Automatic press fitting machine for engine valve oil seals and valve spring gaskets

A technology of engine valves and valve springs, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of automatic loading and simultaneous automatic assembly of engine valve oil seals and valve spring gaskets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

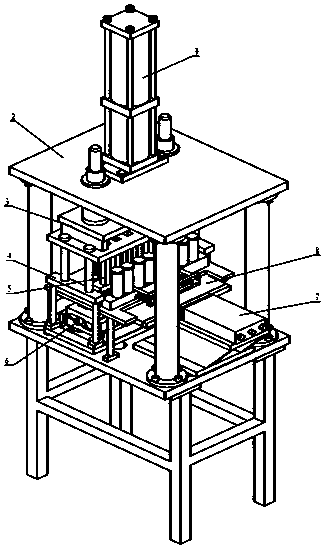

[0029] see figure 2, the present invention includes an oil seal delivery mechanism 5, a gasket delivery mechanism 8, a press-fit mechanism 3, a bracket 4, a fixing seat 2, a cylinder assembly 7 and a gas-liquid booster cylinder 9, and the oil seal delivery mechanism 5, the gasket The material transport mechanism 8, the press-fit mechanism 3 and the cylinder assembly 7 are all installed on the fixed seat 2, and the fixed seat 2 is installed on the horizontal plane, and the described bracket 4 is assembled with the press-fit mechanism 3, and the bracket 4 is used for carrying The engine cylinder head 6, the cylinder assembly 7 provides power for the oil seal delivery mechanism 5 and the gasket delivery mechanism 8, and the gas-liquid booster cylinder 9 is installed on the top of the press-fit mechanism 3, and it provides the press-fit mechanism 3 power.

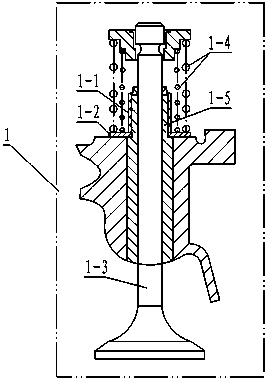

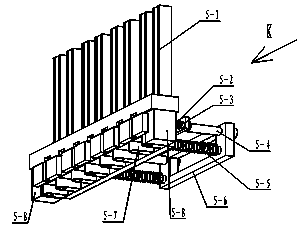

[0030] see image 3 , Figure 4 , Figure 5 , the oil seal delivery mechanism 5 of the present invention includes an oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com