Composite shoulder strap for underwear and manufacturing method thereof

A technology for shoulder straps and underwear, which is applied to shoulder straps, bras, and devices for pulling clothes, etc., can solve the problems of increased shoulder and neck pressure, poor durability, poor wearing comfort, etc., to ensure comfort. and durability, good breathability and moisture permeability, and the effect of improving sports comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

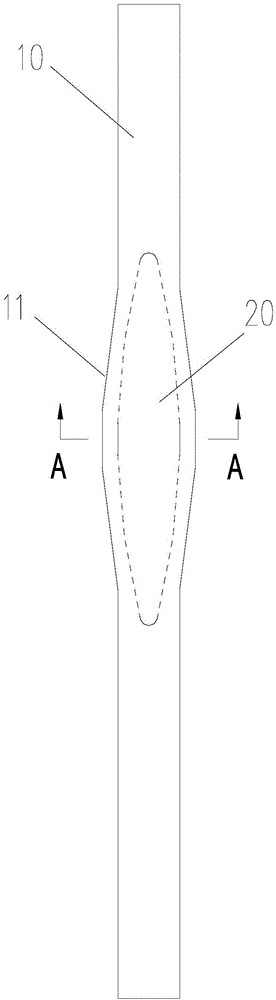

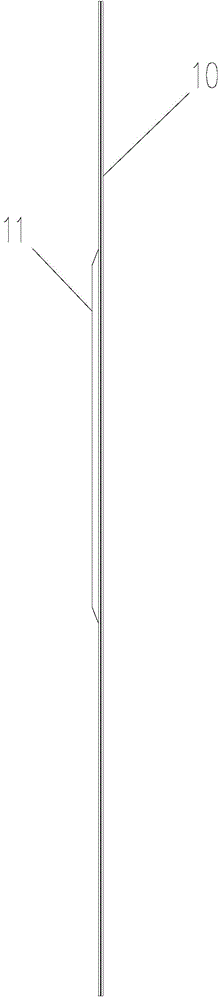

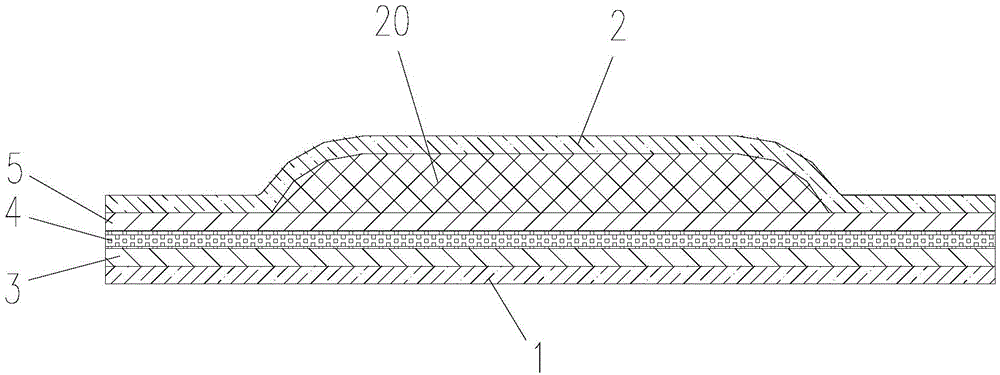

[0026] See Figure 1 to Figure 3 , An underwear composite shoulder strap, which includes a long shoulder strap body 10 made of double-layer fabrics attached to each other. The shoulder strap body 10 has a force receiving portion 11 whose width is greater than the two ends in the middle along the length of the shoulder strap body 10 A silicone sheet 20 is fixed inside the double-layer fabric at the force receiving portion 11, and the shoulder strap body 10 bulges in the thickness direction at the position where the silicone sheet 20 is fixed. The shape of the silicone sheet 20 is a spindle shape, and air holes (not shown in the figure) are opened in the thickness direction of the silicone sheet.

[0027] See image 3 The double-layer fabric includes a bottom fabric 1 and a surface fabric 2 arranged in order from bottom to top. The bottom fabric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com