Temperature control system and method for semiconductor process heat treatment device

A technology of heat treatment equipment and temperature control, which is applied in the direction of temperature control using electric methods, auxiliary controllers with auxiliary heating devices, etc., which can solve the problems that it is difficult to ensure the rapid temperature rise ability of heat treatment equipment and temperature control ability, and achieve a good constant temperature Effect of control performance, process optimization, shortening process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

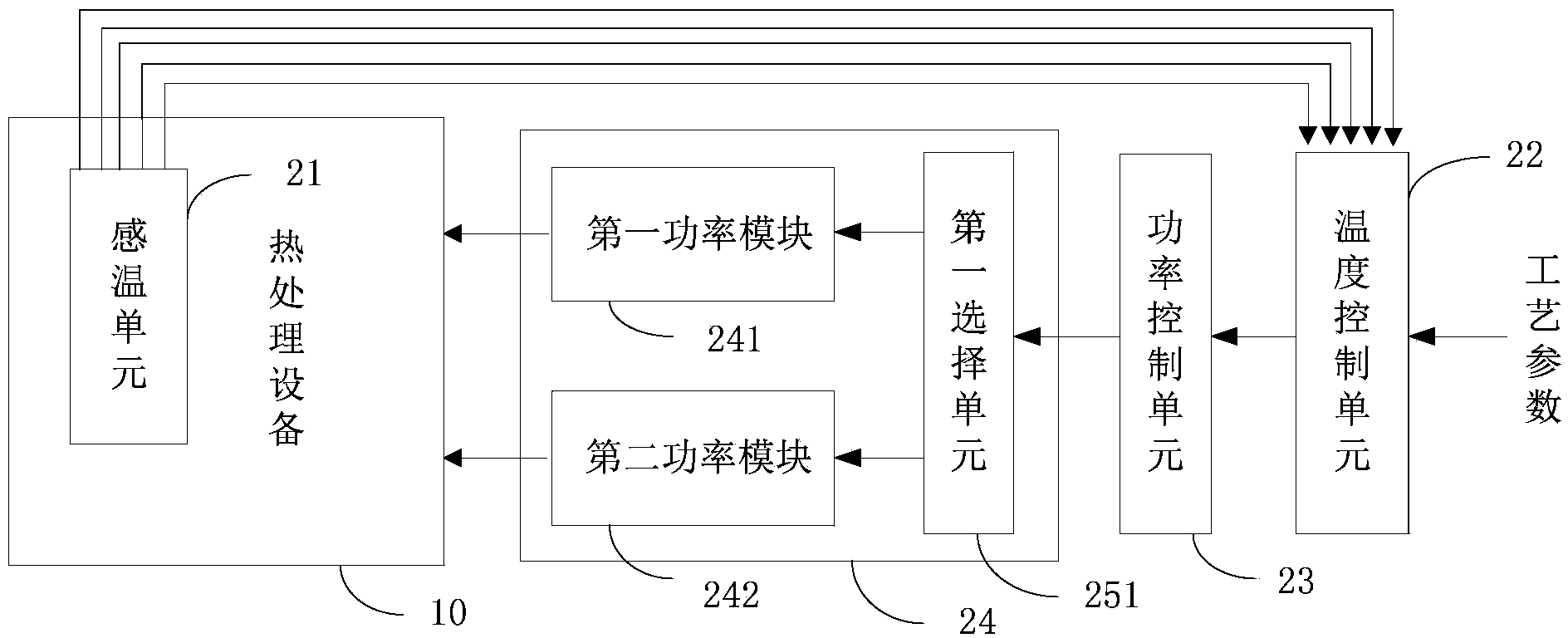

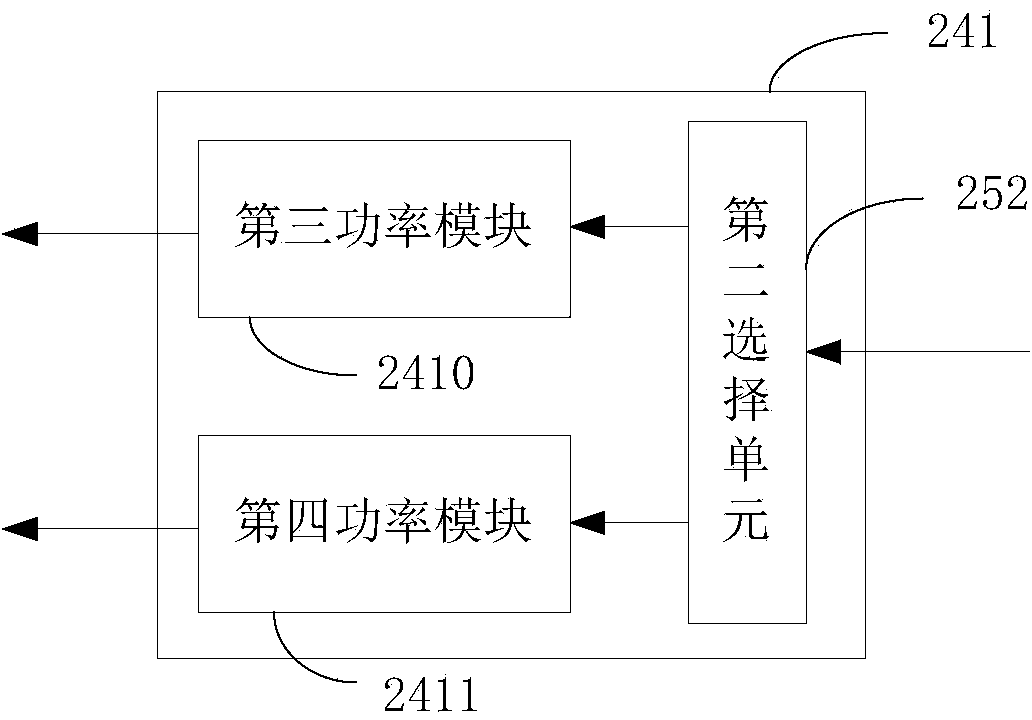

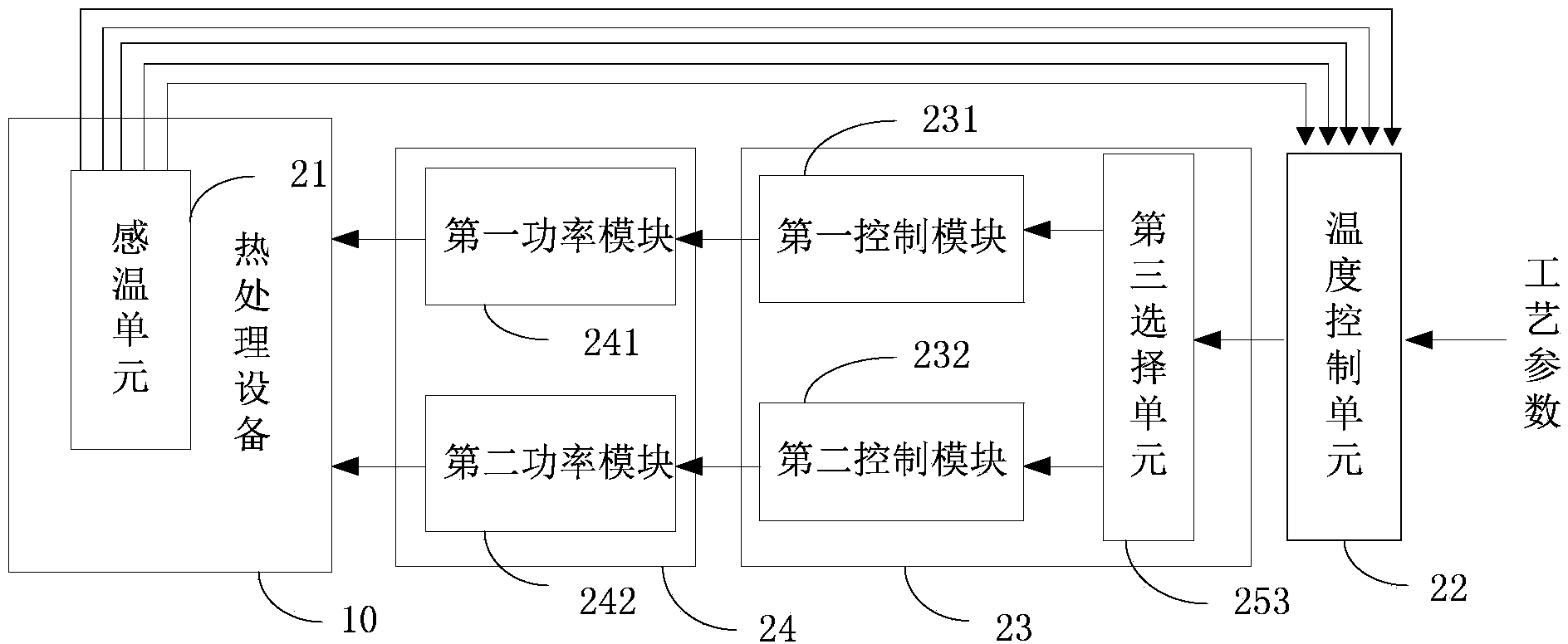

[0021] The specific embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0022] It should be noted that the temperature control system or the temperature control method provided in any embodiment of the present invention is used to control the temperature of the heat treatment equipment in the semiconductor process. In the semiconductor process, the process recipe determines the process parameters, and the process parameters at least include the target temperature value of the heat treatment equipment and its temperature rise rate in each process process. The present invention achieves the purpose of raising the temperature of the heat treatment equipment according to a set track or precisely maintaining the temperature through staged control and closed-loop control.

[0023] Such as figure 1 As shown, the power control system provided by the first embodiment of the present invention is used to control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com