Method and system for recovering PTFE (Polytetrafluoroethylene) fibers and PPS (Polyphenylene Sulfide) in waste dust removing bag

A recycling method and dust bag technology, applied in the field of designing dust bag recycling, can solve the problems of high unit price, high price of dust bag, and difficult PTFE treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

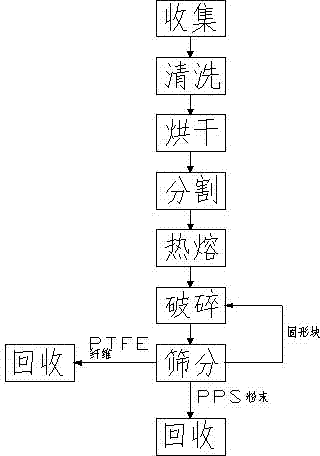

[0022] The technical solution of the present invention will be described below in conjunction with the accompanying drawings. Apparently, the accompanying drawings describe only a part of the present invention rather than all embodiments.

[0023] Such as figure 1 Shown, a kind of method that the present invention provides reclaims PTFE fiber and PPS in waste dust bag, comprises the following steps:

[0024] 101: Hot melting, at a temperature of 250°C-260°C, hot melt the waste dust bag until the PPS is completely melted;

[0025] 102: Breaking, breaking the solid block after the hot melt is cooled to a mixture of powder, fiber, and block solid matter;

[0026] 103: Sieve, sieve the mixture, recover the PTFE fiber and PPS powder, and return the blocky solid to step 102.

[0027] Under normal conditions, the melting point of PPS is 281°C. In the present invention, 250°C-260°C is selected because the performance of PPS in the discarded dust bag after long-term use has decreased...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com