Adjustable precision prism

An adjustable prism technology, applied in installation, optics, instruments, etc., can solve the problems of easy damage to prism edges and mirror surfaces, easy breakage, affecting instrument accuracy, etc., to improve applicability, save production costs, and improve measurement accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

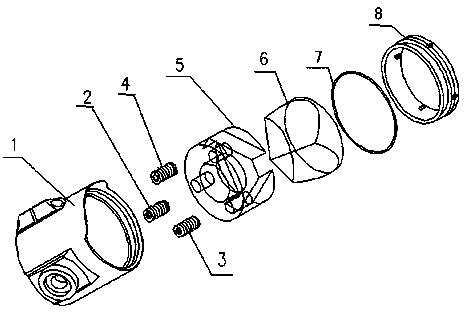

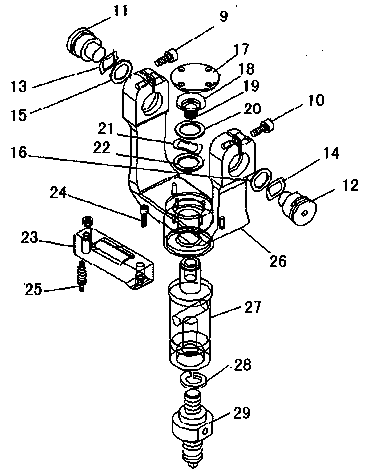

[0016] exist figure 1 Among them, the aiming part includes lens barrel 1, spring one 2, spring two 3, spring three 4, support seat 5, corner pyramid prism 6, first O-shaped waterproof ring 7 and snap ring 8. The lens barrel 1 is a cylinder made of road alloy, with a collimator on the top, an internal thread on the open end, and mounting holes on both sides; the radius of the support seat 5 and the radius of the lens barrel 1 are the same as the radius of the corner cube prism 6 , the support base 5 is used to place the corner cube 6, and its center is a through hole, and the corner cube 6 places are provided with rectangular grooves corresponding to the three edges of the corner cube 6, which is convenient for protecting the corner cube 6 edges, The right angle groove that its front is provided with, the contact of corner cube prism 6 and support seat 5 is line contact, helps to protect the face of corner cube prism 6, and the bottom of support seat 5 is provided with thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com