Embedded wireless passive bolt tightness state monitoring system based on surface acoustic wave technology

A state monitoring system, surface acoustic wave technology, applied in the signal transmission system, measuring torque/torsion force during tightening, measuring devices, etc., can solve problems such as incomplete inspection methods, inconvenient monitoring, hidden safety hazards, etc., and solve wiring difficulties , low cost, and the effect of reducing device insertion loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the purpose, technical solution and advantages of the present invention clearer, the technical solution of the present invention will be further described below.

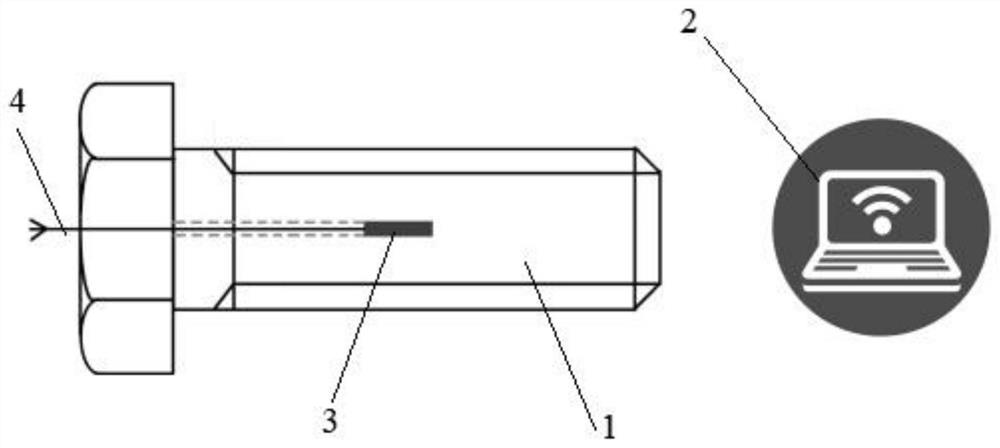

[0021] Such as figure 1 As shown, the present invention proposes an embedded wireless passive bolt tightness monitoring system based on surface acoustic wave technology, including a measurement module, a receiving module 2 and a bolt body 1; the measurement module is connected to the receiving module 2 by signals;

[0022] The measurement module includes a sensor sensitive device 3 and an antenna 4 ; the sensor sensitive device 3 is prefabricated in the bolt body 1 , one end of the antenna 4 extends out of the bolt body 1 , and the other end of the antenna 4 is connected to the sensor sensitive device 3 .

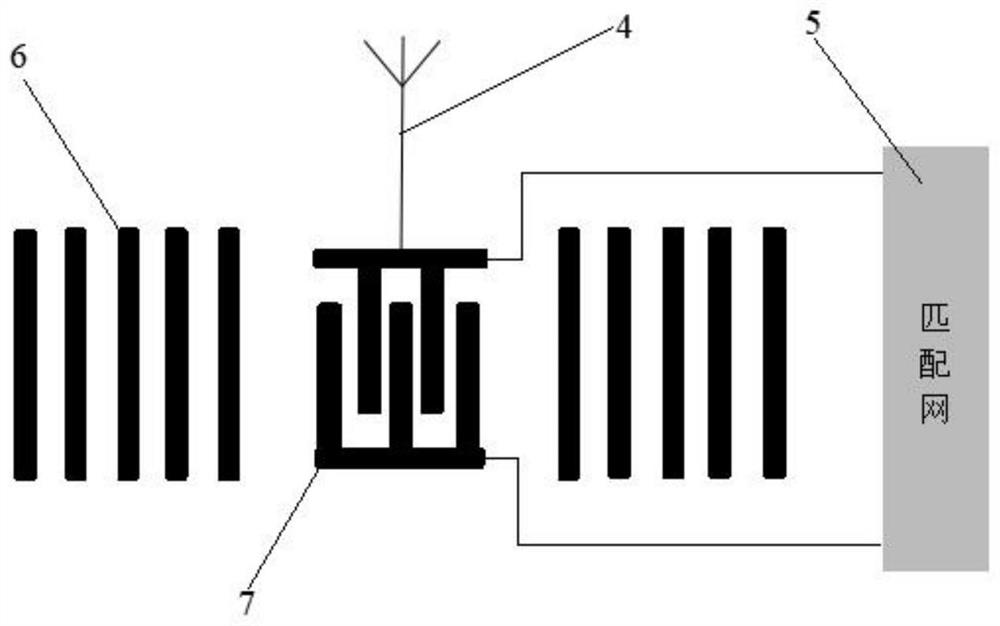

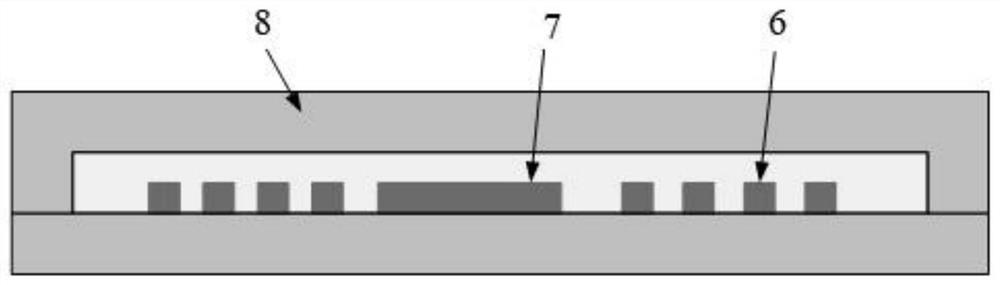

[0023] In this example, if figure 2 As shown, the sensor sensitive device 3 includes a surface acoustic wave resonator and a matching unit 5, and the matching unit 5 is signal-connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com