Battery manufacturing equipment, battery no-cavity vacuum liquid-drawing device and battery vacuum-pumping packaging method

A technology of vacuuming and vacuuming tubes, which is applied in the field of battery manufacturing equipment and its cavity-free vacuum pumping device, which can solve the problems of long vacuuming time, complex mechanism structure, frequent cleaning and maintenance, etc., to simplify the equipment structure and avoid cleaning work , The effect of reducing equipment production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

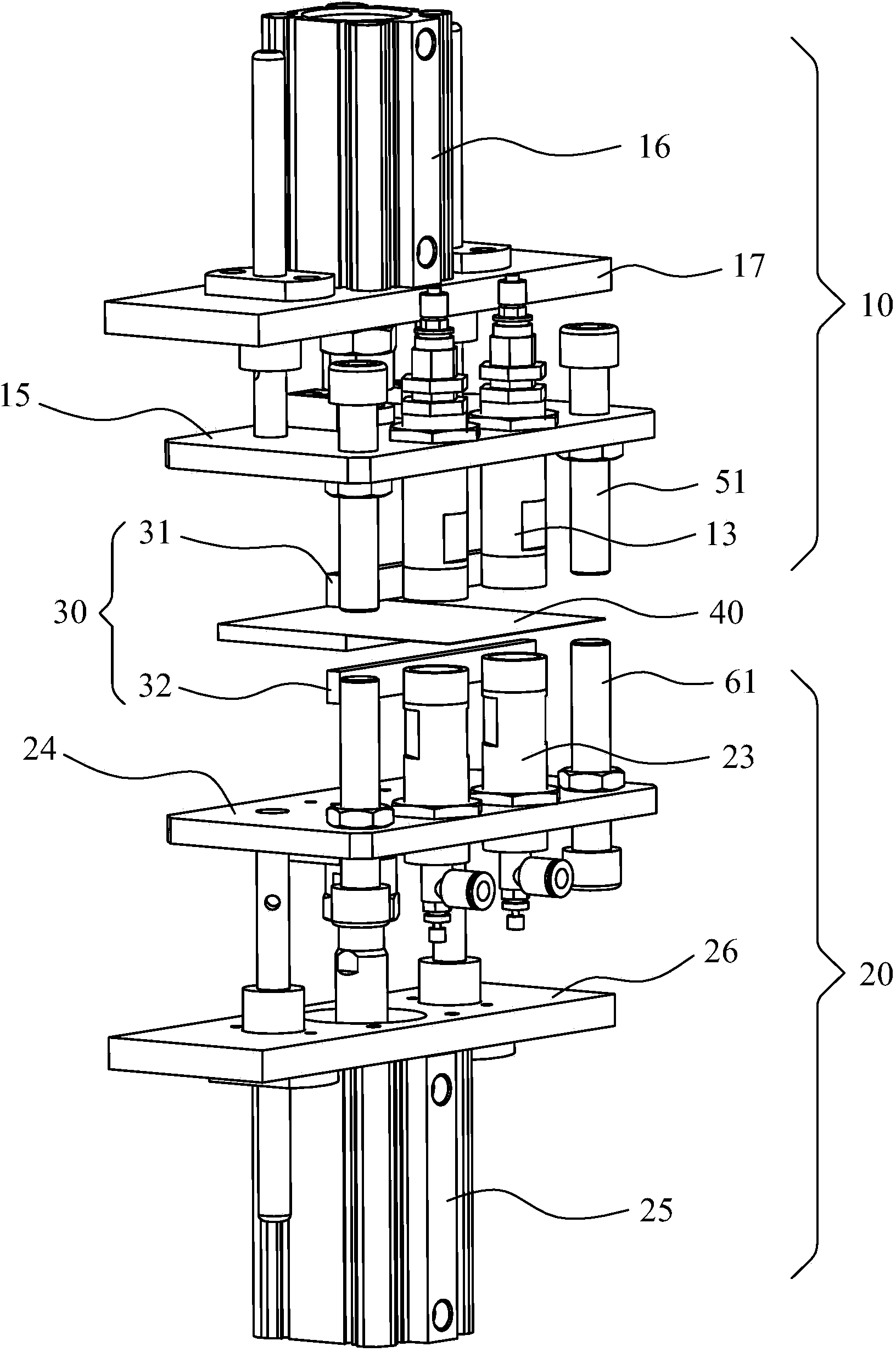

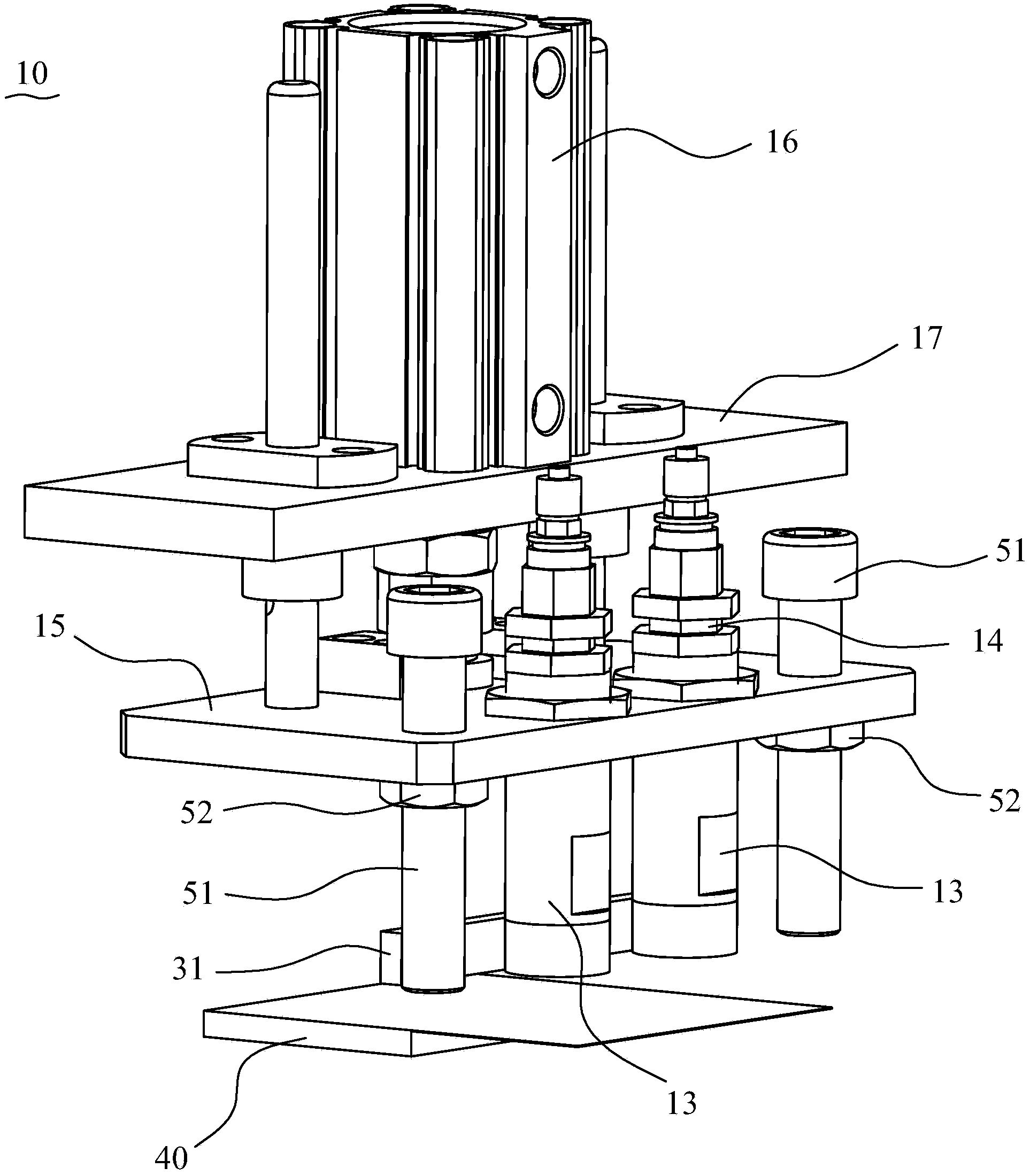

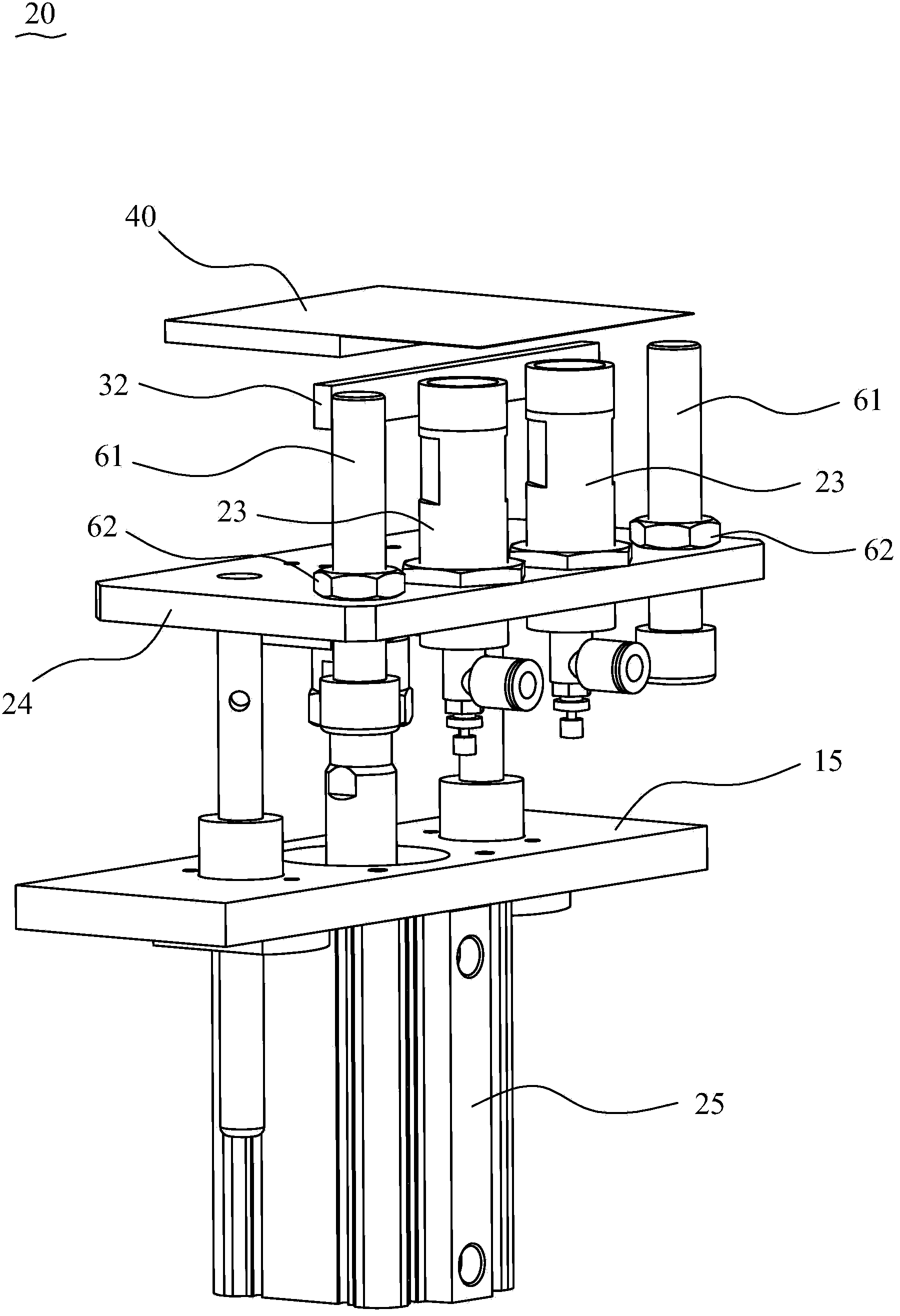

[0036] Please refer to Figure 1 to Figure 8 As shown, it shows the specific structure of a preferred embodiment of the present invention, a battery chamberless vacuum pumping device for battery manufacturing equipment. This embodiment takes lithium battery packaging as an example for illustration, including The seal piercing mechanism 10 and the sealing vacuum mechanism 20 arranged opposite to each other, and the sealing mechanism 30 located outside the seal piercing mechanism 10 and the sealing vacuum mechanism 20 .

[0037] Wherein, the seal piercing mechanism 10 includes an upper suction cup 11 , a movable bayonet 12 , a bayonet guide sleeve 13 , a bayonet driving element 14 , an upper movable seat plate 15 and an upper seat plate driving element 16 . The above-mentioned upper seat board driving element 16 is installed on the fixed plate 17 of a frame, and the fixed plate 17 is provided with two guide shafts, and the aforementioned upper movable seat plate 15 is sleeved on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com