Stacked fruit and vegetable juice extractor

A juice extractor, stacked technology, applied in the field of large industrial juice extractors, to achieve the effects of shortening the discharge distance, increasing production capacity, and strengthening the self-cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but do not limit the present invention in any way.

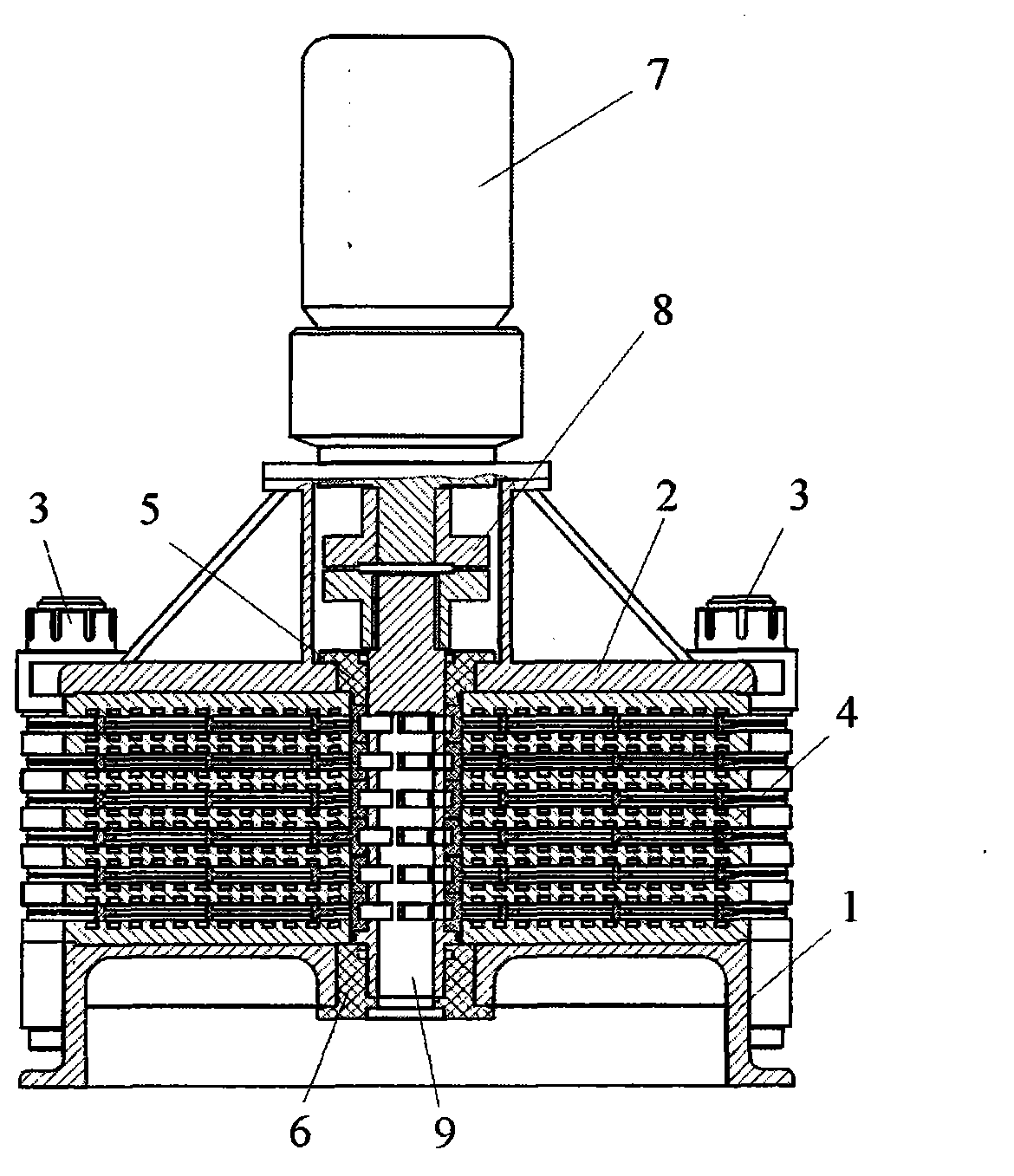

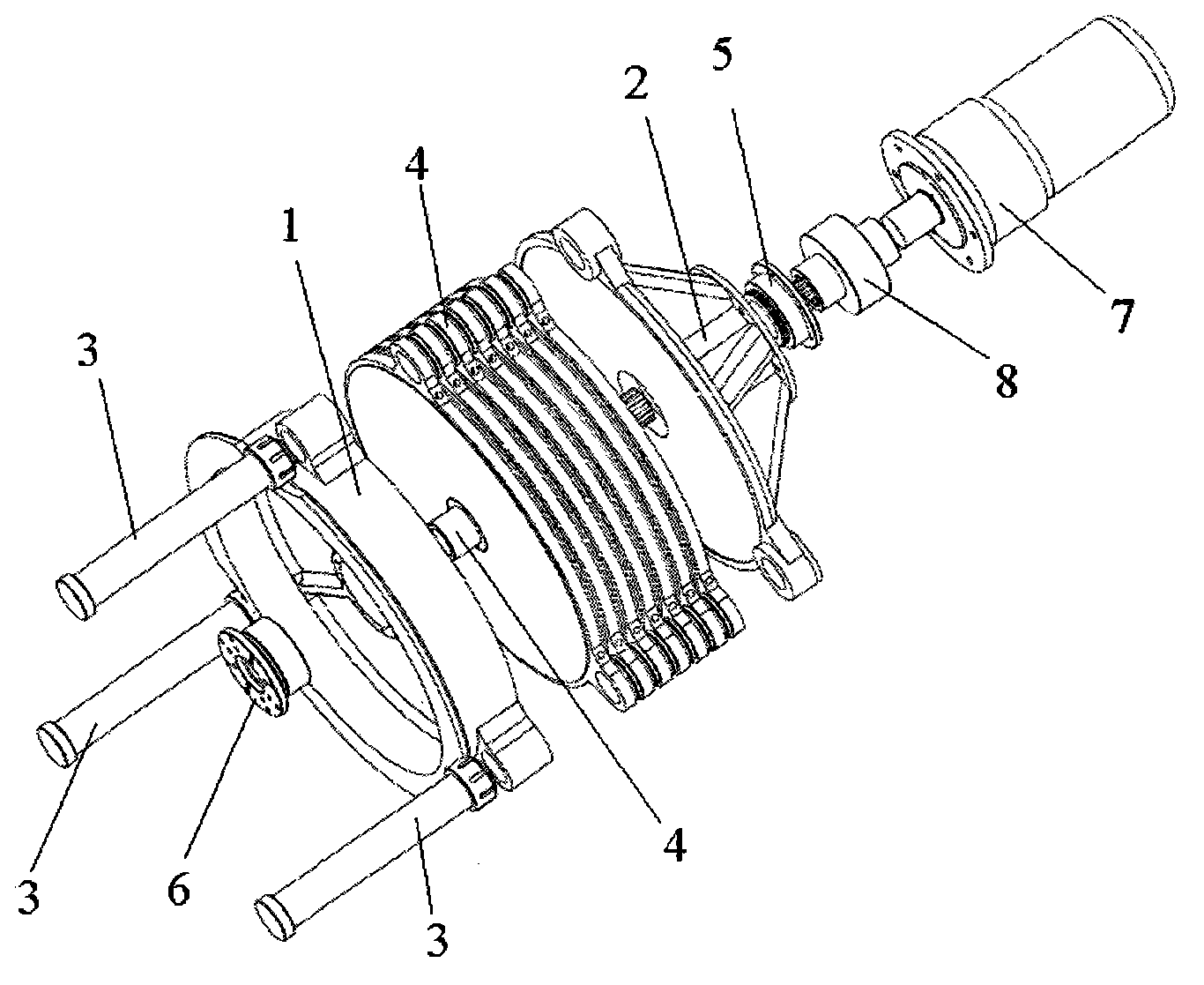

[0028] A stacked fruit and vegetable juicer equipped with 6 sets of filter press units consists of a drive motor (7), a coupling (8), an upper cover (2), an upper seal bearing (5), a drive shaft (9), a filter press The unit group (4), the lower sealing bearing (6), the base (1), and the locking guide post (3) are composed, wherein the filter press unit group (4) is composed of 6 groups of filter press units laminated.

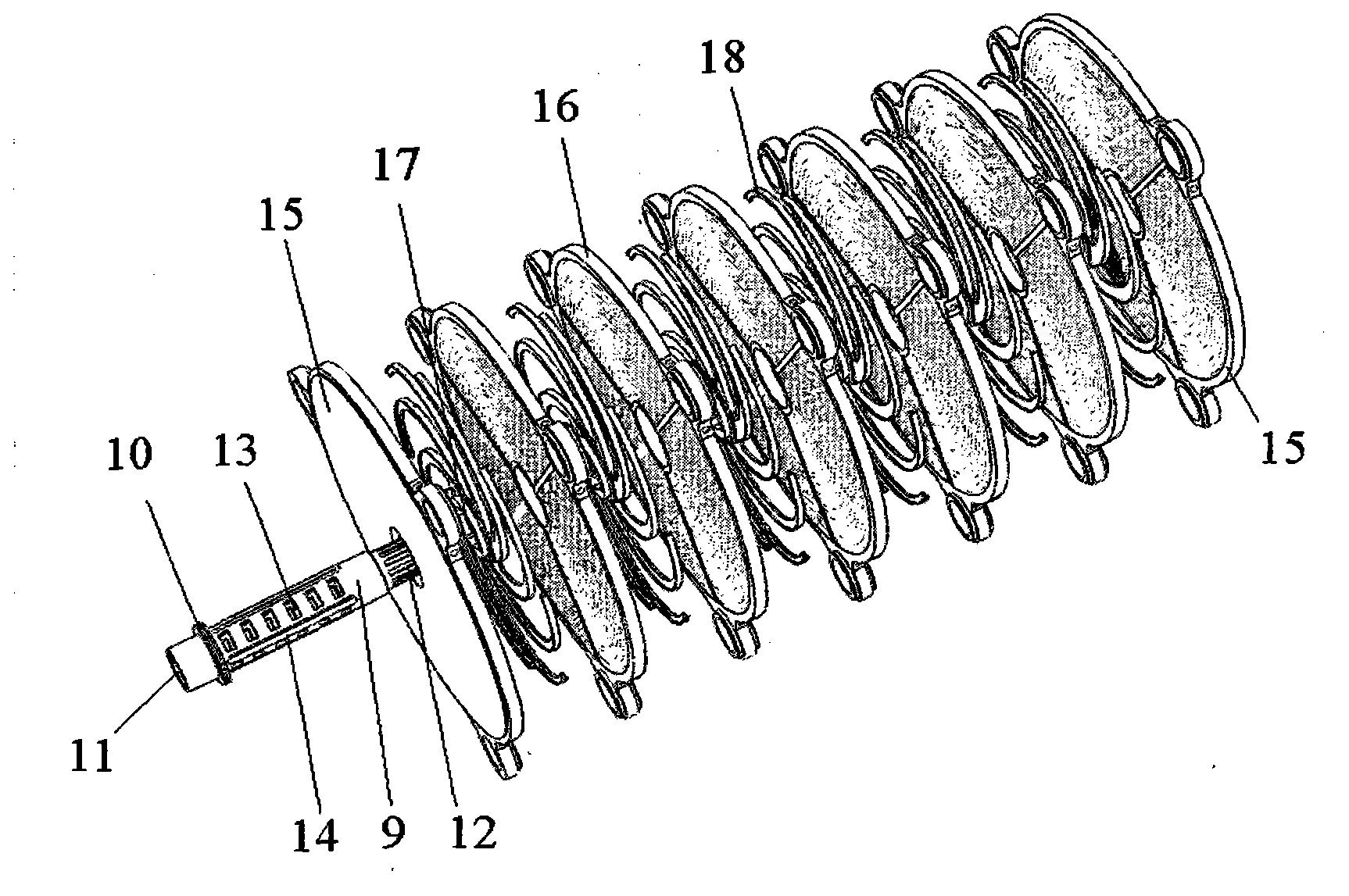

[0029] One end of the drive shaft (9) is provided with a positioning shoulder (10), and the other end is a spline shaft head (12); the shaft end provided with the positioning shoulder (10) has a pulp injection hole (11); the pulp injection The peripheral surface of the hole (11) is provided with 6 groups of outlets (13) distributed at equal intervals in the axial direction, and each grou...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap