Cubic hydraulic machine

A six-sided top hydraulic, steel plate technology, applied in the application of ultra-high pressure process and other directions, can solve the problems of inability to eliminate the fear of operators and maintenance personnel, disability, etc., to improve reliability and safety, prevent falling off or disintegration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

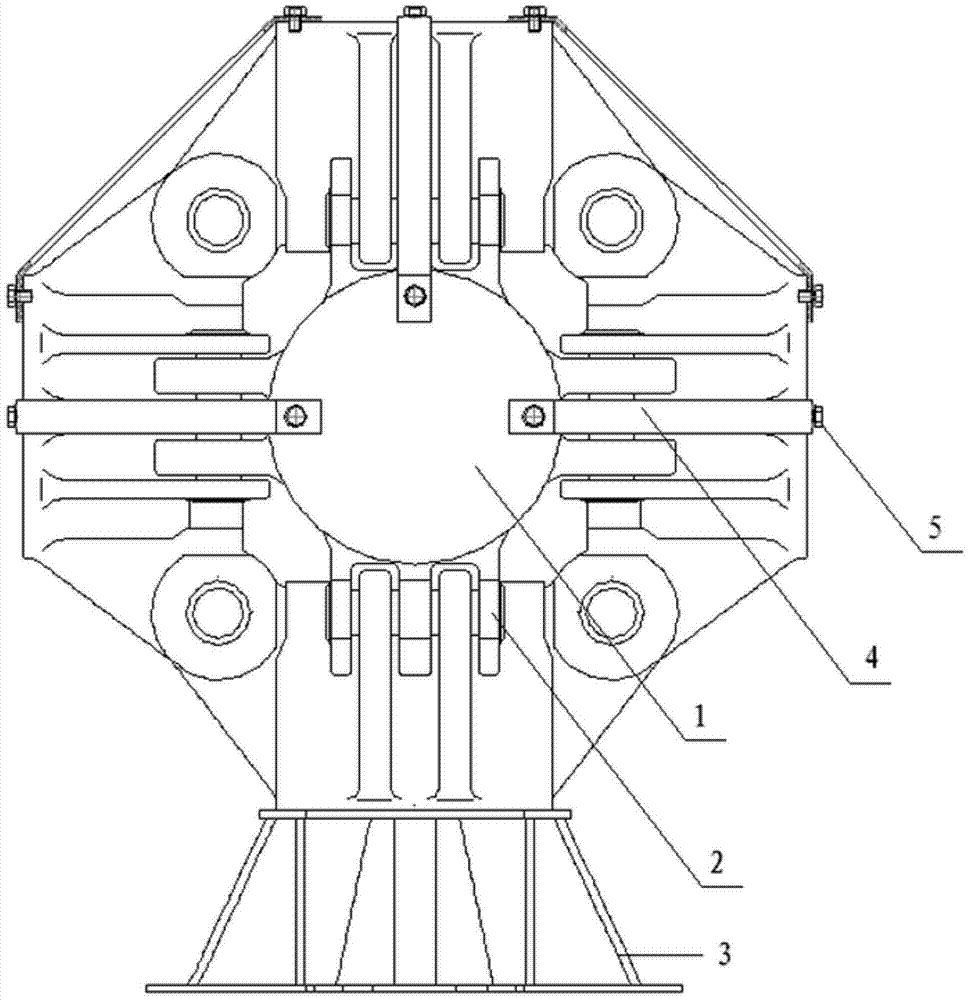

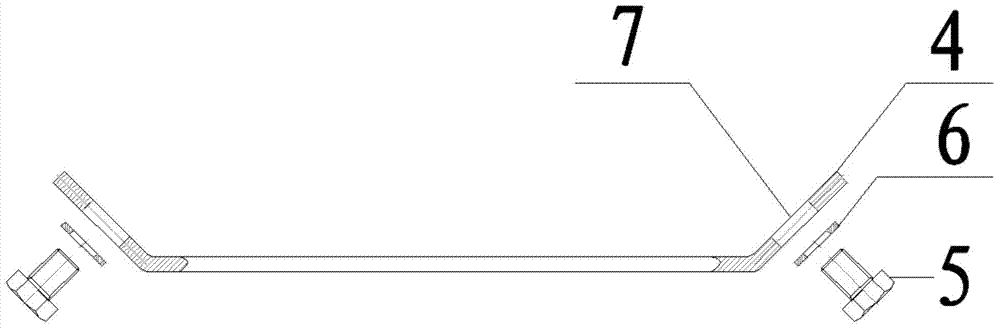

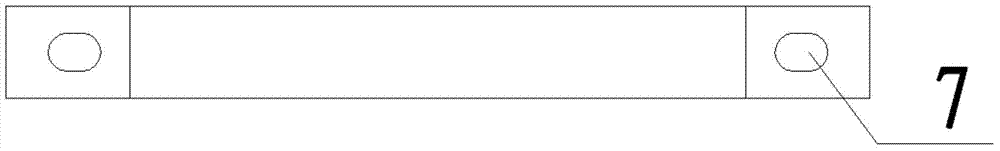

[0015] Such as figure 1 As shown, it includes six hinged beams 1 that are symmetrically distributed in front, rear, left, right, up and down. , gasket 6 and bolt 5, the two ends of the steel plate 4 are tilted, and the tilted position of the steel plate 4 is provided with a long hole 7, and the maximum radial dimension of the long hole 7 is greater than the diameter of the stud on the bolt 5 To the size, the adjacent hinge beam 1 is provided with a screw hole corresponding to the long hole 7 on the steel plate 4, the gasket 6 matches the long hole 7, and the size of the stud on the bolt 5 is the same as the screw hole The dimensions match, the radial dimension of the head of the bolt 5 is greater than the radial di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com