Ratchet wheel type combined tool for fastening jumper conductor clamp in charged mode

A technology of drainage wire clips and combined tools, applied in the direction of overhead lines/cable equipment, etc., to reduce investment, improve power supply reliability, and reduce the number of power outages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

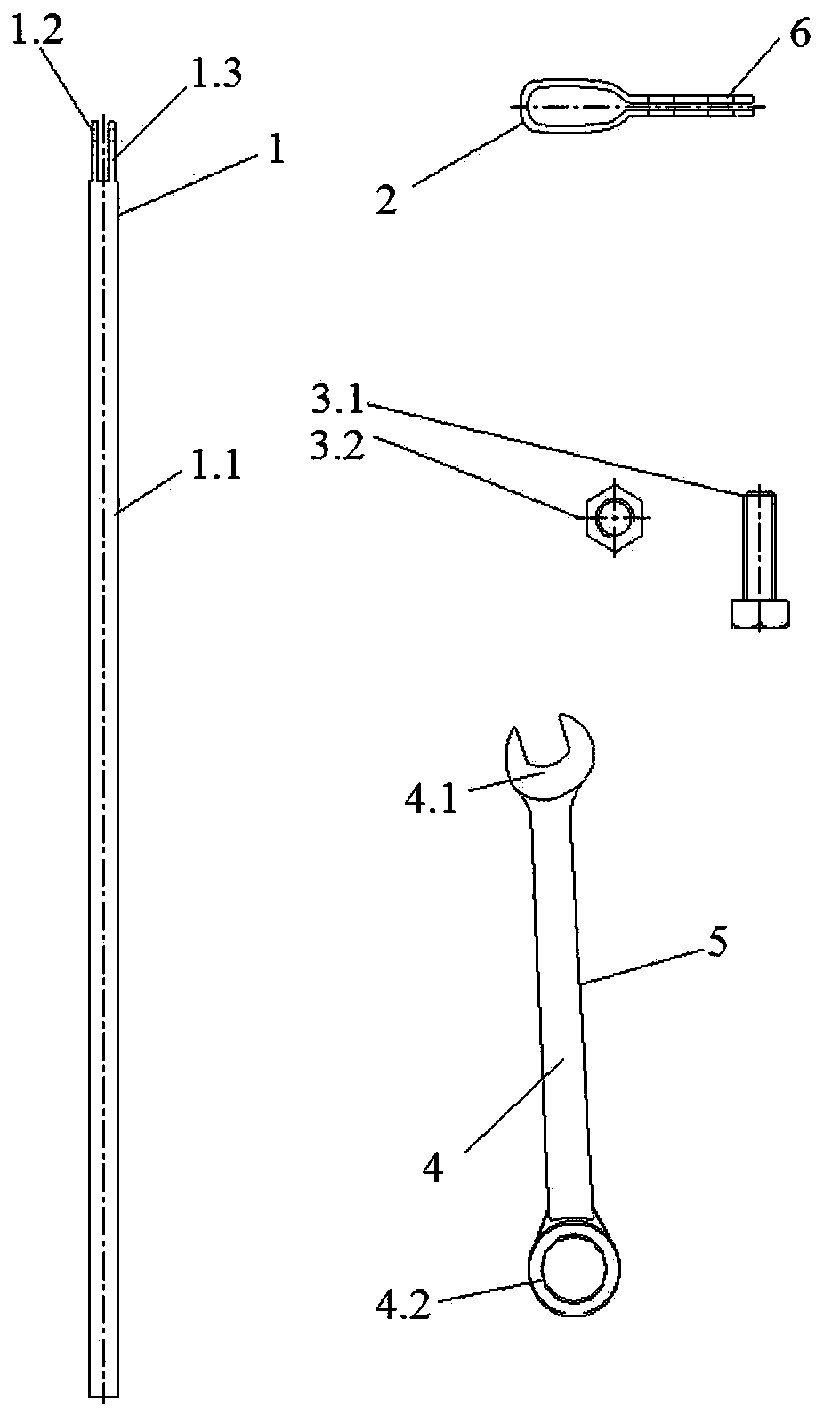

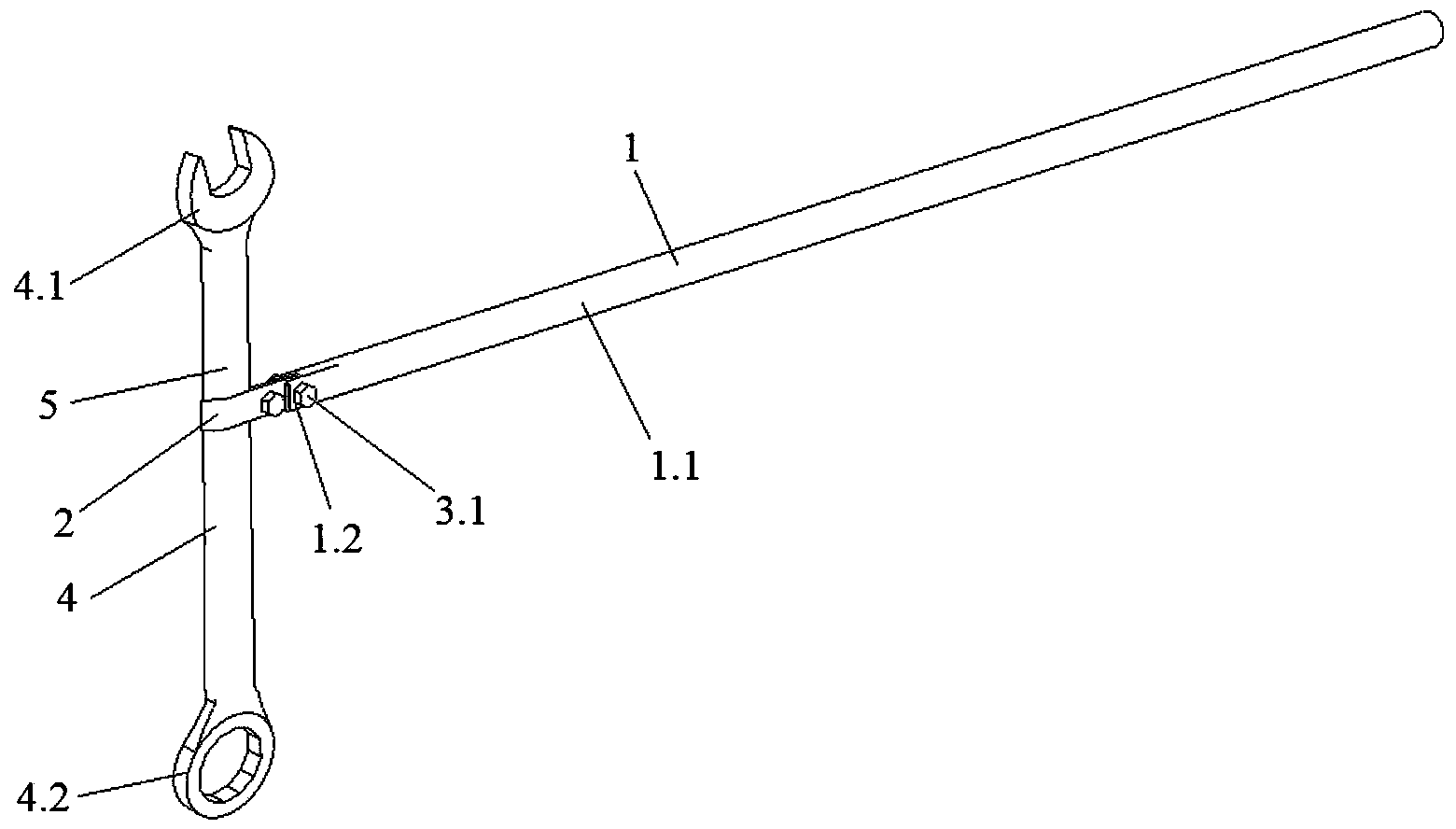

[0010] See figure 1 , figure 2 , a ratchet combination tool for fastening and draining wire clips with electricity. The invention includes a ratchet wrench 5, a coupling assembly and an insulating operating rod 1; wherein: the ratchet wrench 5 is connected to an open nut wrench 4.1 at one end of a handle 4, and a closed ratchet at one end. Wrench 4.2; the connection assembly is composed of a clamp, a through-bolt 3.1 connected to one side of the clamp, and a nut 3.2; the insulating operating rod 1 is composed of a shaft 1.1 and one end of the shaft, which is smaller than the cross-sectional shape of the shaft, and is provided with a bolt connection The clamping head 1.3 of the hole 1.2 is formed; the connection structure is that the clamp 2 of the coupling assembly clamps the handle 4 of the ratchet wrench 5, the fastening hole 6 on one side of the clamp 2 is connected with the bolt connection hole on the clamping head of the insulating operating rod 1 1.2 Correspondingly, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com