Wrapping process for manufacturing stator coil of large asynchronous high-efficiency motor

A technology for motor stators and coils, applied in laying solid insulation and other directions, can solve the problems of poor penetration of insulating impregnating paint, low withstand voltage, and poor electrical aging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

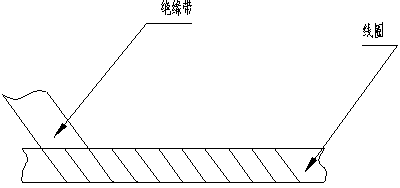

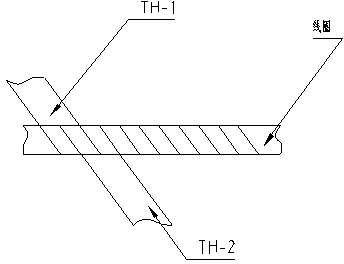

[0009] The wrapping methods for manufacturing stator coils of large-scale asynchronous high-efficiency motors include: 1. Choose TH-1 mica tape and TH-2 mica tape. 2. Stator coil wrapping must be strictly unidirectional. 3. Use TH-1 type mica tape as the innermost insulating material, and alternate layers with TH-2 type mica tape to wrap up to the specified number of layers required by the design to ensure 1 / 2 of the lapping process requirements.

[0010] exist figure 2 Among them, the TH-1 type mica tape is used as the innermost insulating material, and the TH-2 type mica tape is alternately wrapped with alternate layers until the specified number of layers required by the design to ensure 1 / 2 of the lapping process requirements.

[0011] During specific implementation, it is operated on a professional stator coil insulation wrapping machine. Install TH-1 type mica tape and TH-2 type mica tape on the two taping roller chucks of the stator coil insulation winding machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com