Lithium ion battery separator containing poly-dopamine and ceramic coatings

A lithium-ion battery and ceramic coating technology, which is applied to battery components, circuits, electrical components, etc., can solve the problems of high requirements for equipment and increase the cost of diaphragm treatment, and achieve strong liquid absorption/retaining capacity, Effect of reducing transmission unevenness and improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

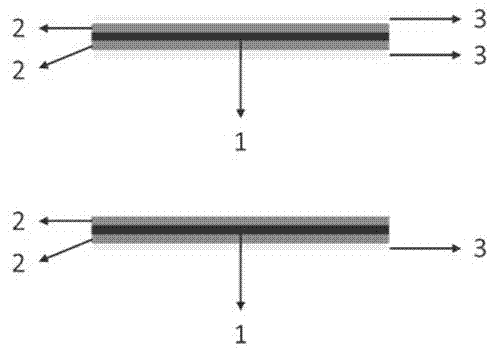

[0015] like figure 1 As shown, a lithium-ion battery separator containing polydopamine and a ceramic coating, the polymer porous membrane substrate 1 is a PP porous membrane, the thickness of the PP layer is 10 μm, the thickness of the polydopamine coating 2 is 30 nm, SiO 2 The thickness of the ceramic layer 3 is 0.5 μm. First, a layer of polydopamine layer 2 is coated on the surface of the diaphragm substrate 1, and then SiO is coated with a slurry containing the above-mentioned inorganic ceramic components. 2 The ceramic layer 3 can be obtained by drying and heat treatment. The electrochemical stability window is above 4.5V, and the separator is suitable for large-capacity lithium-ion batteries.

Embodiment 2

[0017] A lithium-ion battery separator containing polydopamine and a ceramic coating, the polymer porous membrane substrate 1 is a PE porous membrane, the thickness of the PE layer is 40 μm, the thickness of the polydopamine coating 2 is 10 nm, and the thickness of the POSS ceramic layer 3 is 5 μm. First, a layer of polydopamine layer 2 is coated on the surface of the diaphragm substrate 1, and then the POSS ceramic layer 3 is coated with a slurry containing the above-mentioned inorganic ceramic components, dried and heat-treated to obtain it. The closed cell temperature is 135°C. The modified diaphragm and the PE diaphragm were subjected to a heat resistance test at 165°C, and the PE diaphragm shrank by 33%. The modified diaphragm shrinks by 6%. This separator is suitable for high-safety lithium-ion batteries.

Embodiment 3

[0019] A lithium-ion battery separator containing polydopamine and a ceramic coating, the polymer porous membrane substrate is a PP / PE composite porous membrane, the thickness of the PP / PE composite porous membrane is 25 μm, and a layer of polydopamine coating with a thickness of 50 nm is coated , Li x La y TiO 3 The thickness of the ceramic layer is 2 μm. The diaphragm is first coated with a layer of polydopamine layer 2 on the surface of the diaphragm substrate 1, and then coated with a slurry containing the above-mentioned inorganic ceramic components. x La y TiO 3 The ceramic layer 3 can be obtained by drying and heat treatment. Compared with the PP / PE matrix, the liquid absorption rate of the modified diaphragm is increased by 1.3 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com