Microwave device impedance measurement calibration method

A technology of microwave devices and calibration methods, applied in measuring devices, measuring electrical variables, measuring resistance/reactance/impedance, etc., can solve the problems of limited measurement bandwidth of TRL algorithm, reduce design and processing requirements, expand working frequency band, simplify personal number effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

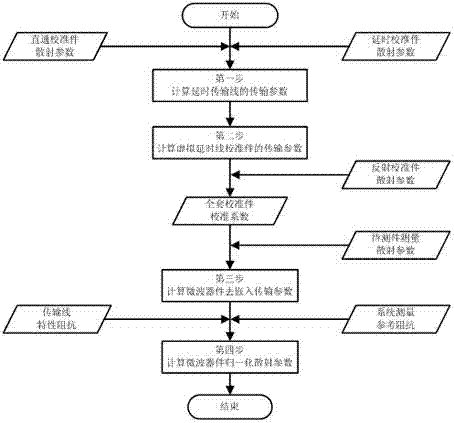

Method used

Image

Examples

Embodiment 1

[0020]

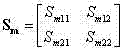

[0021] Scattering parameters of time-lapse calibration kit

[0022]

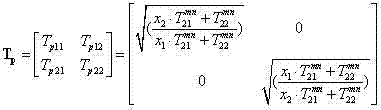

[0023] Respectively converted into transmission parameters can be obtained:

[0024] Thru Calibration Transfer Parameters

[0025]

[0026] Transmission Parameters for Time Delay Calibration Kit

[0027]

[0028] make ,in for the inverse matrix of .

[0029] Then the transmission parameters of the delayed transmission line can be expressed as

[0030]

[0031] In the formula respectively for the equation of two, and satisfy .

[0032] In the second step, the transmission parameters of the virtual delay line calibration piece are calculated. Write down the delay transmission line length contained in the original delay calibration piece as , the length of the newly added delay transmission line of the virtual delay calibration part is , then the newly added length is The transmission parameters of the virtual delay transmission line are

[0033]

[0034] Furth...

Embodiment 2

[0044]

[0045] Scattering parameters of time-lapse calibration kit

[0046]

[0047] Respectively converted into transmission parameters can be obtained:

[0048] Thru Calibration Transfer Parameters

[0049]

[0050] Transmission Parameters for Time Delay Calibration Kit

[0051]

[0052] make

[0053] Then the transmission parameter of the delayed transmission line is

[0054]

[0055] In the formula respectively for the equation of two, and satisfy .

[0056] The second step, the third step and the fourth step are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com