Method for preparing amorphous combined magnetic powder core

A magnetic powder core and amorphous technology, applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve the problems of reduced efficiency, small effective contact surface at joints, increased core loss, etc., to achieve improved efficiency and high production efficiency , The effect of increasing the effective contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The technical solution of this embodiment is: a method for preparing an amorphous composite magnetic powder core, including the following steps:

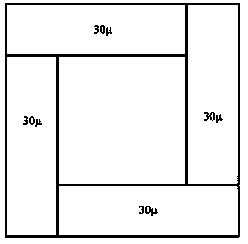

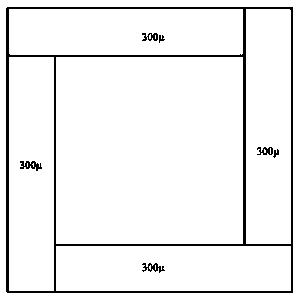

[0021] Step 1: Prepare two magnetic powder cores with a permeability difference of more than 200, the shape of the magnetic powder core is a cubic shape of equal height, and two magnetic powder cores of each permeability are prepared;

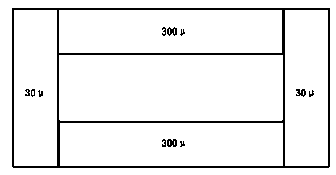

[0022] Step 2: Splicing four magnetic powder cores with magnetic conductive glue to form a combined magnetic powder core. The top view of the combined magnetic powder core is a hollow rectangle or a square, and a splicing method of connecting magnetic powder cores of different permeability is adopted.

[0023] Among them, the preparation method of the magnetic powder core is to use the mechanical crushing method to pulverize the amorphous strip into powder, screen out different particle sizes, mix the powder uniformly, soak in phosphating solution for passivation treatment, clean with deionized water,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com