Argil-grease blending tank

A technology of oil mixing and white clay, applied in mixers, edible oil/fat, fat oil/fat refining, etc., can solve the problems of white clay agglomeration, deposition, clogging, etc., to prevent agglomeration, improve uniformity and mixing efficiency , mixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

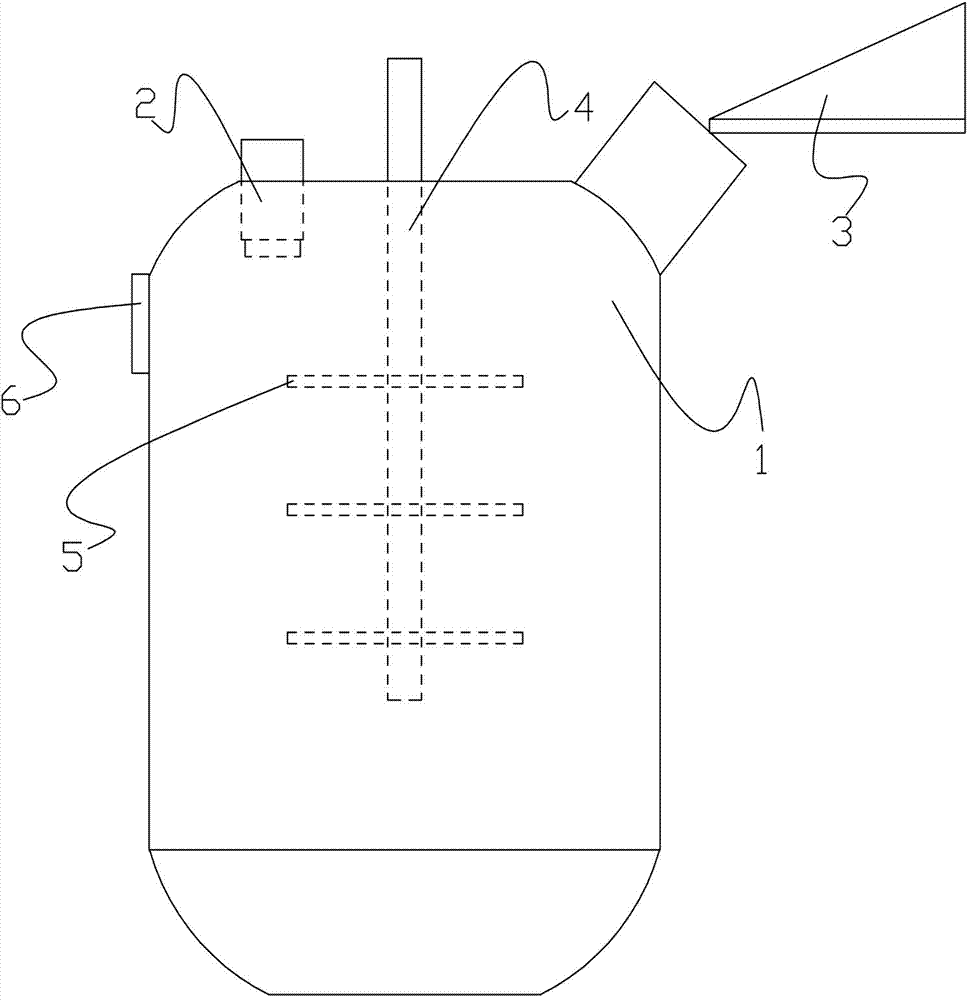

[0010] refer to figure 1 , clay oil mixing tank, including a cylindrical tank 1, a vibrating screen 3 outside the tank 1 and an injector 2 inside the tank 1, and the bottom of the tank 1 is conical.

[0011] The top of the tank body 1 is also provided with a feed port and an oil inlet port, the feed port is connected to the output port of the vibrating screen 3, and the oil inlet port is connected to the injector 2; the top of the tank body 1 is axially inserted with a stirring shaft 4, and the stirring shaft 4 is sealed with the tank body 1, the stirring shaft 4 is driven by a motor, and three stirring paddles 5 are installed on the insertion end of the stirring shaft 4 with the same spacing, the spacing is 20cm, and the blades of the stirring paddles 5 have through holes. A vacuum tube is installed on the tank body 1, and the vacuum tube is externally connected to a vacuum pump 6.

[0012] When in use, the grease-shaped injector 2 sprays out, and the clay is vibrated and cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com