Single-column chromatographic column for electric insulation oil gas separation and preparation method

A chromatographic column, oil and gas technology, applied in the field of single-column chromatographic column, can solve problems such as complex process of single-column system and inaccurate measurement of multi-column system, and achieve the effect of simple preparation process, easy popularization and application, and high column efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

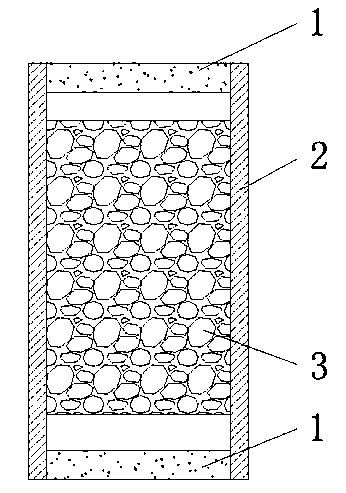

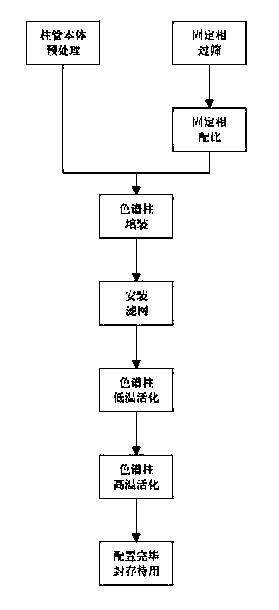

[0025] The materials used are: a) Stainless steel column tube: stainless steel column tube: stainless steel column tube with an outer diameter of φ3mm, an inner diameter of φ2mm, and a length of 6m. b) Reagent: appropriate amount of acetone (AR). c) Stationary phase: 80 mesh Hayesep D and Hayesep N at a ratio of 7:3 (by weight), totaling 10.64g.

[0026] Wash the stainless steel column tube with NaOH aqueous solution with a mass concentration of 5% and a temperature of 90°C for 5 times to remove the oil on the inner wall of the column tube, then rinse it with tap water until it is neutral, then wash it once with distilled water, and heat it in an oven to 200°C for 10 minutes.

[0027] Take two beakers and add Hayesep D stationary phase and Hayesep N stationary phase respectively, then pour acetone (AR) equivalent to 10 times the volume of the stationary phase respectively, soak for 30 minutes, then air-dry the acetone, and place the two beakers under a far-infrared lamp Bake...

Embodiment 2

[0036] The materials used are: a) Stainless steel column tube: stainless steel column tube: stainless steel column tube with an outer diameter of φ3mm, an inner diameter of φ2mm, and a length of 5m. b) Reagent: appropriate amount of acetone (AR). c) Stationary phase: 100 mesh Hayesep D and Hayesep N at 7:3 (weight ratio), a total of 8.87 (for a reasonable value) g.

[0037] Wash the stainless steel column tube with NaOH aqueous solution with a mass concentration of 10% and a temperature of 80°C for 5 times to remove the oil on the inner wall of the column tube, then rinse it with tap water until it is neutral, then wash it with distilled water once, and heat it in an oven to 200°C for 10 minutes.

[0038] Take two beakers and add Hayesep D stationary phase and Hayesep N stationary phase respectively, then pour acetone (AR) equivalent to 10 times the volume of the stationary phase respectively, soak for 30 minutes, then air-dry the acetone, and place the two beakers under a fa...

Embodiment 3

[0047] The materials used are: a) Stainless steel column tube: Stainless steel column tube is used: a stainless steel column tube with an outer diameter of φ3mm, an inner diameter of φ2mm, and a length of 4m. b) Reagent: appropriate amount of acetone (AR). c) Stationary phase: 80 mesh Hayesep D and Hayesep N at a ratio of 7:3 (by weight), totaling 7.09g.

[0048] Wash the stainless steel column tube with NaOH aqueous solution with a mass concentration of 7% and a temperature of 75°C for 5 times to remove the oil on the inner wall of the column tube, then rinse it with tap water until neutral, then wash it with distilled water once, and heat it in an oven to 200°C for 10 minutes.

[0049] Take two beakers and add Hayesep D stationary phase and Hayesep N stationary phase respectively, then pour acetone (AR) equivalent to 10 times the volume of the stationary phase respectively, soak for 30 minutes, then air-dry the acetone, and place the two beakers under a far-infrared lamp B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com