A non-film-coated breathable silicone breast pad and its manufacturing method

A breathable, silica gel technology, applied in clothing, bras, applications, etc., can solve the problems of inability to effectively form curved surfaces, poor durability, and unsuitable for cleaning with water, and is suitable for large-scale production, easy to form serialization, and good appearance Beautiful and novel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

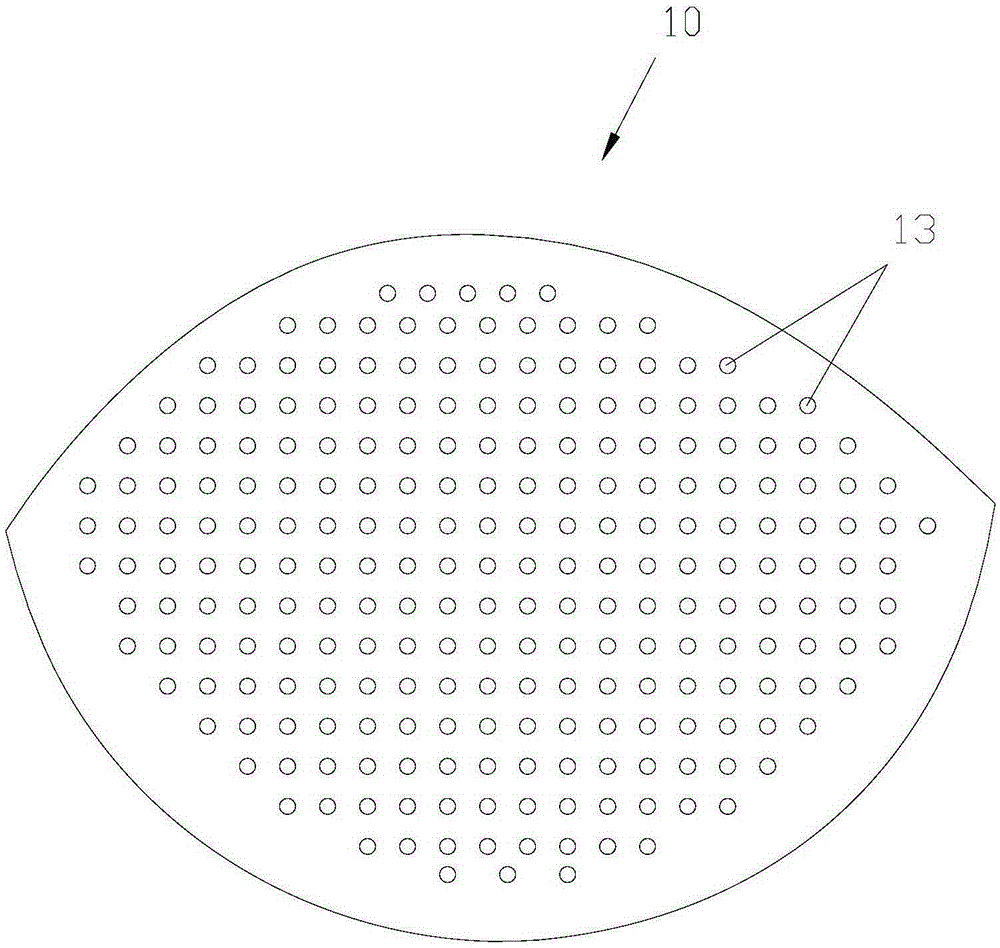

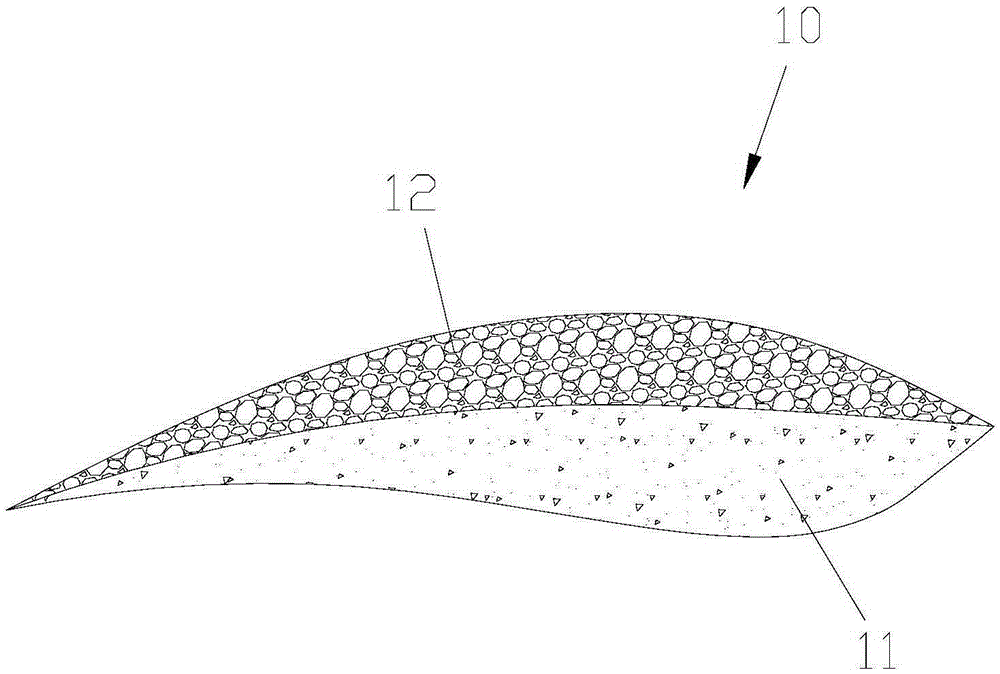

[0023] see figure 1 and figure 2 , a non-film-coated breathable silicone breast pad, comprising a silicone breast pad body 10, the silicone breast pad body 10 at least including a silicone gel bottom layer 11 and an organic silicon gel layer layered from bottom to top along the thickness direction and combined together The hardness of the silicone gel surface layer 12 and the silicone gel bottom layer 11 is greater than that of the silicone gel surface layer 12, and the silicone gel bottom layer 11 contains light polymer microbead fillers. The silicone breast pad body 10 is penetrated with air holes 13 along its thickness direction. In this embodiment, the silicone breast pad body 10 has a double-layer structure, and in other embodiments, it may also have three or more layers.

[0024] The surface of the organic silicon gel bottom layer 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com