Developer and test method thereof

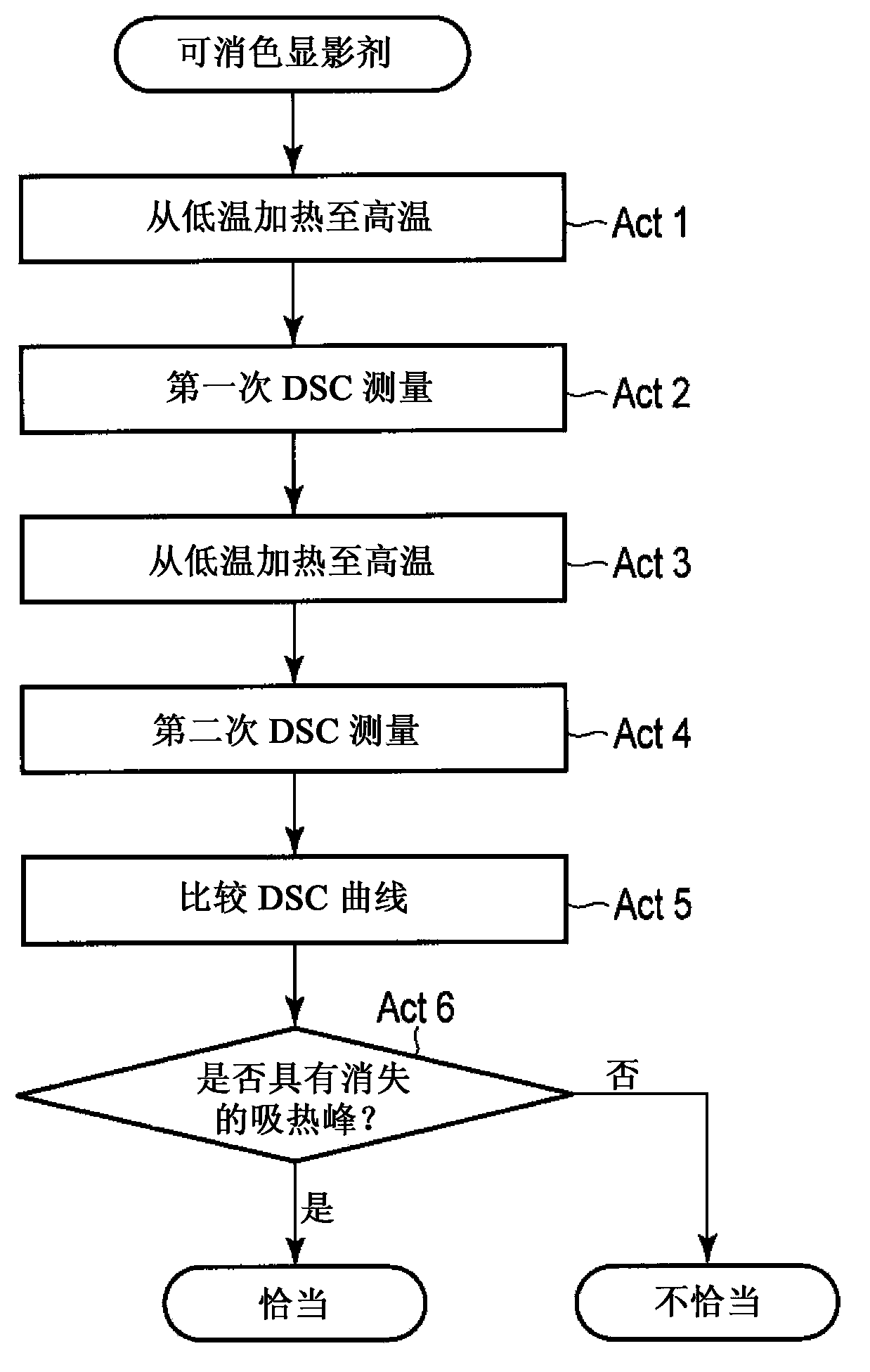

A technology of developer and color developer, applied in the direction of developer, copying/marking method, investigation stage/state change, etc., can solve problems such as time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The binder resin microparticle dispersion, the colorant microcapsule dispersion, and the mold release agent microparticle dispersion were prepared so that the colorant concentration became 15%, the release agent concentration became 10%, and the binder resin concentration became 75%. Ammonium sulfate was used as a coagulant to produce 8 μm aggregated particles, which were melted by heating to 60° C., and then cooled to obtain a colored particle dispersion. The obtained colored particle dispersion was separated from solid to liquid by a filter press, and the colored particles were washed with pure water and vacuum-dried. As additives, 2 parts by weight of hydrophobic silica and 0.5 parts by weight of titanium oxide were attached to On the surface of the toner particles, a colored toner of 8 μm was obtained.

[0056] The obtained toner was mixed with a ferrite carrier covered with silicone resin, and image output was performed on an MFP (e-studio4520c) manufactured by Toshi...

Embodiment 2

[0063] A colored toner of 8 μm was obtained in the same manner as in Example 1 except that the colorant microcapsule dispersion was changed to a colorant dispersion.

[0064] The obtained toner was stored in a freezer at -30° C. for one week to obtain a colored toner.

[0065] The obtained toner was mixed with a ferrite carrier covered with silicone resin, and image output was performed on an MFP (e-studio4520c) manufactured by Toshiba Tec. The temperature of the fixing device was set to 80° C., the paper feed speed was adjusted to 30 mm / sec, and a color developed image with an image density of 0.4 was obtained.

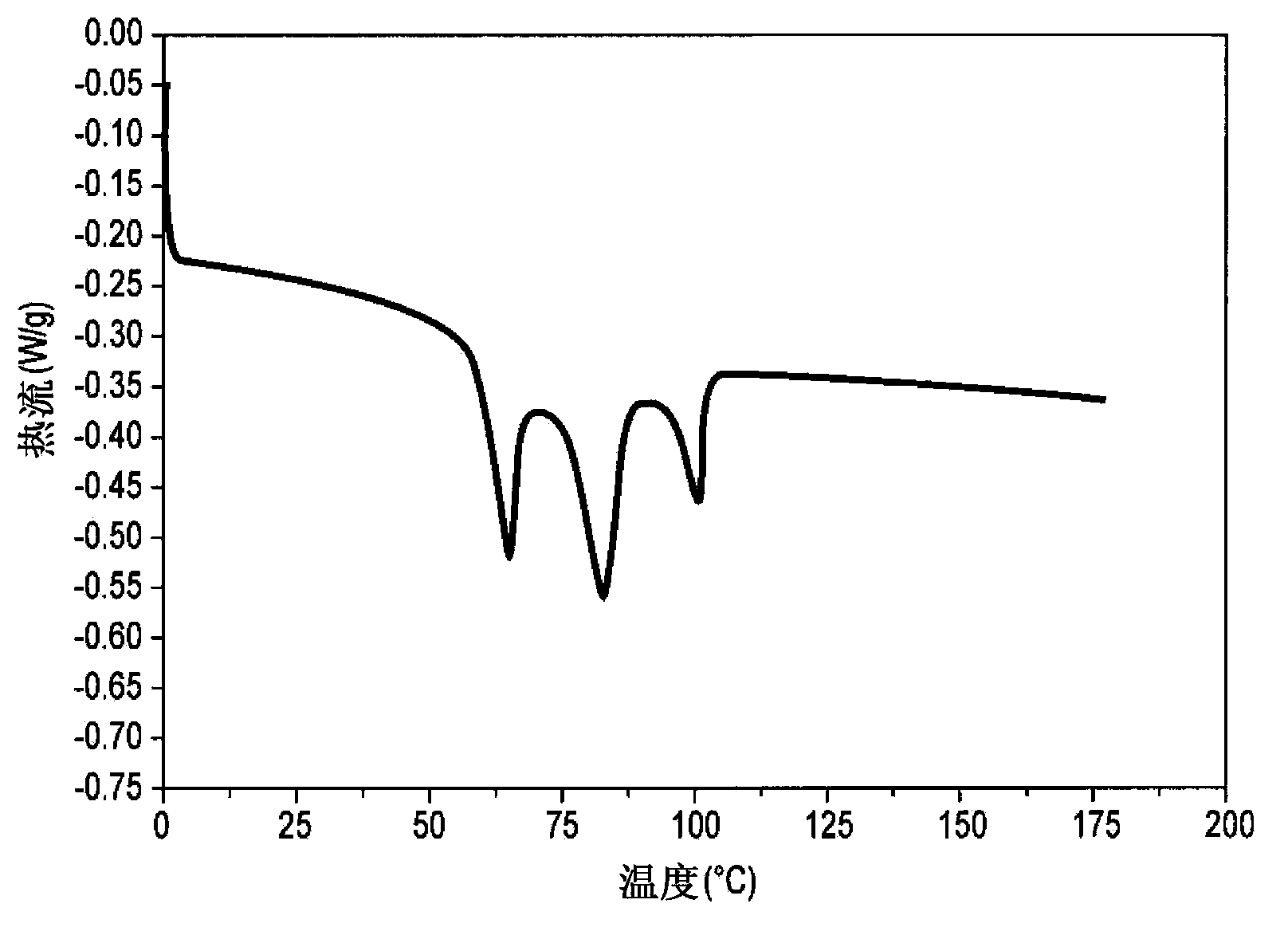

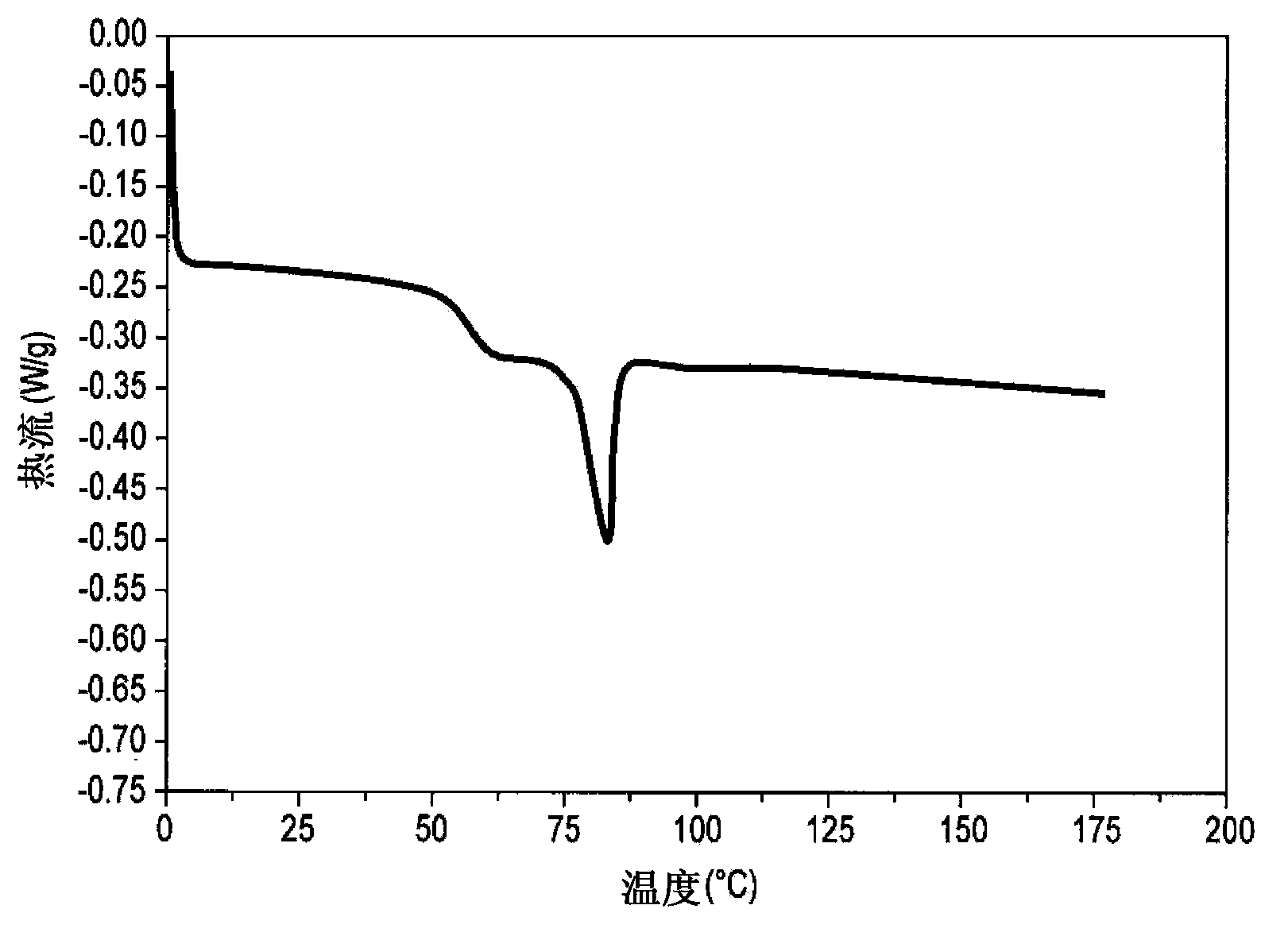

[0066] In the DSC measurement of the obtained toner, as in Example 1, in the first heating, endothermic peaks were observed at around 65°C, 80°C, and 100°C, and in the second heating, at 60°C A baseline shift due to the glass transition of the binder resin was observed nearby, an endothermic peak was observed around 80°C, and the endothermic peak around 100°C disapp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com