Machining method for preparing structurized grinding wheel through two-time fusion covering process

A structured and technological technology, applied in metal processing equipment, manufacturing tools, grinding/polishing equipment, etc., can solve the problems of affecting the quality of the grinding working layer, being unable to participate in grinding, and difficult to control the consistency of abrasive grains. Achieve the effects of overcoming the limitation of the size of the grinding wheel, improving the efficiency of cutting flow, and improving the holding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

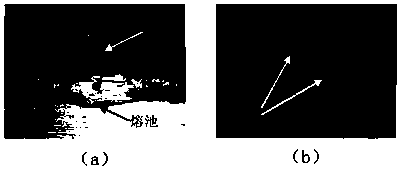

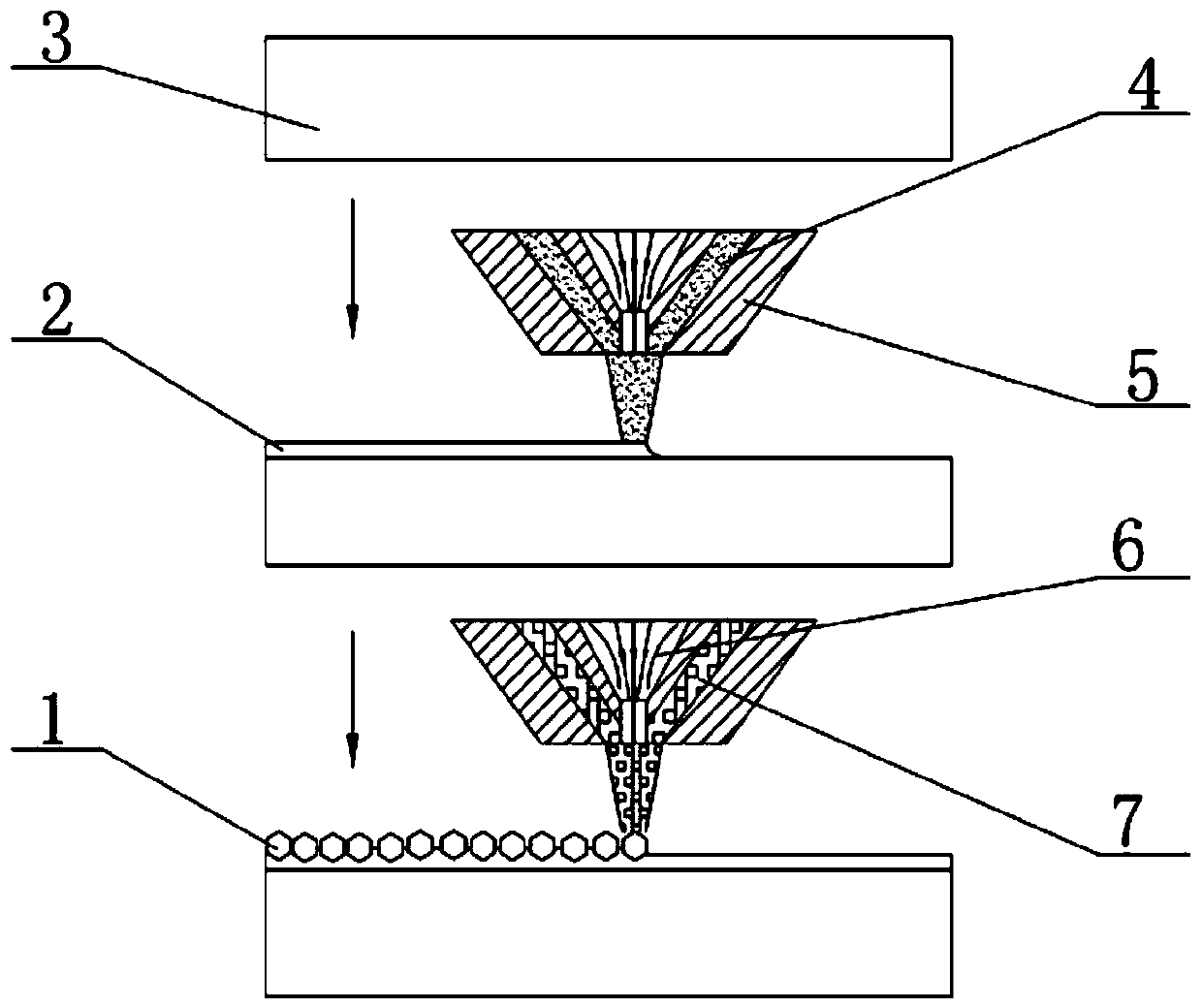

[0049] A processing method for preparing an end-face structured grinding wheel by using a secondary cladding process, the end face forms a metal bonding layer and a structured grinding working layer through a coaxial powder-feeding laser near-net forming process, and the structured grinding working layer It is composed of superhard abrasive grains and metal bond.

[0050] The end face diameter of the end grinding wheel used in this embodiment is 40mm, the length of the handle is 50mm, and the cross-sectional diameter of the handle is 15mm; the superhard abrasive grains are 120-140 mesh CBN abrasive grains, and the metal bond powder is Cu-19Sn -10Ti metal bond, 100-140 mesh atomized spherical powder.

[0051] A method for preparing a structured grinding wheel using a secondary cladding process is as follows:

[0052] S1. Pour the CBN abrasive grains and Cu-19Sn-10Ti metal bond powder into the mixing bottle according to the mass ratio of 1:3 and mix them to obtain unmixed CBN a...

Embodiment 2

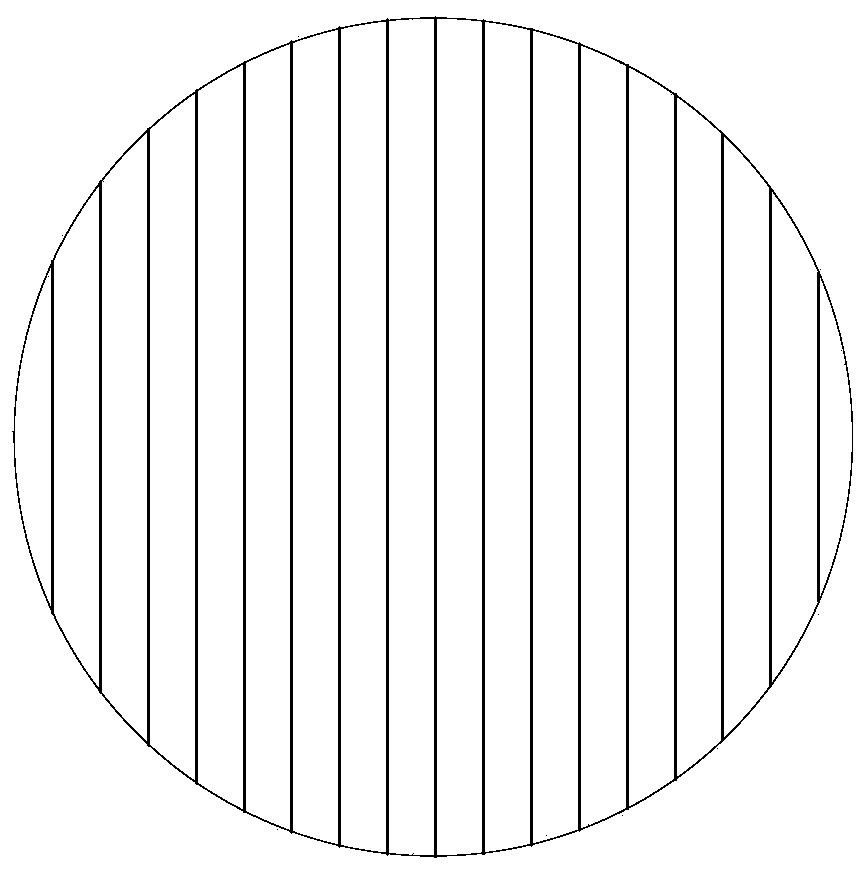

[0071] A processing method for preparing an outer circular structured grinding wheel using a secondary cladding process, the outer circular surface forms a metal bonding layer and a structured grinding working layer through a coaxial powder feeding laser near-net forming process, and the structured grinding wheel The cutting layer is composed of superhard abrasive grains and metal bond.

[0072] The diameter of the circumferential grinding wheel used in this embodiment is 40 mm, the width of the grinding working layer is 15 mm, the length of the handle is 40 mm, and the cross-sectional diameter of the handle is 15 mm.

[0073] The superhard abrasive grains are diamond abrasive grains of 270-300 mesh, and the metal bond powder is Ag-28Cu-5Ti metal bond, which is atomized spherical powder of 270-300 mesh.

[0074] A method for preparing a structured grinding wheel using a secondary cladding process is as follows:

[0075] S1. Pour the diamond abrasive grains and Ag-28Cu-5Ti met...

Embodiment 3

[0084] A processing method for preparing an end-face structured grinding wheel by using a secondary cladding process, the end face forms a metal bonding layer and a structured grinding working layer through a coaxial powder-feeding laser near-net forming process, and the structured grinding working layer It is composed of superhard abrasive grains and metal bond.

[0085] The diameter of the end face grinding wheel used in this example is 40 mm, the length of the handle is 50 mm, and the cross-sectional diameter of the handle is 15 mm; the superhard abrasive grains are 170-200 mesh diamond abrasive grains, and the metal bond powder is Ni-Cr Metal binder, atomized spherical powder of 150-200 mesh.

[0086] A method for preparing a structured grinding wheel using a secondary cladding process is as follows:

[0087] S1, according to the mass ratio of 1:2, diamond abrasive grains and Ni-Cr metal bond powder are poured into the mixing bottle and mixed to obtain unmixed diamond abr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com