Automatic assembling machine for electronic heads of piezoelectric ceramic igniters

A piezoelectric ceramic and electronic head technology, applied in the field of automatic assembly machines, can solve the problems affecting product output and quality stability, wasting manpower and material resources, and low production efficiency, so as to improve market competitiveness, save production costs and production efficiency. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

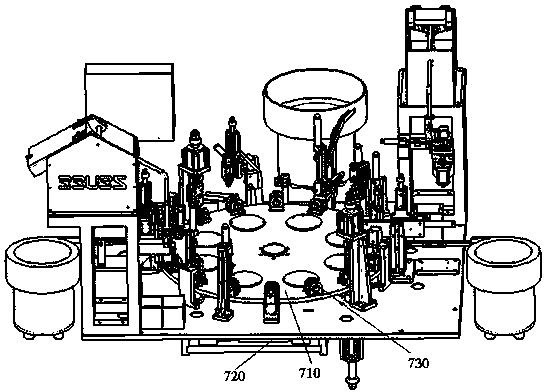

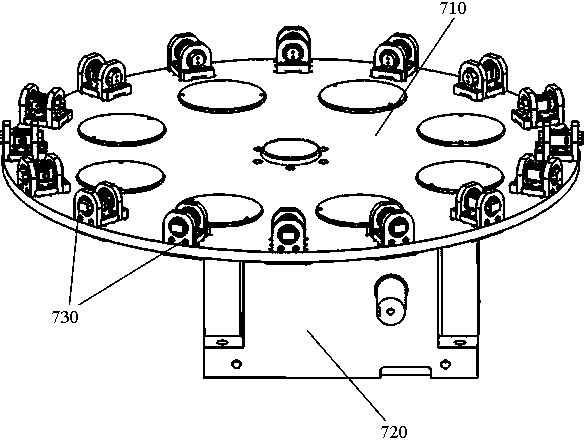

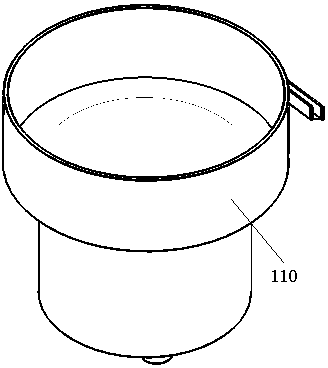

[0030] Such as figure 1 Shown is a schematic structural view of the automatic assembly machine used for the electronic head of the piezoelectric ceramic igniter in the present invention. The automatic assembly machine for the electronic head of the piezoelectric ceramic igniter includes a plastic three-way conveying device, an automatic glue dispensing device, a crystal transmission device, an iron head transmission device, an iron head pre-pressing and sealing device, and a plastic three-way rotating device , iron tail transmission device, iron tail preloading and sealing device, electronic head discharge device, automatic circulation device and control system, the plastic three-way conveying device is used to transport the plastic thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com