Shaped Stator Inserter

A special-shaped stator and paper inserting machine technology, which is applied in the direction of laying solid insulation, etc., can solve the problems of inability to meet the mass production of motors, reduce the utilization rate of workshop space, and low production efficiency, and achieve compact structure, supply speed, and increase production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

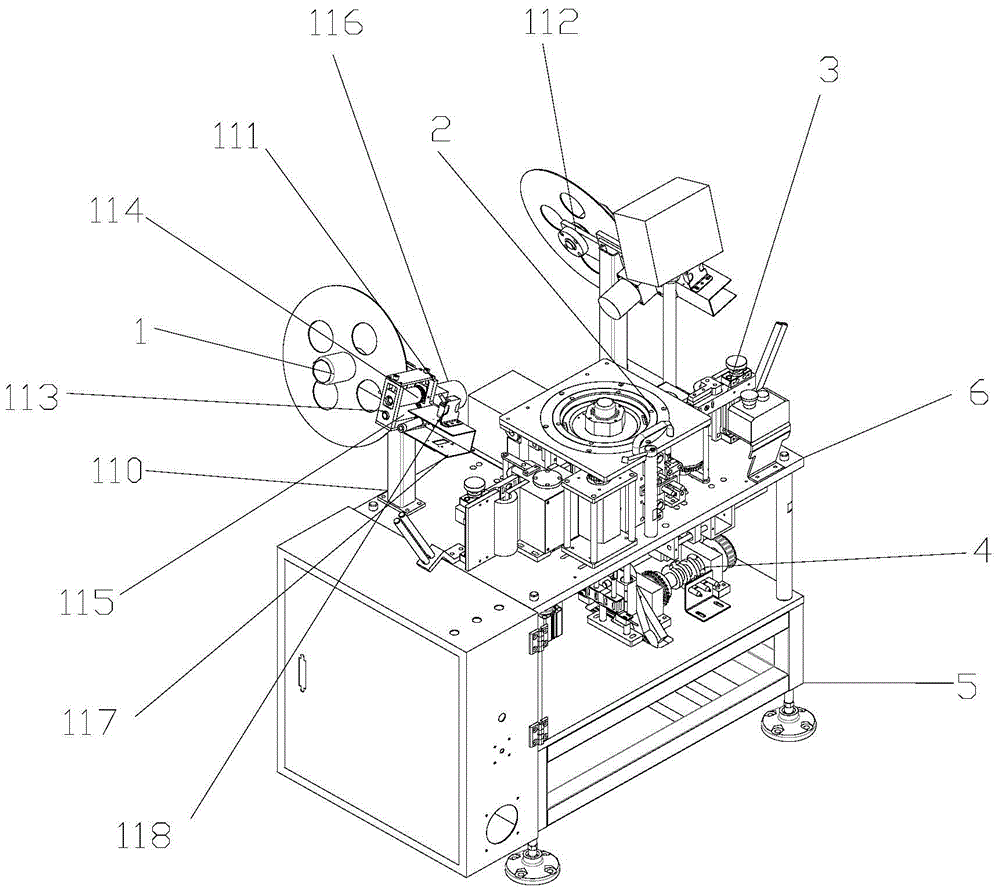

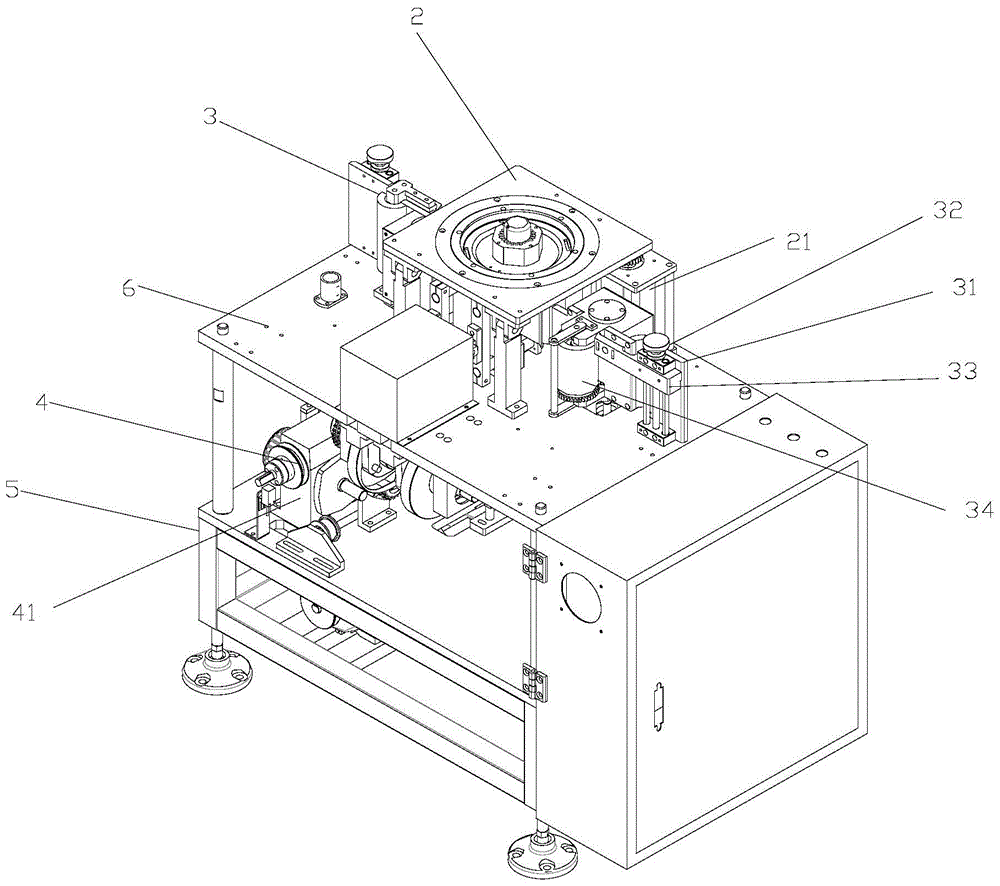

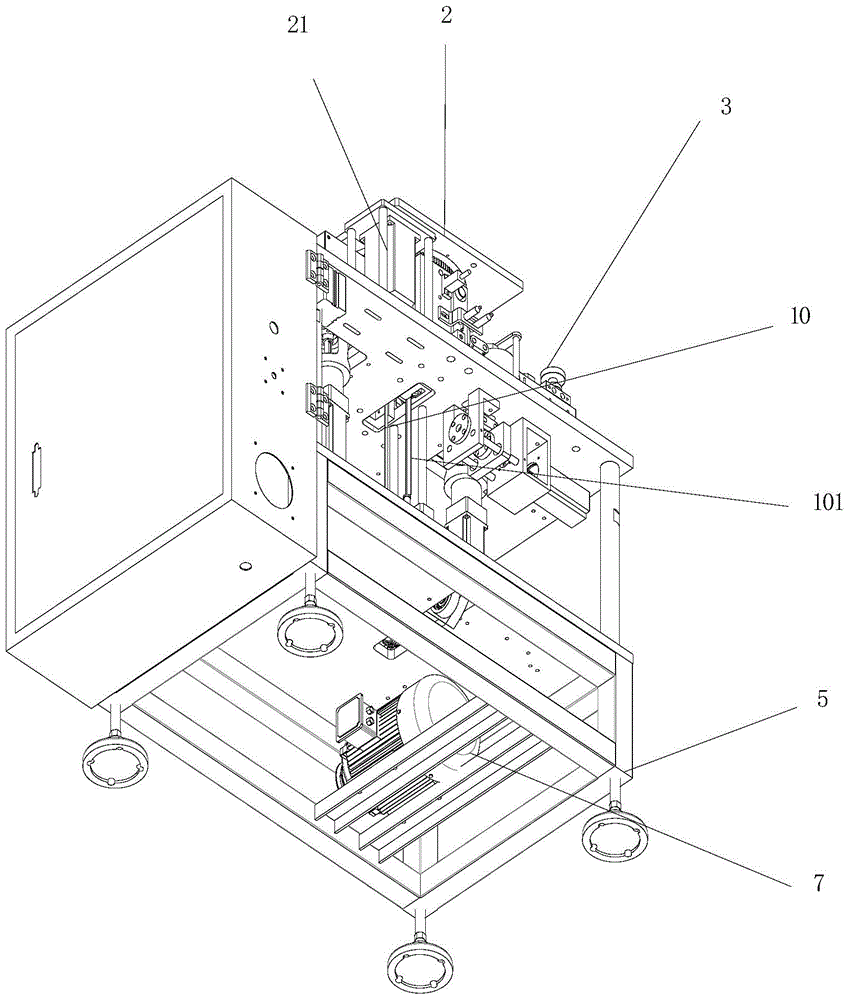

[0032] Such as figure 1 The illustrated special-shaped stator paper inserting machine includes a bracket 5, a working table 6 is formed on the upper surface of the bracket 5, a power device 7 is arranged on the bracket 5, a stator fixed indexing device 2 is arranged on the working table 6, and the stator fixed index A set of forming paper insertion mechanism is symmetrically arranged under the device, and a set of paper feeding mechanism 3 for pushing insulating paper for the forming paper insertion mechanism is also arranged on the working table. The forming paper insertion mechanism includes a cutting mechanism for insulating paper The cutting mechanism and the symmetrically arranged first molding die 8 and the second molding die 9 for molding the insulating paper, the first molding die 8 and the second molding die 9 are connected to the power device 7 through the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com