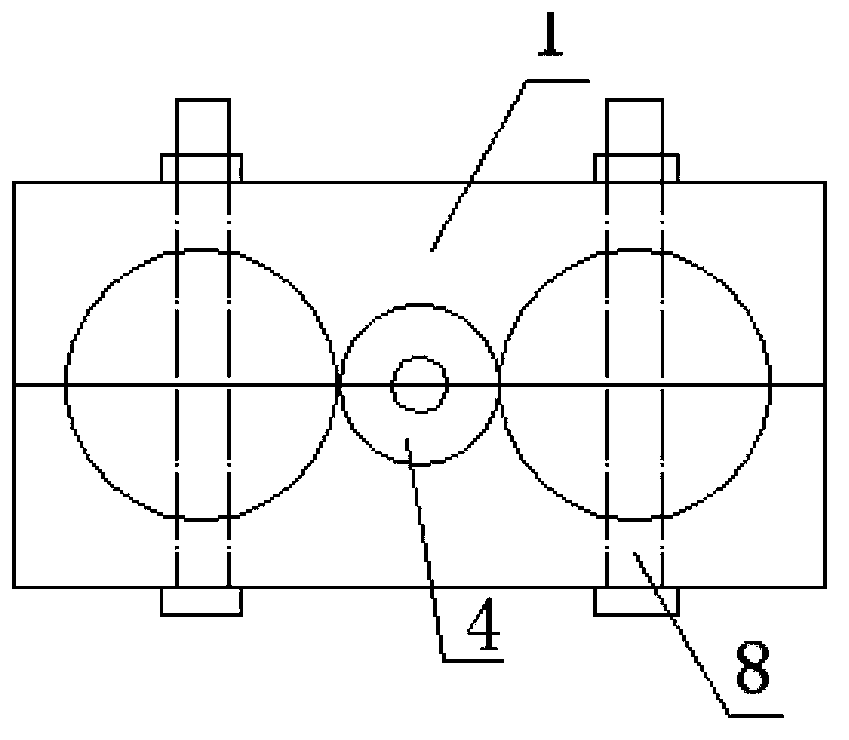

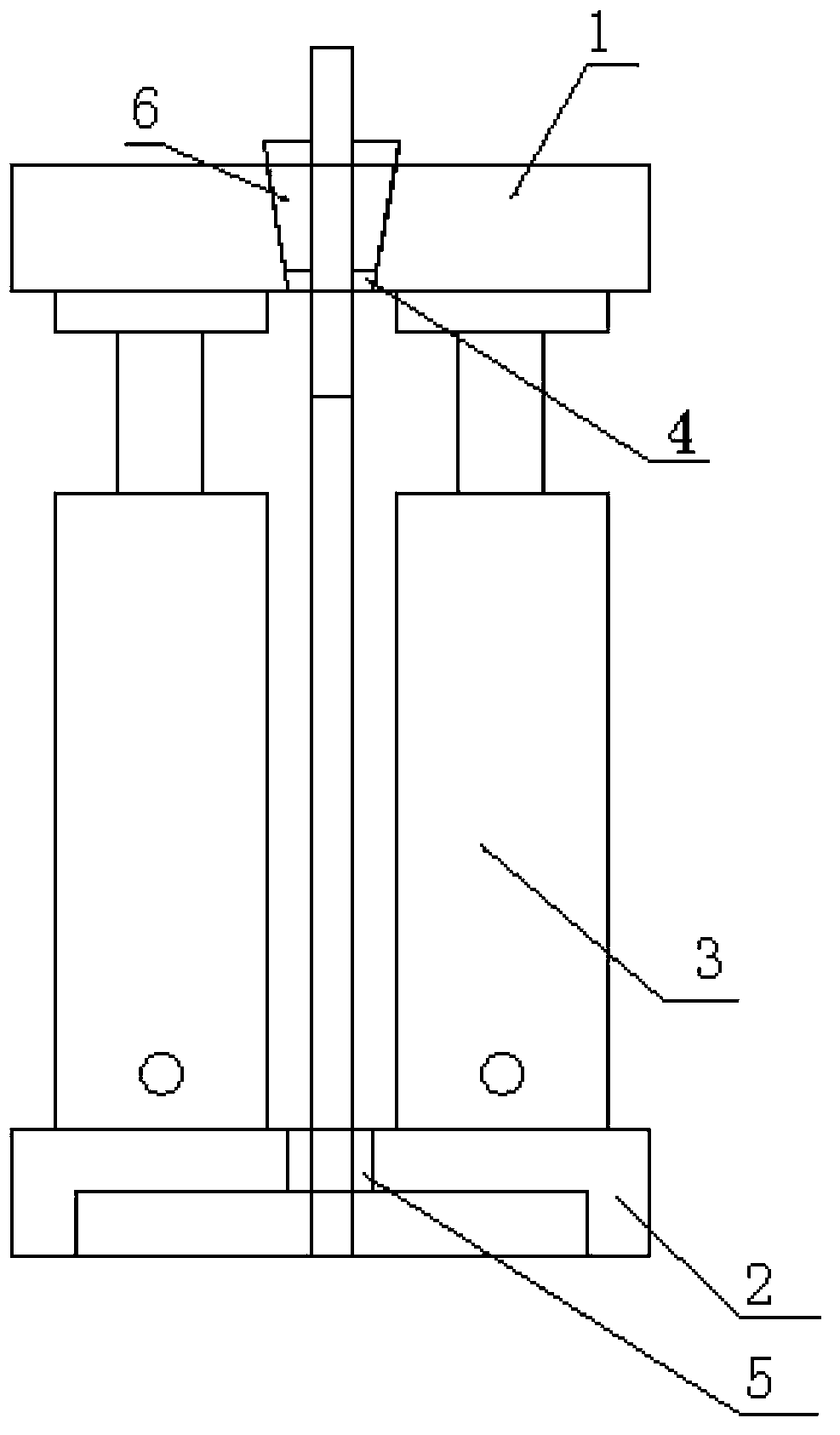

[0019] Embodiment: An on-site detection device for the mechanical properties of steel bars, including a fixture 1, a base 2 and a support device 3, the fixture 1 and the base 2 are respectively provided with coaxial first and second mounting holes 4, 5, and the first The interior of at least one of the first and second mounting holes 4 and 5 is provided with a steel bar fixing and clamping device 6, and the support device 3 can drive the clamp 1 to move relative to the base 2 along the axial direction of the first and second mounting holes 4 and 5. , first put the steel bars in the first and second installation holes 4, 5 of the fixture 1 and the base 2 and fix them through the steel bar fixing and clamping device 6 (for the steel bars in the anchored state, the second installation holes on the base 2 The steel bar fixing and clamping device 6 may not be used inside, the steel bar only needs to pass through the second installation hole on the base 2, and the steel bar fixing an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com