Preparation method of ceramic diaphragm with polydopamine as adhesive

A polydopamine and binder technology, which is applied in the direction of separators/films/diaphragms/spacers, structural parts, electrical components, etc., can solve the problem that the heat shrinkage performance is not improved, and achieve excellent cycle performance and heat resistance. The effect of obvious impact performance and thermal shock resistance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

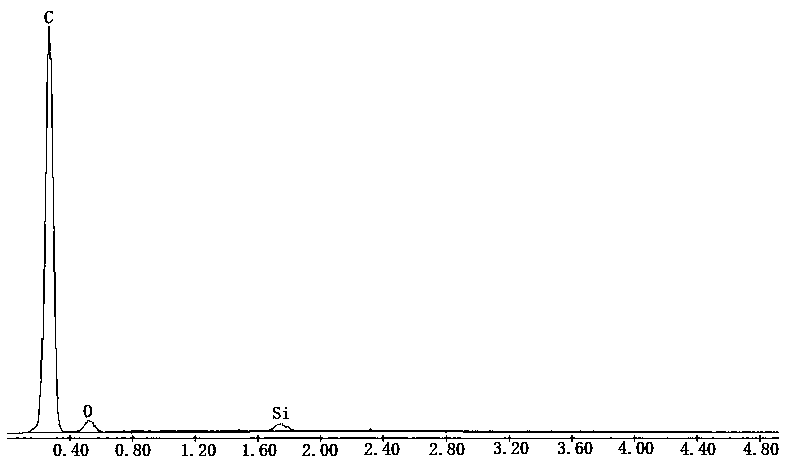

[0015] The polymer porous membrane matrix is a dry stretched PP microporous membrane with a thickness of 50 μm; the solid content of silica sol is 50%, the pH is 8.0, and the concentration of dopamine is 0.1g / L. The sample diaphragm is 10m 2 Immerse in 20kg of mixed sol system, let it stand, take it out after 4 hours, wash it with deionized water, soak it with ethanol, and dry it to prepare a modified diaphragm with polydopamine as a binder. From figure 1 It can be seen from the photoelectron spectrum of the modified diaphragm that in addition to C elements, there are Si elements and O elements on the surface of the modified diaphragm, which shows that the experiment has achieved the expected effect.

Embodiment 2

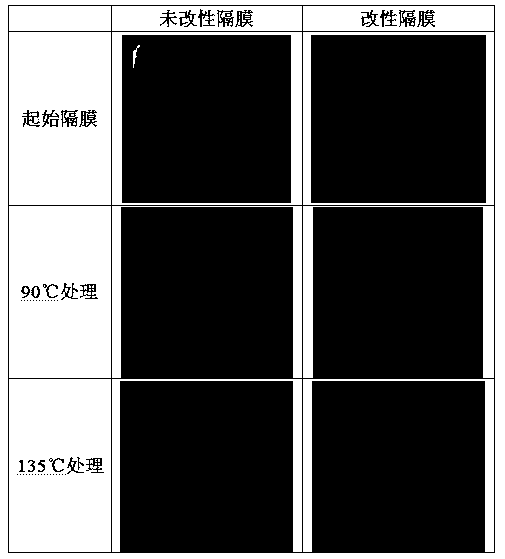

[0017] The polymer porous membrane substrate is a PE microporous membrane prepared by a wet method, with a thickness of 8 μm; the solid content of silica sol is 1%, the pH is 10.0, and the concentration of dopamine is 10g / L. The sample diaphragm is 1m 2 Spread it on a horizontal surface, pour 1kg of mixed silica sol on the surface of the diaphragm, maintain the humidity of 70% in the environment, and then take it off after 36 hours, rinse it with deionized water, soak it in ethanol, and dry it to prepare a polydopamine-bonded agent modified diaphragm. From figure 2 It can be seen from the thermal shrinkage diagram of the modified diaphragm that the thermal shrinkage of the modified diaphragm is significantly reduced. After the unmodified diaphragm is treated at 135 °C for 1 hour, the thermal shrinkage reaches 5%, while the size of the modified diaphragm has basically no change.

Embodiment 3

[0019] The polymer porous membrane matrix is PI microporous membrane with a thickness of 25 μm; the solid content of silica sol is 30%, the pH is 8.50, and the concentration of dopamine is 2g / L. The sample diaphragm is 1m 2 Spread it on a horizontal surface, pour 2kg of mixed silica sol on the surface of the diaphragm, maintain the humidity of 70% in the environment, then take it off after 16 hours, rinse it with deionized water, soak it in ethanol, and dry it to prepare a polydopamine-bonded agent modified diaphragm. The modified separator and PP / PE / PP were assembled into a button battery, and the discharge specific capacity of the modified separator battery was 1.5 times that of the unmodified one at a cycle rate of 4C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com