Small-sized ferrite chip antenna

A ferrite sheet, ferrite technology, applied in the direction of the loop antenna with a ferromagnetic material core, etc., can solve the problem of strength decline and achieve the effect of avoiding attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

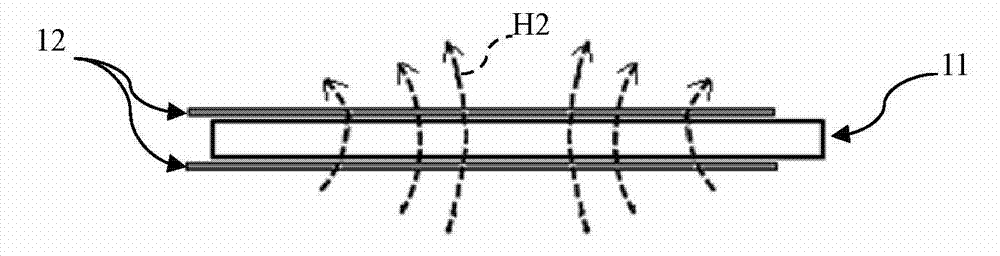

[0023] Embodiment 1: Please refer to the attached Figure 5 , firstly, according to different design requirements, use ferrite powder with different magnetic permeability, add binder, plasticizer, dispersant, etc., and prepare casting slurry by ball milling various base materials in a ball mill , In this embodiment, the magnetic permeability is preferably 70~200. Then, the LTCC wet process is used for lamination. In this embodiment, as Figure 5 The shown antenna is formed by stacking 5 layers of ferrite diaphragms 27; the specific steps are as follows: 1. Paste a layer of MIRA paper on the drool carrier board, and use screen printing technology to print metal patterns on the MIRA paper. Bottom surface electrodes 21 are formed. In the present embodiment, the antenna is in the shape of a cuboid as a whole, and there are 10 bottom surface electrodes 21 (the number of electrodes is not necessarily 10, and it is generally arranged symmetrically in an even number. How much the num...

Embodiment 2

[0026] Embodiment two: Please refer to the attached Figure 6 , the coil in this embodiment uses the same ferrite diaphragm 27 as in Embodiment 1, and the upper and lower substrates are changed to ferrite films 28 made of low permeability ferrite paste (u=4) , Low magnetic permeability materials have the advantages of good insulation performance and good magnetic permeability.

Embodiment 3

[0027] Embodiment three: Please refer to the attached Figure 7 In this embodiment, the same ferrite diaphragm 27 as in Embodiment 1 is used inside the coil, and the upper and lower substrates are replaced with ceramic films 29 made of ceramic slurry. The co-firing of ceramics and ferrite effectively solves the shortcoming of relatively brittle ferrite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com