Automatic energy-saving method of asynchronous motor

An asynchronous motor, automatic technology, applied in the control of generators, motor-generator control, control of electromechanical brakes, etc., can solve the problem that the system load and frequency characteristics are not completely fixed, achieve good energy-saving control, reduce output current and excitation Current, the effect of realizing energy saving control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific examples.

[0030] An automatic energy-saving method for an asynchronous motor provided by the present invention comprises the following steps:

[0031] Step 1. Process the detected three-phase output current to obtain the active current and reactive current when the motor is running:

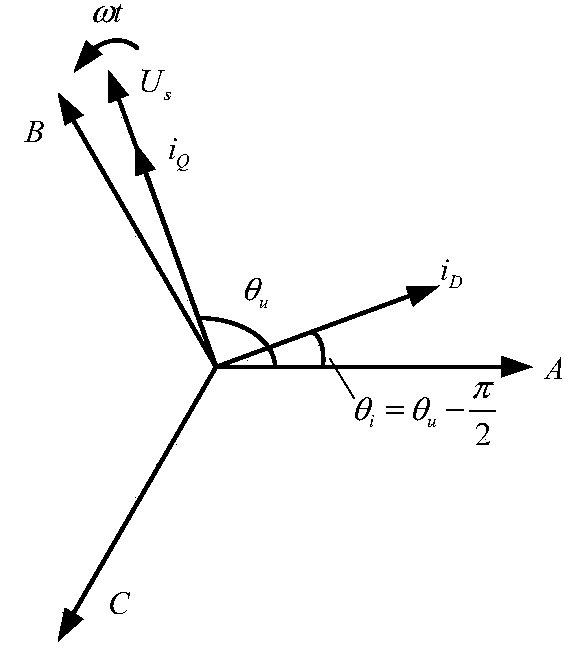

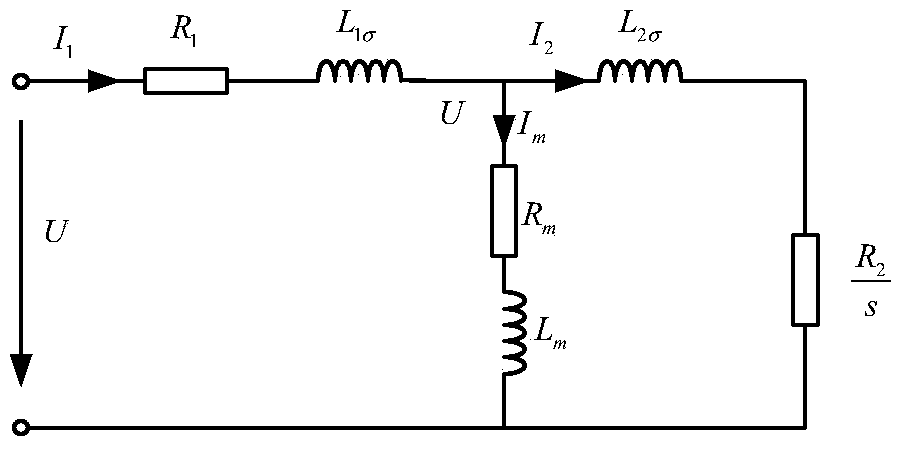

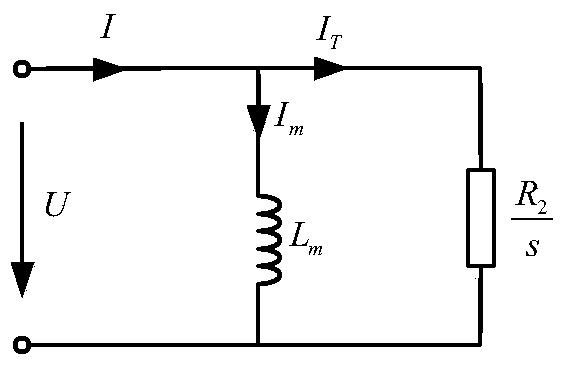

[0032] The detected three-phase output current in the stationary coordinate system is transformed into a two-phase DC that is perpendicular to each other and rotates at a synchronous speed in the rotating coordinate system through constant-amplitude Parker transformation, wherein one axis of the rotating coordinate system is oriented at the voltage On the vector, the two-phase DC corresponds to the active current and reactive current when the motor is running;

[0033] Step 2. Obtain the target value of the current voltage drop coefficient and voltage regulation coefficient: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com