Dust removing device and chassis adopting dust removing device

A technology of dust removal device and chassis, which is applied in the direction of external electrostatic separator, electrode structure, electrostatic separation, etc., can solve the problems of not compact structure of dust removal device, unfavorable miniaturization of chassis, and influence of heat dissipation inside the chassis, so as to achieve compact structure, reduce Small occupied space, improve the effect of dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

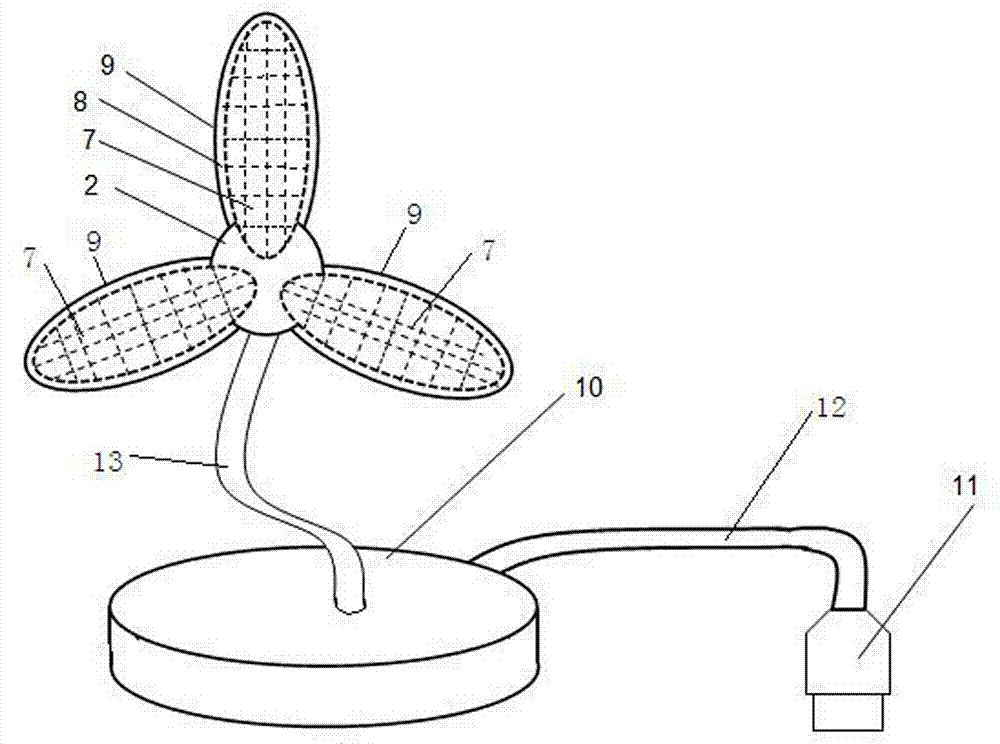

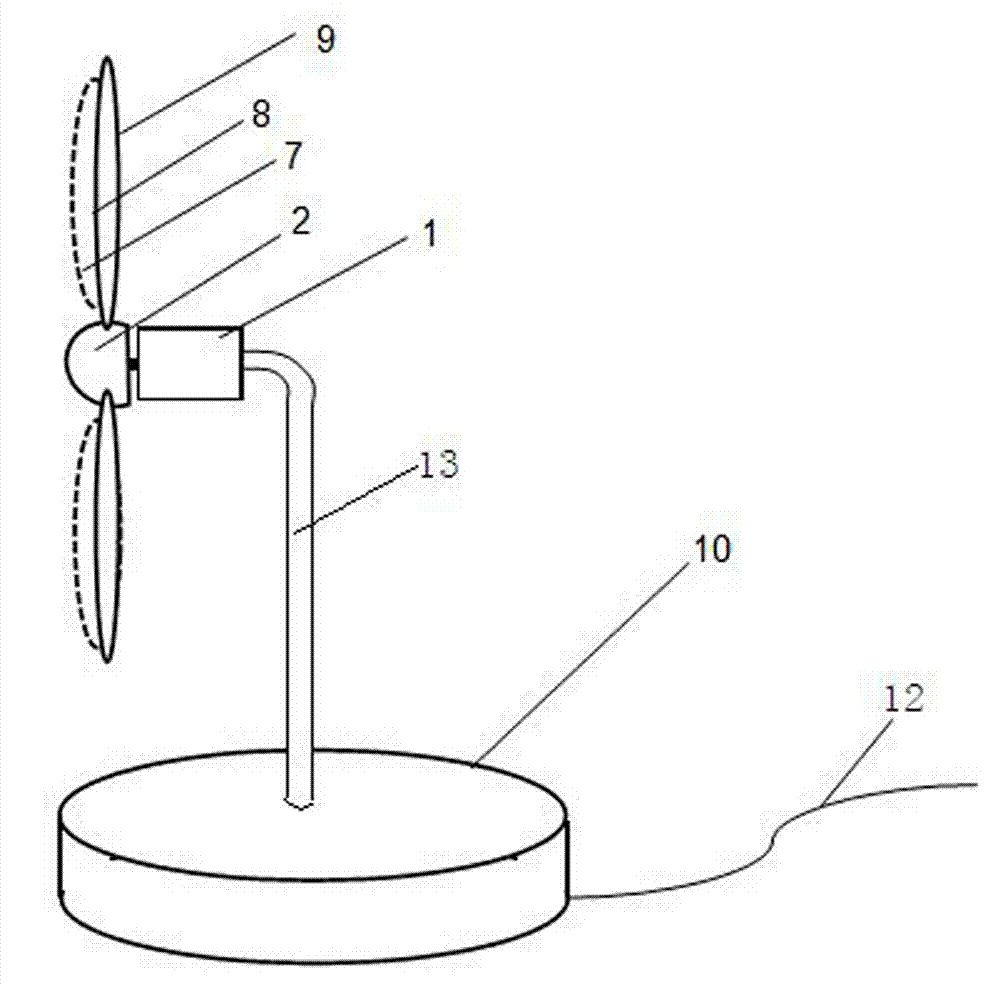

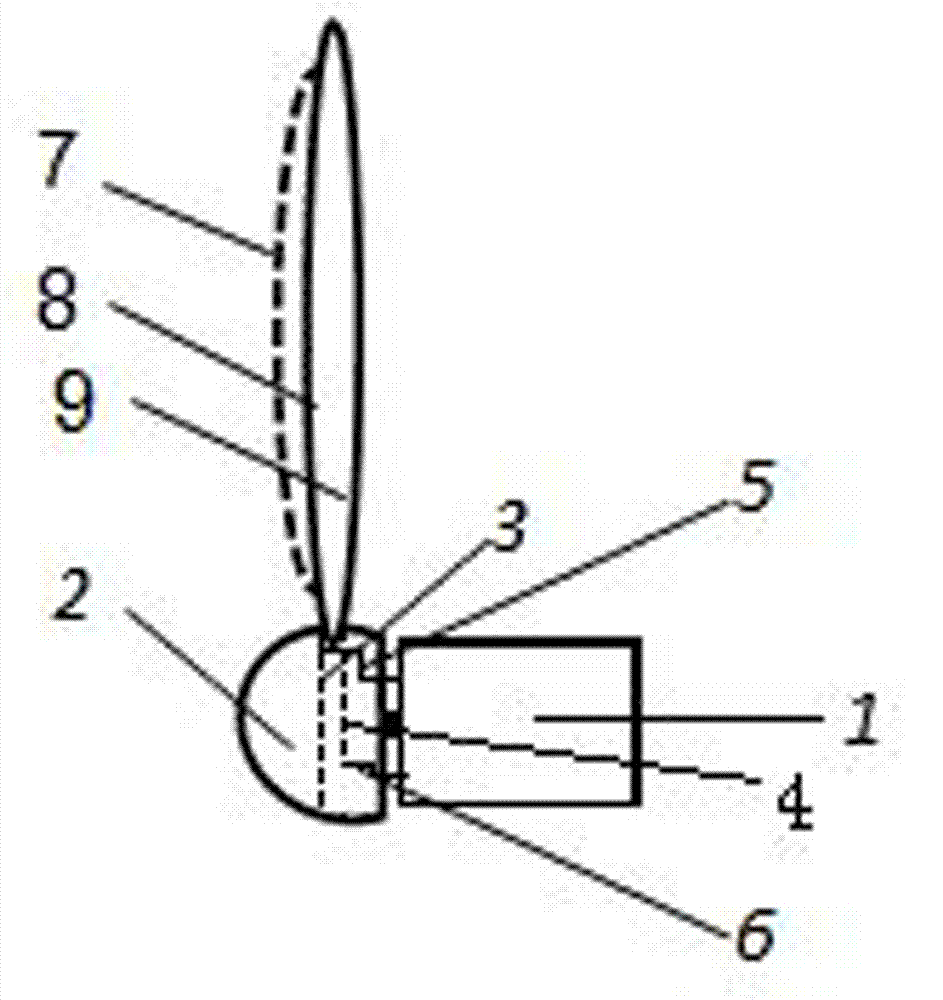

[0020] An example of a chassis is Figure 1~3 As shown: it includes a box body (not shown in the figure) provided with a dust removal device. The dust removal device includes a motor 1. The motor has a motor shaft whose axis extends along the front and rear directions. A fan is arranged on the motor shaft. The fan includes The fan base 2 and three fan blades 9 evenly distributed on the outer periphery of the fan base, the front end of each fan blade is fixed with a negative pole net 7, and the front end of the fan blade is also fixed with a positive electrode adsorption layer corresponding to each negative pole net 8. The areas of the negative grid and the positive adsorption layer are both smaller (or equal) to the area of the corresponding fan blade. Each positive adsorption layer is insulated from the corresponding negative grid. Each positive adsorption layer is located on the back side of the corresponding negative grid. The positive adsorption layer consists of It cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com