A non-standard equipment structure layout method and the structure and non-standard equipment

A kind of equipment and non-standard technology, which is applied in the direction of metal processing equipment, other manufacturing equipment/tools, metal processing, etc., can solve the problems of complex loading and unloading layout, large occupied area, high cost, etc., and achieve standardization of design, reduction of occupied area, The effect of increased labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

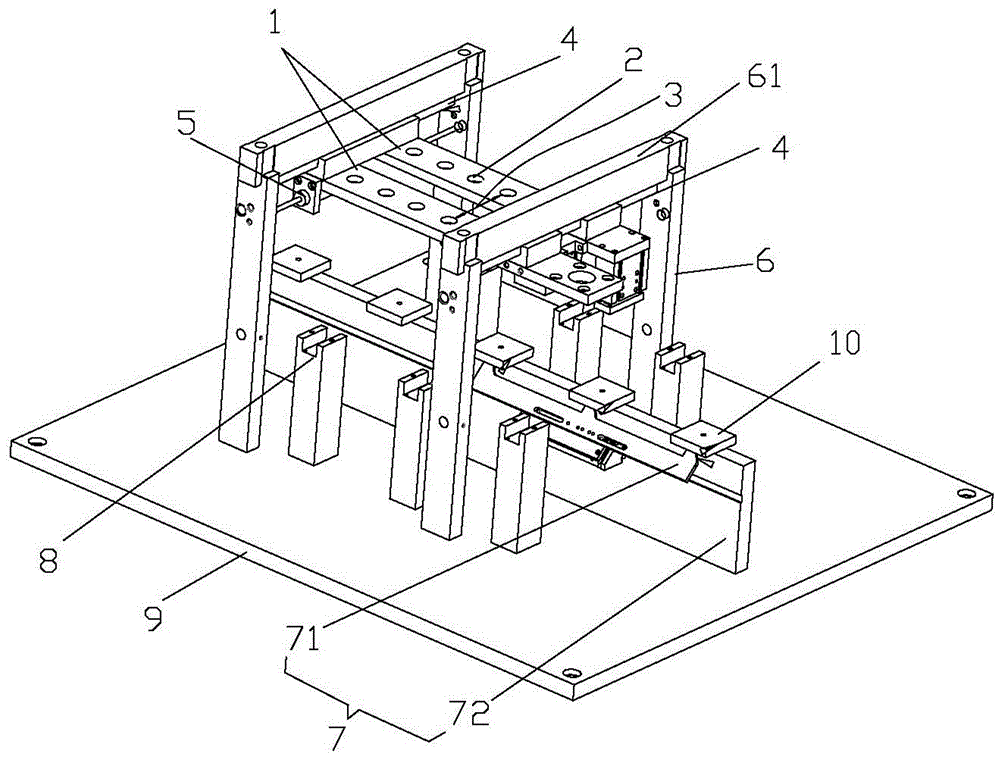

[0034] Such as figure 1As shown, a non-standard equipment structure, including a plurality of process positions with at least two process positions 2 described in the non-standard equipment structure layout method, each of the process positions 2 includes a corresponding device for completing a specific process To complete a specific process (the specific process is one or more items in picking and placing, processing parts and testing parts, etc.); a conveying device 7 is also set below the process position 2, and the conveying device 7 will be The processed parts 10 are transported to the process positions 2 in turn; a plurality of the process positions 2 are arranged in parallel with two straight rows with a certain distance 3, and the number and positions of the process positions 2 on the two straight rows correspond one by one, Form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com