Integrated direct-current brushless motor of wheel hub

A DC brushless and electric motor technology, applied to synchronous motors with stationary armatures and rotating magnets, synchronous machine parts, etc., can solve problems such as inability to drive at high speeds, achieve improved arrangement density, small starting current, and easy maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

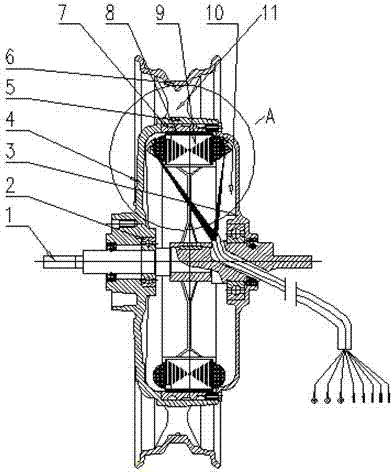

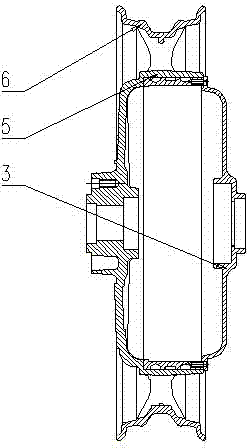

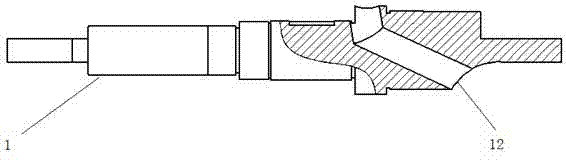

[0029] Such as figure 1 , image 3 with Figure 8 As shown, a hub integrated DC brushless motor according to the present invention includes a motor housing 10 , a motor shaft 1 , a motor end cover 4 , a stator 9 and a magnetic steel ring 7 . The motor shaft 1 is installed through the center of the motor housing 10, that is, the middle part of the motor housing 10. The motor end cover 4 is fixedly installed with the motor housing 10 through the bearing 2, forming a motor housing through which the motor shaft 1 passes. The body 10 and the motor end cover 4 are a closed combination, so that air cannot enter the inside of the motor, which is suitable for use in rain, mud and dust environments, and improves the reliability of the equipm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com