Industrial wireless network oriented online debugging method and system

An industrial wireless network and debugging method technology, applied in transmission systems, electrical components, etc., can solve the problems of inconvenient system debugging, inability to understand the interaction of wireless devices, affecting network operation, etc., to achieve a clear structure, facilitate information consistency, speed up The effect of processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

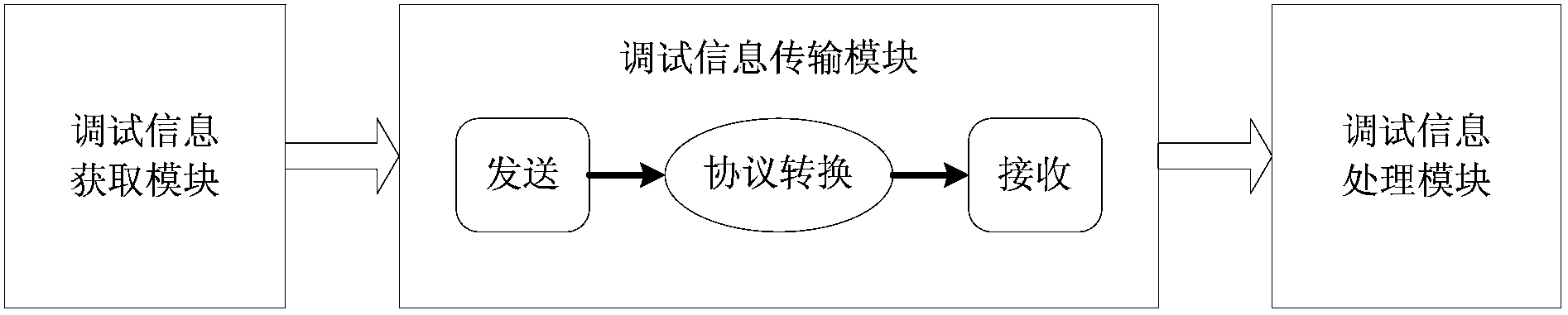

[0041] An online debugging method for industrial wireless networks designed by the present invention consists of three parts: information acquisition, transmission and processing, such as figure 1 shown.

[0042] Obtaining debugging information:

[0043] Debugging information is distributed across the lines of code of the industrial wireless network protocol stack. There are two types of debugging information: information within the protocol stack and information between protocol stacks. The information in the protocol stack includes exception information and statistical information. Every undesired event in the protocol stack is the acquisition point of abnormal information; each layer of the protocol stack successfully handles a normal event, and the corresponding statistical variable is increased by 1, which is used to ensure the consist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com