Surveillance camera housing

A technology for monitoring cameras and protective covers, which is applied to cameras, image communications, and camera bodies, etc. It can solve the problems of easy accumulation of dust and high equipment damage rate, and achieve the effects of blocking rain and snow splashing, improving lens life, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings, so as to facilitate the understanding of those skilled in the industry:

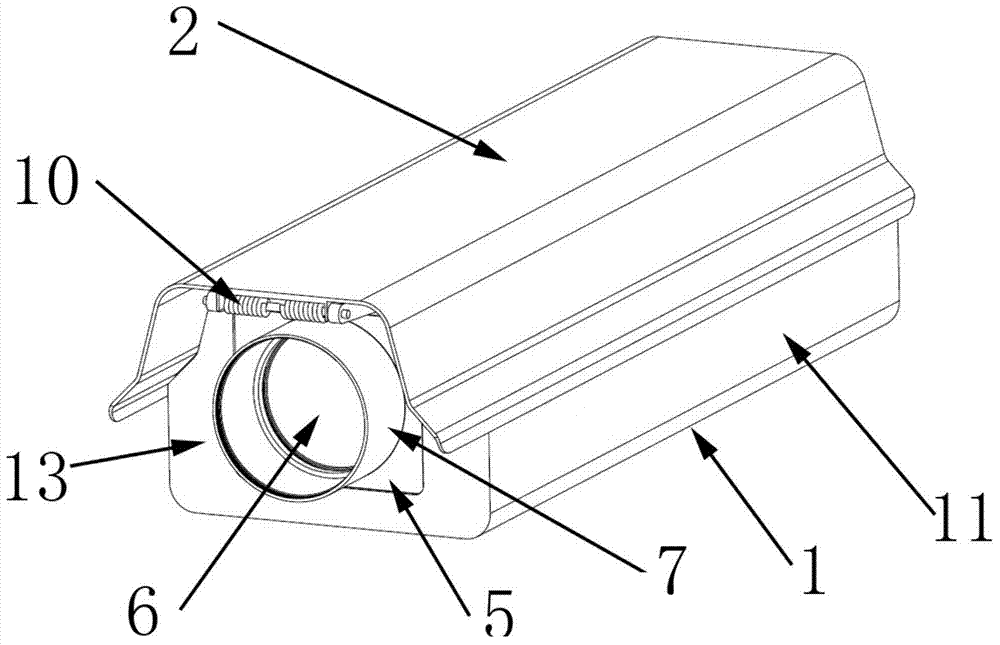

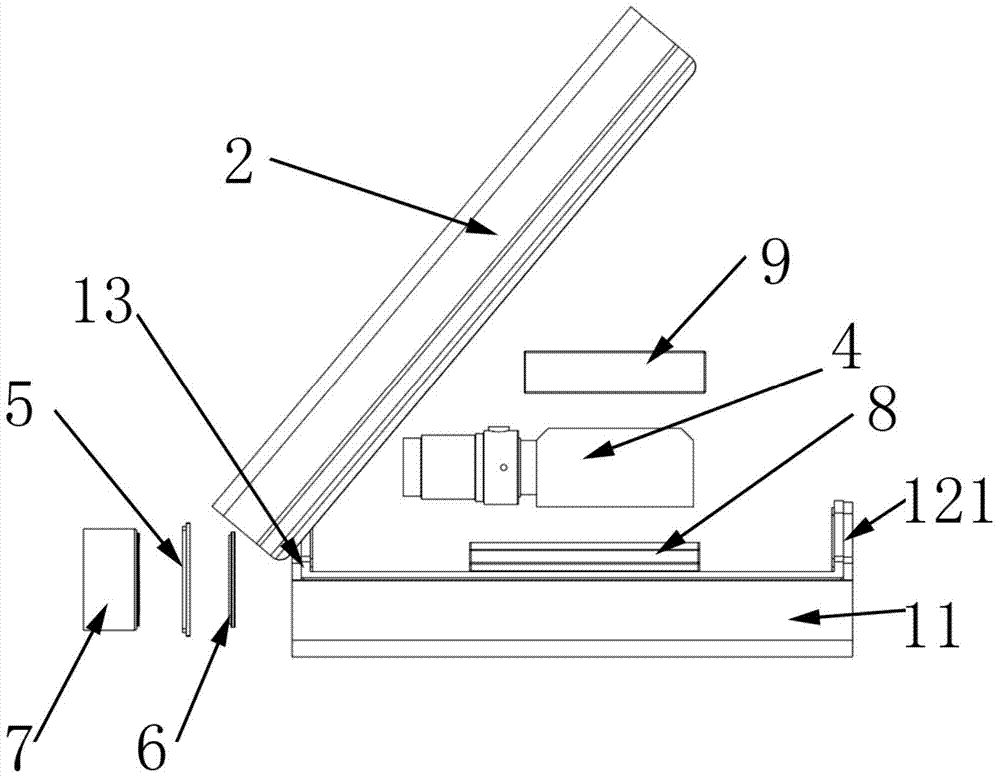

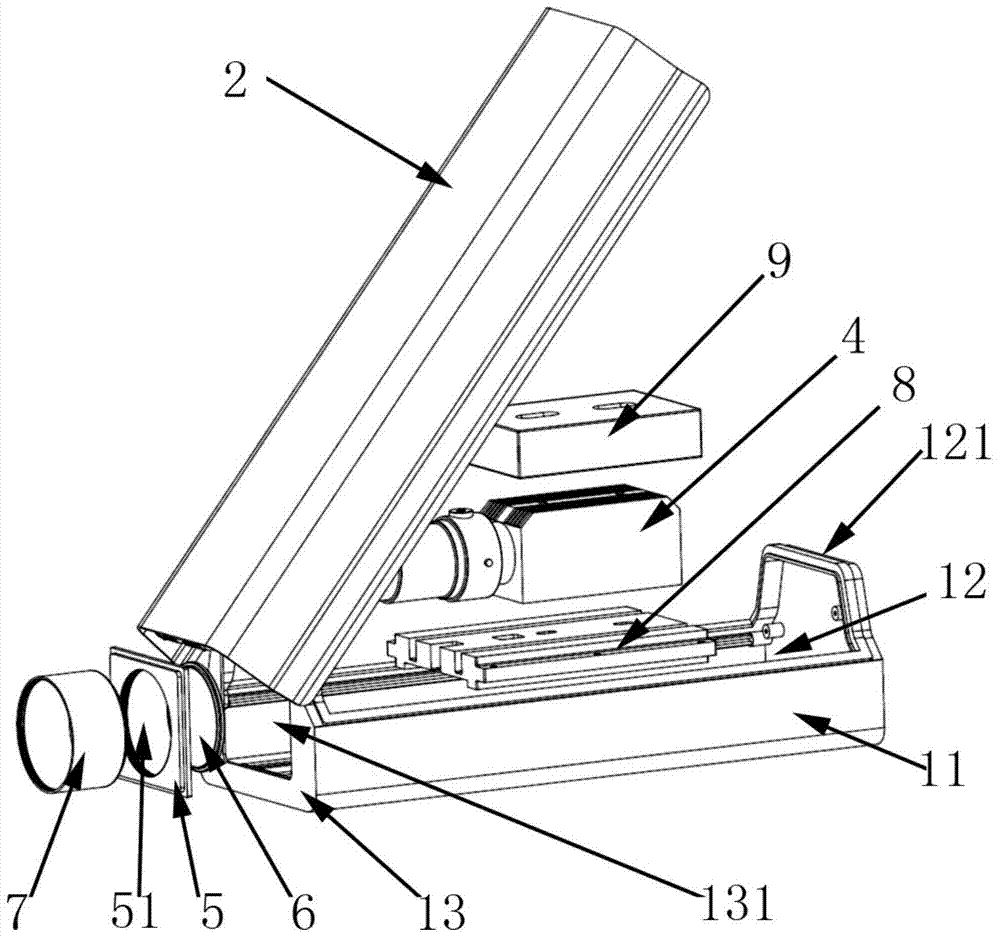

[0026] Such as Figure 1-6 As shown, the labels respectively indicate:

[0027] Housing 1, side plate 11, rear end plate 12, protrusion 121, front wall 13, opening 131, bottom plate 14, cover 2, support frame 3, proximal support 31, bottom wall 311, vertical wall 312, first arc -Shaped groove 313, second arc-shaped groove 314, middle support 32, base plate 321, first side plate 322, second side plate 323, distal support 33, bottom wall 331, standing wall 332, first arc-shaped groove 333, long Slot 334, camera 4, baffle 5, round hole 51, flange 52, UV mirror 6, light-shielding tube 7, wave crest 71, wave trough 72, heat sink 8, radiator 9, hinge 10.

[0028] See Figure 1-2 As shown, this embodiment provides a surveillance camera protective cover. The main structure of the protective cover incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com